Method and apparatus for optic catalytic oxidizing, desulfurizing and denitrifying flue gas simultaneously

A photocatalytic oxidation, desulfurization and denitrification technology, applied in the field of flue gas desulfurization and denitrification, can solve the problems of huge operating cost, non-recyclable, easy to block pores, etc., achieve low manufacturing cost, low consumption, and increase the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

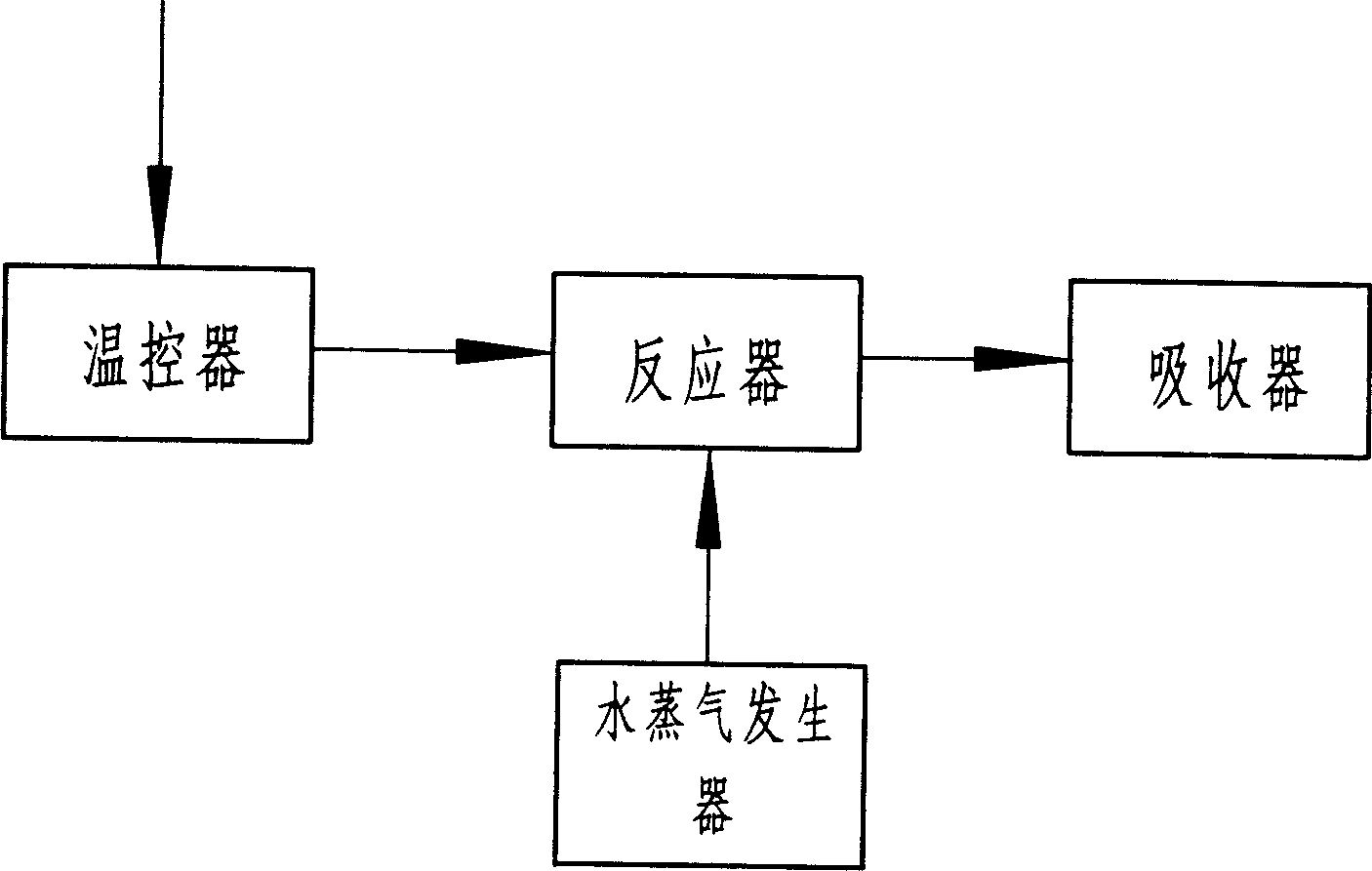

Method used

Image

Examples

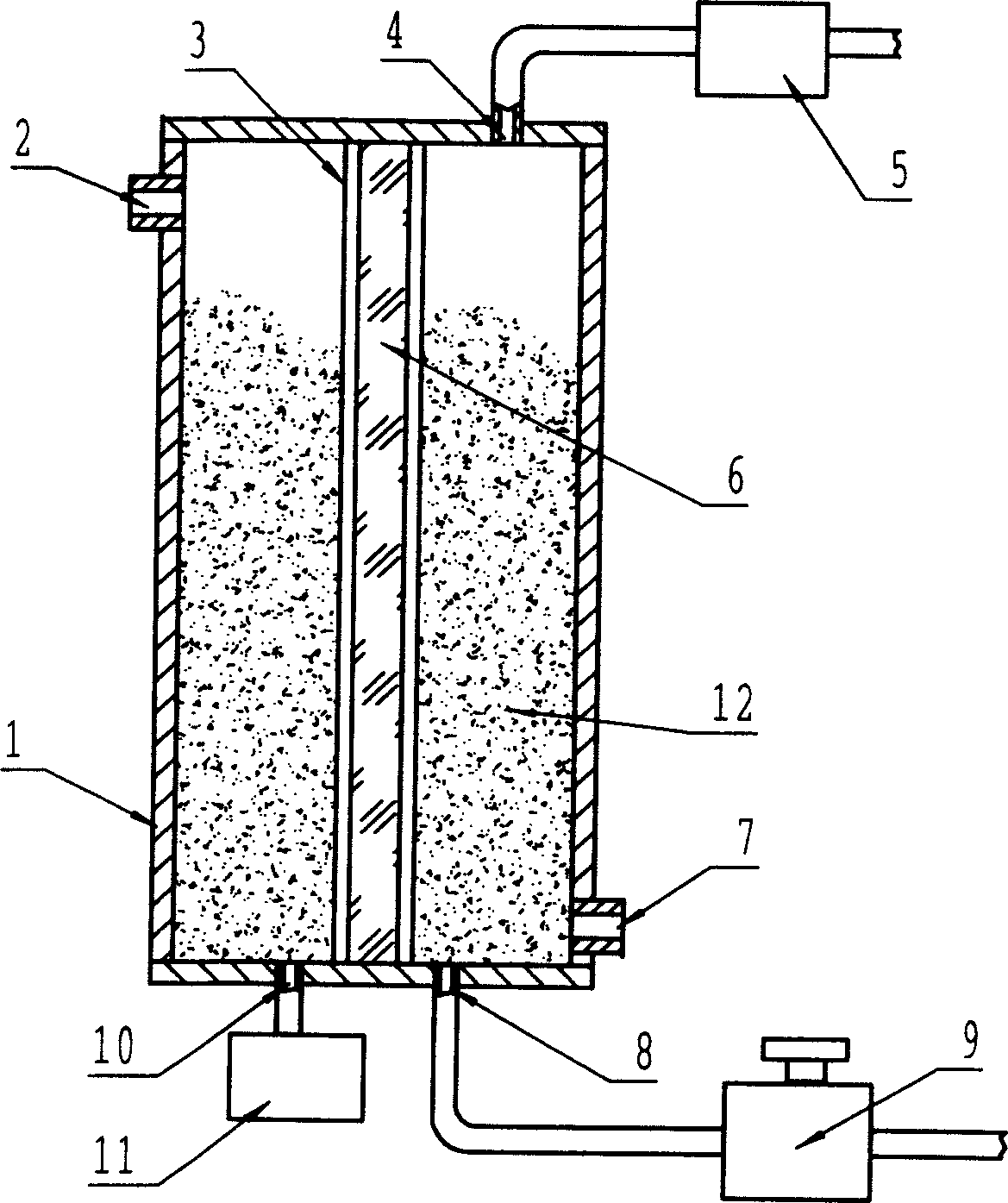

Embodiment 1

[0050] Prepare 0.1mol / L ammonium fluorotitanate ((NH 4 ) 2 TIF 6 ) And 0.3mol / L boric acid (H 3 BO 3 ) The mixed solution is a photocatalyst deposition solution, and 0.5% ZnO additive by mass is added to the deposition solution, deposited on the carrier quartz sand with a particle size of 4-6mm under the condition of a water bath at 40°C, and then taken out to dry after 45 hours. Raise the heating rate of 10℃ / min to 450℃ and burn for 30 minutes to obtain the supported TiO 2 catalyst of light. Catalytic reaction conditions: humidity is 3%, temperature is 70°C.

Embodiment 2

[0052] Prepare 0.1mol / L ammonium fluorotitanate ((NH 4 ) 2 TIF 6 ) And 0.3mol / L boric acid (H 3 BO 3 ) Photocatalyst deposition solution, and 0.5% Fe is added to the deposition solution 2 O 3 Additives are deposited on the carrier quartz sand with a particle size of 4-6mm under the condition of a water bath at 40°C. After 40 hours, they are taken out to dry, and heated at a rate of 10°C / min to 450°C for 30 minutes to obtain a supported type. TiO 2 catalyst of light. Catalytic reaction conditions: humidity is 10%, temperature is 60°C.

Embodiment 3

[0054] Prepare 0.1mol / L ammonium fluorotitanate (NH 4 ) 2 TIF 6 And 0.3mol / L boric acid H 3 BO 3 Photocatalyst deposition solution, and 0.5% Al is added to the deposition solution 2 O 3 Additives are deposited on the carrier quartz sand with a particle size of 4-6mm under the condition of a water bath at 40°C. After 45 hours, they are taken out to dry, and heated at a rate of 10°C / min to 450°C for 30 minutes to obtain a supported type. TiO 2 catalyst of light. Catalytic reaction conditions: humidity is 6%, temperature is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com