Method for extracting methyl o-phenylendiamine from TDI organic residue and synthesizing TTA using same

A technology for methyl-o-phenylenediamine and methylbenzotriazole, which is applied in the field of chemistry and achieves the effects of less by-products, easy control and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

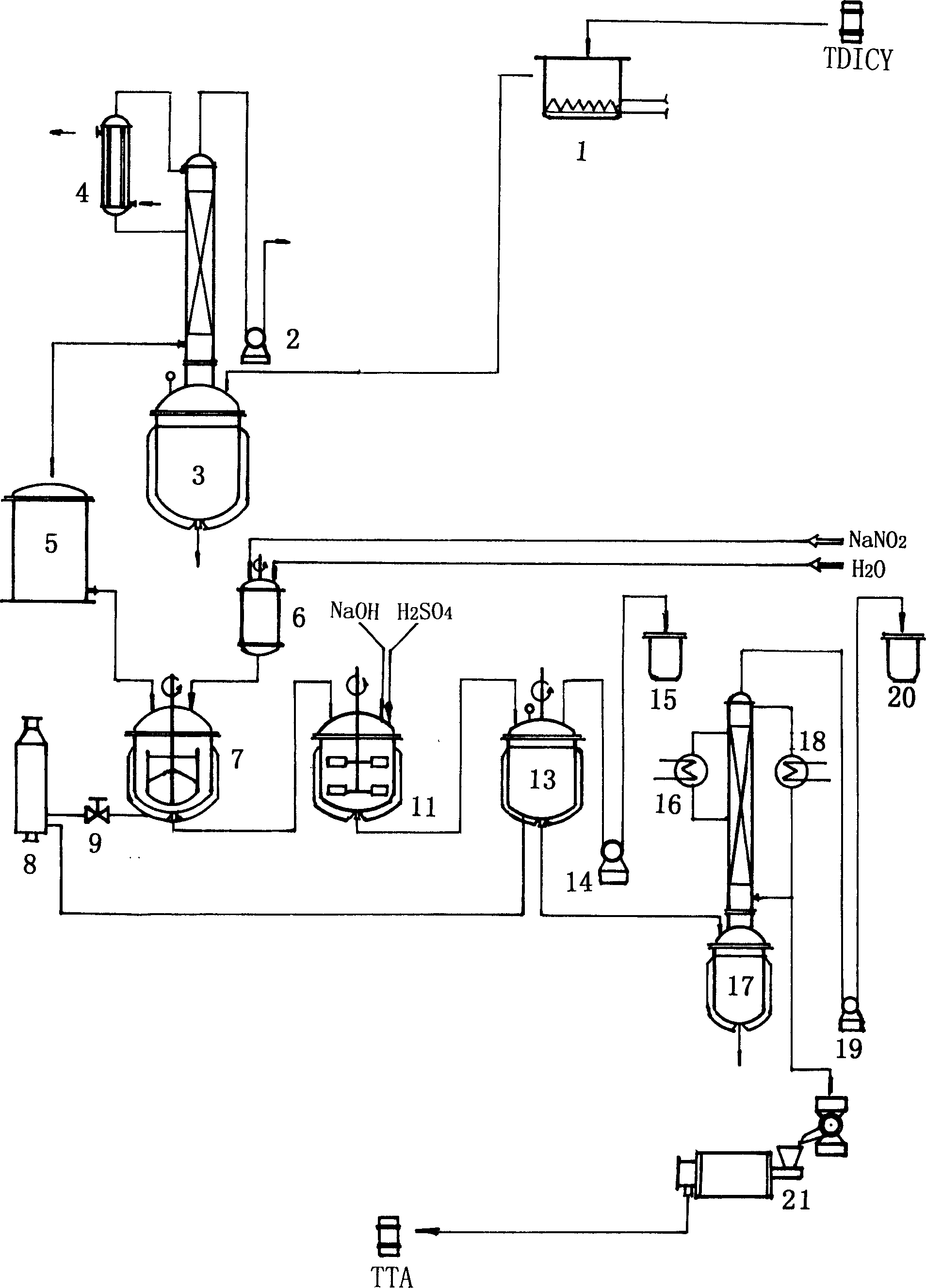

Image

Examples

Embodiment 1

[0024] Take 1700Kg of organic residue with 90% OTD content in TDI hydrogenated organic residue as an example. The organic residue is stored in a 200Kg iron drum. The specific extraction process is as follows:

[0025] a. Dissolution process: Put 1700Kg TDI organic residue in chemical material tank 1 first, open the steam heating valve to pass the heat source into chemical material tank 1, and control the chemical material water temperature at 85~90℃ for 9 hours, after the organic residue is completely dissolved , Sent to the purification and distillation still;

[0026] b. Purification and refining process: under the process conditions of controlling the organic residue material temperature in the purification and rectification kettle 3 at 172°C and the vacuum degree of 200Pa, the ratio of receiving and reflux is controlled to be 6.0:4.5, and the content of received methyl o-phenylenediamine is above 99.2% A total of 1516Kg of methyl o-phenylenediamine product with a content of 99...

Embodiment 2

[0028] Taking 2520Kg of organic residue with 97% OTD content in TDI hydrogenation residue as an example, the specific extraction procedure is as follows:

[0029] a. Dissolution process: Put 2520Kg of TDI organic residue into the chemical material tank 1, open the steam heating valve to pass the heat source into the chemical material tank 1, and control the chemical material water temperature at 90°C for 7.5 hours. After the organic residue is completely dissolved, Send to the purification and distillation process;

[0030] b. Purification and refining process: under the process conditions of the organic residue material temperature in the purification and rectification kettle 3 at 175°C and the vacuum degree of 180Pa, the receiving and reflux ratio is controlled to be 7.2:3.8, and the content of the received methyl o-phenylenediamine is more than 99.4%. A total of 2430Kg of methyl-o-phenylenediamine product with a content of 99.43% was extracted, and the recovery rate was 99.41%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com