Quality factor controllable shearforce detection controller

A technology of detection control and quality factor, applied in the field of scanning near-field optical microscopy, which can solve the problems of low quality factor, unreachable, high detection sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

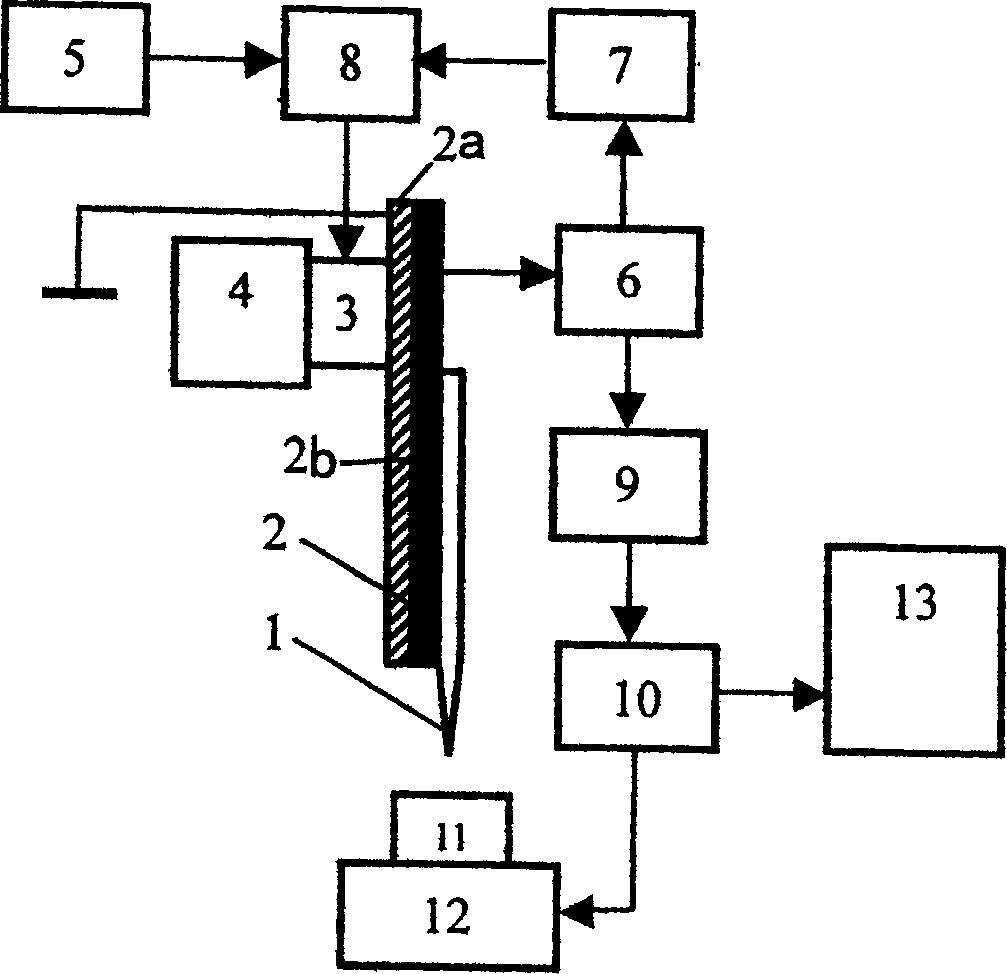

[0026] see figure 1 . The asymmetric piezoelectric bimorph 2 with a thickness of 0.4 mm is cut and ground to make a rectangular sheet with a length of 14 mm and a width of 1.5 mm. One end (one side of the metal sheet) of the piezoelectric bimorph 2 is glued on the piezoelectric ceramic block 3 on the scanning probe microscope body 4, and a section of the metal sheet 2a with a length of 2 mm is reserved for grounding, and the other end forms a Cantilever beam 2b. Probe 1 is an optical fiber probe, which can be made of single-mode or multi-mode optical fiber by chemical etching or heating and stretching, and bonded to the cantilever beam 2b of the asymmetric piezoelectric bimorph 2, that is, the piezoelectric bimorph On the piezoelectric sheet of the wafer 2 (on the surface of the ceramic sheet), one end of the optical fiber stretches out about 1 mm of the asymmetric piezoelectric bimorph as the probe 1, and the other end of the optical fiber is coupled with a photodetector su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com