Wave-absorbing invisible bulletproof plate of integrated structure and preparation method of wave-absorbing invisible bulletproof plate

A bulletproof plate and bulletproof layer technology, applied in chemical instruments and methods, protective equipment, protective equipment, etc., can solve problems such as high areal density, and achieve the effects of improving ballistic resistance, reducing impact, and improving wave absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

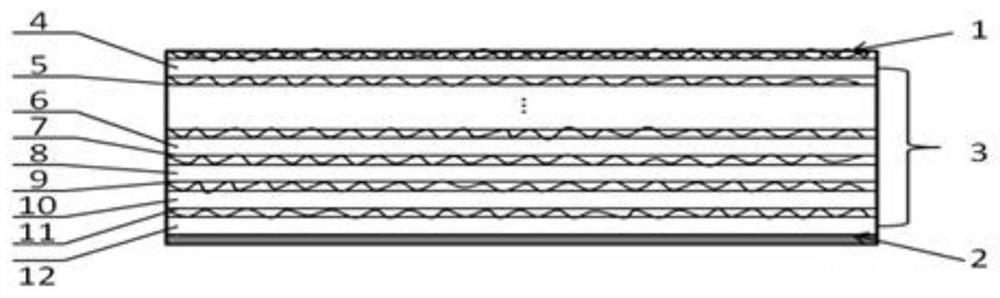

[0049] A preparation method of the integrated stealth bulletproof plate of the above-mentioned present embodiment, comprising the following steps:

[0050] Preparation of the stealth bulletproof layer: In the mold, a 3.0mm thick UHMWPE fiber-reinforced polyethylene-based composite material, a 0.02mm resistance film for the first wave-absorbing material layer, and a 4.0mm thick UHMWPE fiber-reinforced polyethylene composite material were sequentially laid in the mold. Vinyl composite material, the second absorbing material layer resistive film 0.02mm, 4.9mm thick ultra-high molecular weight polyethylene fiber reinforced polyethylene-based composite material, the third absorbing material layer resistive film 0.02mm, 5.5mm thick ultra-high The molecular weight polyethylene fiber-reinforced polyethylene-based composite material, the fourth wave-absorbing material layer resistance film 0.02mm, and the 5.9mm thick ultra-high molecular weight polyethylene fiber-reinforced polyethylene...

Embodiment 2

[0055] A preparation method of the integrated stealth bulletproof plate of the above-mentioned present embodiment, comprising the following steps:

[0056] Preparation of the stealth bulletproof layer: In the mold, a 3.2mm thick aramid fiber epoxy resin-based composite material, the first absorbing material layer resistance film of 0.02mm, a 3.4mm thick aramid fiber epoxy resin based composite material, and the second The second wave-absorbing material layer is a supermaterial film of 0.3mm and 3.6mm thick aramid fiber epoxy resin-based composite material, which is hot-pressed at 80°C to form a stealth bulletproof layer.

[0057] Preparation of the stealth bulletproof board: the stealth bulletproof layer, the 0.4mm glass steel plate layer, and the 0.2mm carbon fiber composite material layer are bonded from top to bottom, and the glued integrated structure of the stealth bulletproof board is pressed at 70°C for a pressing time of After 60 minutes, the integrated structure of th...

Embodiment 3

[0061] The iron-coated carbon fiber magnetic material film was prepared as follows:

[0062] S1 Cut the carbon fiber into 30cm long, then knot the two ends of the carbon fiber, put the knotted fiber into the tube furnace, burn at a high temperature of 500°C for 40min, take it out after cooling; cut into chopped carbon fiber;

[0063] S2 carbon fiber is dried at 80°C for 10 hours;

[0064] S3 is a closed reaction kettle, add about 2 / 3 of the solvent to each of the six gas washing bottles, pass nitrogen, and use soapy water to test whether the lid of the reaction kettle is leaking. If there is no bubble, the reaction kettle is sealed and qualified.

[0065] S4 Add 500 g of carbon fiber and 12 kg of solvent xylene into the barrel, and disperse with a disperser at a high speed of 800 rpm for 30 min.

[0066] S5 adds the dispersed xylene fiber soaking solution into the reaction kettle; weighs a certain amount of iron pentacarbonyl into the reaction kettle, rinses the carbonyl iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com