Method for recovering methyl chloride from methyl chloride waste gas

A technology of methyl chloride and waste gas is applied in the field of waste gas treatment in chemical production, which can solve the problems of complicated operation and high energy consumption, and achieve the effects of high separation effect, low energy consumption and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

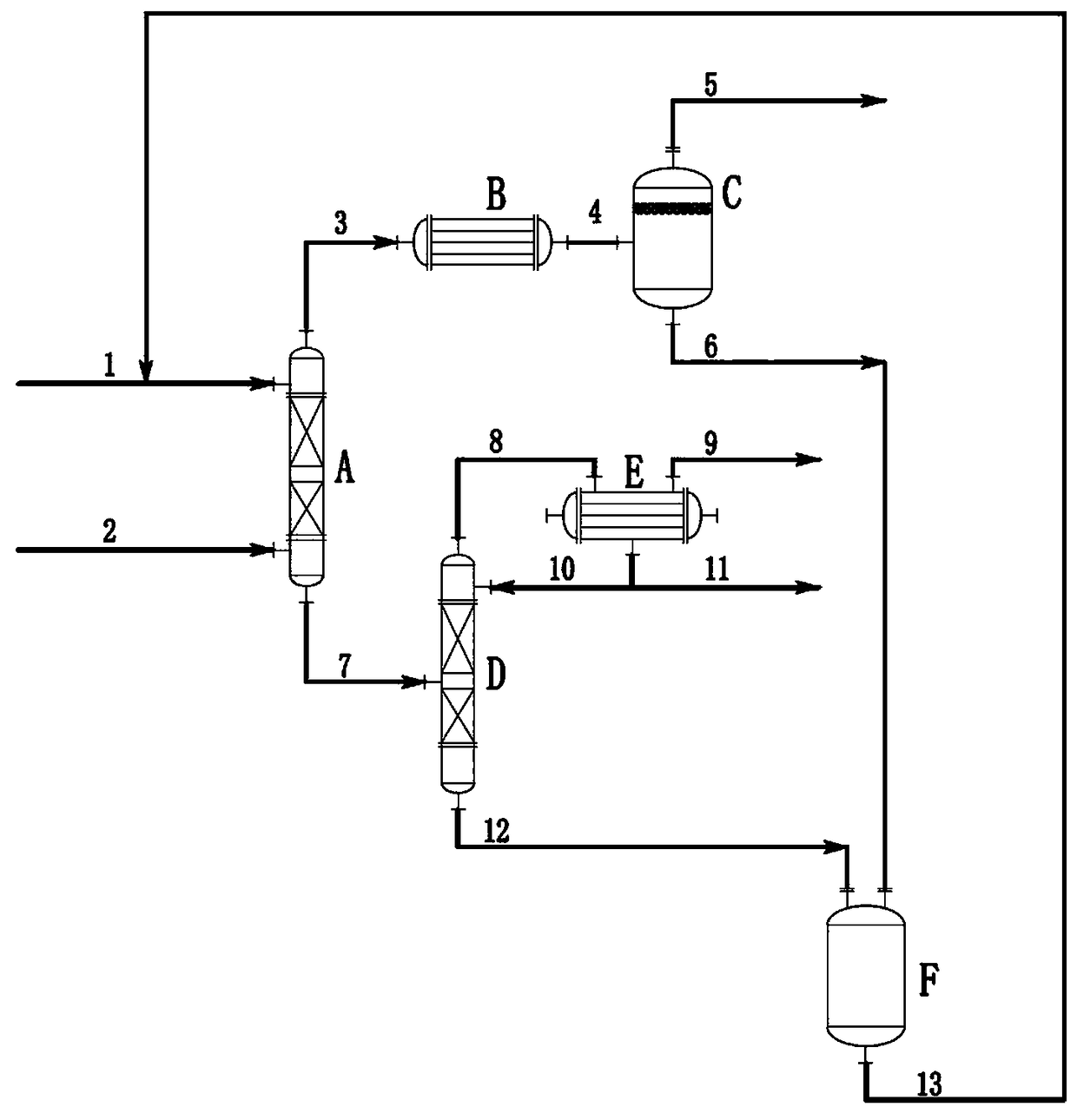

[0021] In this example, taking 80% mass fraction of methyl chloride waste gas (containing 20% nitrogen) as an example, the composition of the absorption liquid is: 1 / 3 benzene, 1 / 3 ethanol, and 1 / 3 dichloroethane , the amount of absorbing liquid is 10 times that of methyl chloride waste gas. The absorption liquid 1 at 20°C and the methyl chloride waste gas 2 at 0°C are fed continuously from the upper and lower parts of the pressurized absorption tower A respectively, and the absorption liquid absorbs methyl chloride through reverse contact. Nitrogen 3 is extracted from the top of the absorption tower, and absorption liquid 7 containing chloromethane and a trace amount of nitrogen is extracted from the bottom of the absorption tower. The operating pressure of the absorption tower is 3 bar, and the number of theoretical plates is 10.

[0022] The absorption liquid containing methyl chloride and trace nitrogen obtained at the bottom of the absorption tower is continuously fed ...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the composition of the absorption liquid is: 1 / 5 of benzene, 1 / 5 of ethanol, 3 / 5 of dichloroethane, and the amount of absorption liquid is 9 times that of the waste gas of methyl chloride. The absorption liquid with a mass fraction of 99.97% is extracted from the bottom of the rectification tower, and the liquid methyl chloride product with a mass fraction of 99.95% is extracted from the partial condenser.

Embodiment 3

[0027] The difference between this embodiment and Embodiment 1 is that the absorption liquid only contains ethylene dichloride, and the amount of absorption liquid is 8 times that of the waste gas of methyl chloride, and the absorption liquid with a mass fraction of 99.99% is extracted from the bottom of the rectification tower. The condenser extracts a liquid methyl chloride product with a mass fraction of 99.99%.

[0028] It should be further explained that: in the present invention, any one of benzene, ethanol, and dichloroethane can be used as the absorbing liquid, or any combination of any two or three in any proportion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com