Carbon black reinforced metal-based micro-nano powder with high light absorbing property and preparation method thereof

A high light-absorbing, metal-based technology is applied in the field of metal-based micro-nano powder for laser remanufacturing and its preparation, carbon black-enhanced high-light-absorbing metal-based micro-nano powder and its preparation field, and can solve the problem of low laser absorptivity and so on. , to achieve the effect of good application prospect, good mechanical properties and narrow heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036]Materials used in this example: the average particle size of the nano carbon black powder is 14 nm, the coloring strength is 140%, and the mass fraction is 1%; the micron metal powder is Al-Si alloy powder, the average particle size is 50 μm, and the mass fraction is 99% Using the above method and steps to prepare carbon black reinforced high light-absorbing metal-based micro-nano powder, the ball-milling compound parameters are that the ball-milling speed is 200 rpm, the ball-to-material ratio is 10:1, and the ball-milling time is 1 hour.

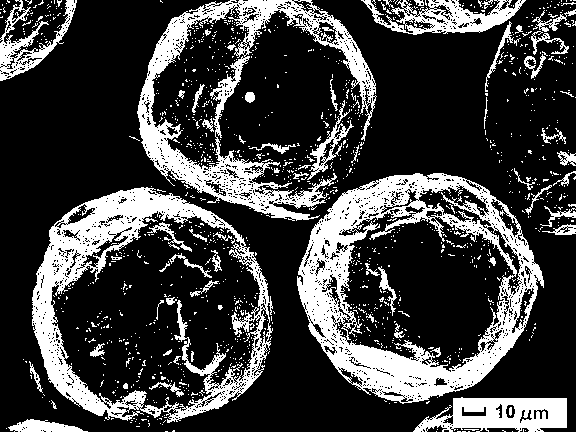

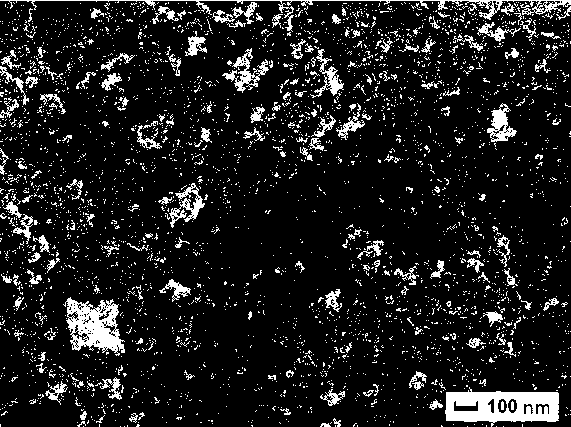

[0037] Observed by scanning electron microscope, the prepared micro-nano powder maintains the spherical characteristics of micro-nano powder ( figure 1 ), and its surface is coated with a large number of nano-carbon black powders with high dispersibility ( figure 2 ) to form the core-shell structure of the present invention. The micro-nano powder is used for laser welding to remanufacture 0.6mm thick thin-walled parts with penetrat...

example 2

[0039] Materials used in this example: the average particle size of nano-carbon black powder is 28nm, the coloring strength is 100%, and the mass fraction is 1.5%; the micron metal powder is Ni60 alloy powder, the average particle size is 75 μm, and the mass fraction is 98.5%; The method steps are to prepare carbon black-enhanced metal-based micro-nano powder with high light absorption. The core-shell structure features of the invention, and its practical use effect also achieves the purpose of the invention.

example 3

[0041] Materials used in this example: the average particle size of nano-carbon black powder is 22 nm, the coloring strength is 125%, and the mass fraction is 0.5%; the micron metal powder is iron-based F103 alloy powder, the average particle size is 60 μm, and the mass fraction is 99.5%; The above method and steps are used to prepare carbon black reinforced metal-based micro-nano powder with high light absorption. It has the features of the core-shell structure of the present invention, and its practical use effect also achieves the purpose of the present invention.

[0042] The above only lists several common carbon black-enhanced high light-absorbing metal-based micro-nano powders. Those skilled in the art can select different micron metal powders according to the remanufactured thin-walled material, and then follow the proportions and With the preparation method, ideal metal-based micro-nano powders with high light absorption and enhanced by carbon black suitable for the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com