Polymer emulsion paint for sucking electromagnetic wave and prepn. method

A polymer emulsion, electromagnetic wave absorption technology, applied in radiation absorbing coatings, chloroprene homopolymer coatings, coatings, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

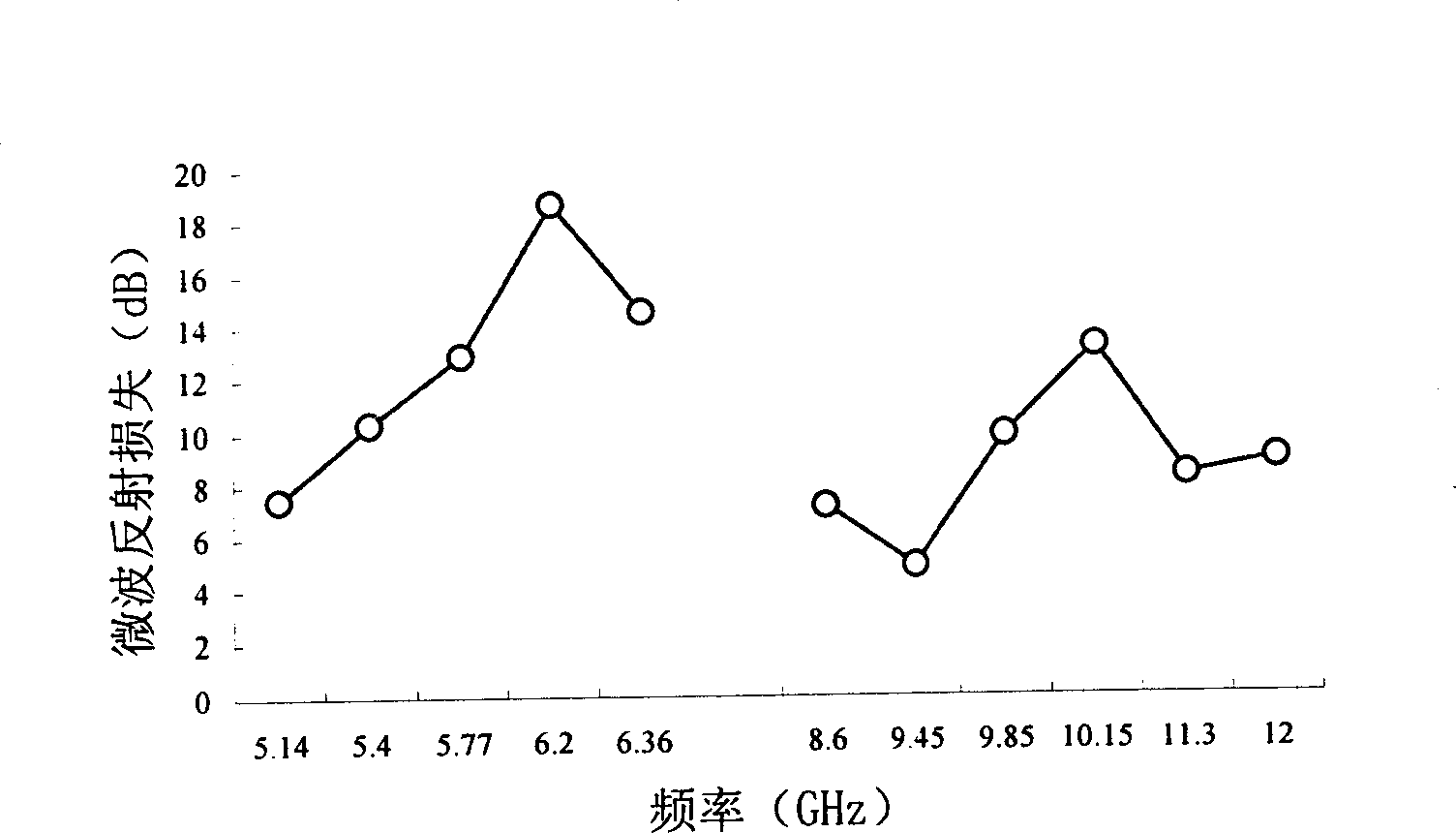

Image

Examples

Embodiment 1

[0015] 1. Preparation of wave-absorbing base coating:

[0016] (1) Mixing ratio by mass: hydroxyethyl cellulose 3g, ethylene glycol 25g, water 180ml, styrene-acrylic acid emulsion 320ml, NXL defoamer 3ml, nickel powder 100g, carbon fiber (2mm) 125g, dispersant (5027 ) 5g, alcohol ester twelve 6g weigh (measure) and get each raw material respectively;

[0017] (2) Stir evenly to obtain a polymer coating.

[0018] 2. Preparation of wave-absorbing surface coating:

[0019] (1) Mixing ratio by mass: hydroxyethyl cellulose 3g, ethylene glycol 25g, water 180ml, styrene-acrylic acid emulsion 320ml, NXL defoamer 3ml, ferrite powder 300g, dispersant (5027) 5g, alcohol Ester twelve 6g is weighed (amount) to get each raw material respectively;

[0020] (2) Stir evenly to obtain a polymer coating.

[0021] 2. Application of coating

[0022] (1) Clean up the wall of the building to make the wall clean and smooth.

[0023] (2) Use a roller or brush to apply the wave-absorbing primary ...

Embodiment 2

[0029] 1. Preparation of absorbing coating:

[0030] (1) Mixing ratio by mass: hydroxyethyl cellulose 3g, ethylene glycol 25g, water 185ml, acrylic emulsion 300ml, NXL defoamer 3ml, ferrite powder 300g, dispersant (5027) 5g, alcohol ester twelve 6g were weighed (measured) to take each raw material;

[0031] (2) Stir evenly to obtain the polymer coating for use.

[0032] 2. Application of coating

[0033] (1) Clean up the wall of the building to make the wall clean and smooth.

[0034] (2) Apply wave-absorbing paint on the wall with a roller or brush.

[0035] (3) The wave-absorbing coating is dried in the air to form a film with a thickness of 1mm.

[0036] (4) Apply wave-absorbing paint on the wall with a roller or brush.

[0037] (5) The wave-absorbing coating is dried in the air to form a film with a thickness of 1mm.

[0038] (6) Use a roller or a brush to coat the wall with ordinary commercial decorative paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com