Use of tetrafluoro resin on art treasure protection

A technology of cultural relics protection and tetrafluororesin, which is applied in the direction of preservation of paintings, decorative arts, coatings, etc., can solve the problems of unstable chemical structure, insufficient wear resistance and hardness of fluorine rubber, and achieve beyond anti-oxidation performance and excellent weather resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

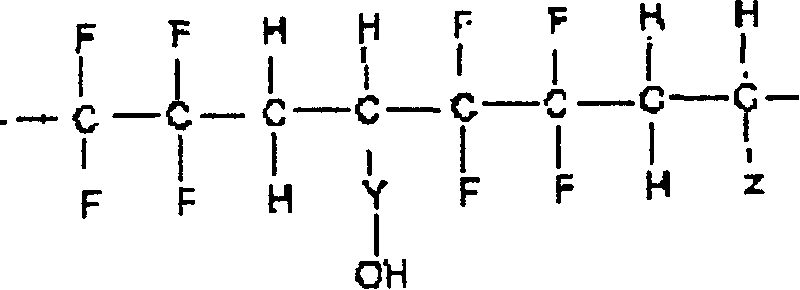

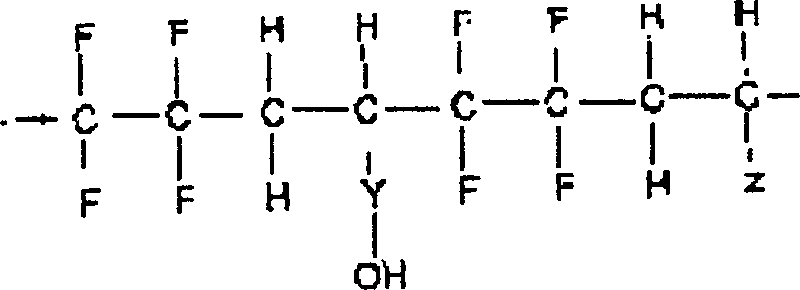

Method used

Image

Examples

Embodiment 1

[0021] 1. Main agent components (weight ratio): 74% tetrafluororesin, 0.4% defoamer, 0.2% polydimethylsiloxane solution, 0.6% special ultraviolet light absorber, 0.3% special composite vinyl oxide , fumed silica 6%, butyl acetate 4.5%, mixed high boiling point solvent 7%, xylene 3%, 100 # Solvent preparation 4%;

[0022] The main ingredient components are obtained through the following preparation process:

[0023] a. Pour tetrafluororesin into the dispersion tank

[0024] b. Add defoamer, polydimethylsiloxane solution, special ultraviolet light absorber, and special composite vinyl oxide in sequence, and stir at a medium speed for more than 5 minutes until uniform;

[0025] c. Add functional matting filler under medium-speed stirring state, and disperse to a suitable fineness at high speed;

[0026] d. Add butyl acetate, mixed high boiling point solvent, xylene in sequence, and stir evenly;

[0027] e. use 100 # Solvent washing machine, adjust to the appropriate viscosit...

Embodiment 2

[0035]1. Main agent components (weight ratio): 70% tetrafluororesin, 0.4% defoamer, 0.2% special leveling aid solution, 0.6% special ultraviolet light absorber, 0.3% special composite vinyl oxide, diatom Soil or aluminum silicate 10%, butyl acetate 4.5%, mixed high boiling point solvent 7%, xylene 3%, 100 # Solvent preparation 4%;

[0036] The preparation method of above-mentioned main agent is identical with embodiment one;

[0037] 2. Crosslinking agent components (weight ratio): HDI polymer 80%, water absorbent 0.2%, inert filling gas 0.3%, solvent 19.5%;

[0038] The preparation method of described linking agent is identical with embodiment one;

[0039] 3. Diluent components (weight ratio): 30% xylene, 25% 100 # Solvent, 25% butyl acetate and 20% mixed high boiling point solvent. The above diluents are put into the tank in sequence and stirred evenly, then they can be packaged for use.

[0040] When using on site, first pour the main agent into the container, add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com