Incinerator for urban refuse granular fuel

A granular fuel and municipal waste technology, applied in the field of incinerators, can solve the problems of short service life of incinerators, difficult combustion air balance, difficult temperature control, etc., and achieve the effects of improving waste heat utilization, preventing heat loss, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

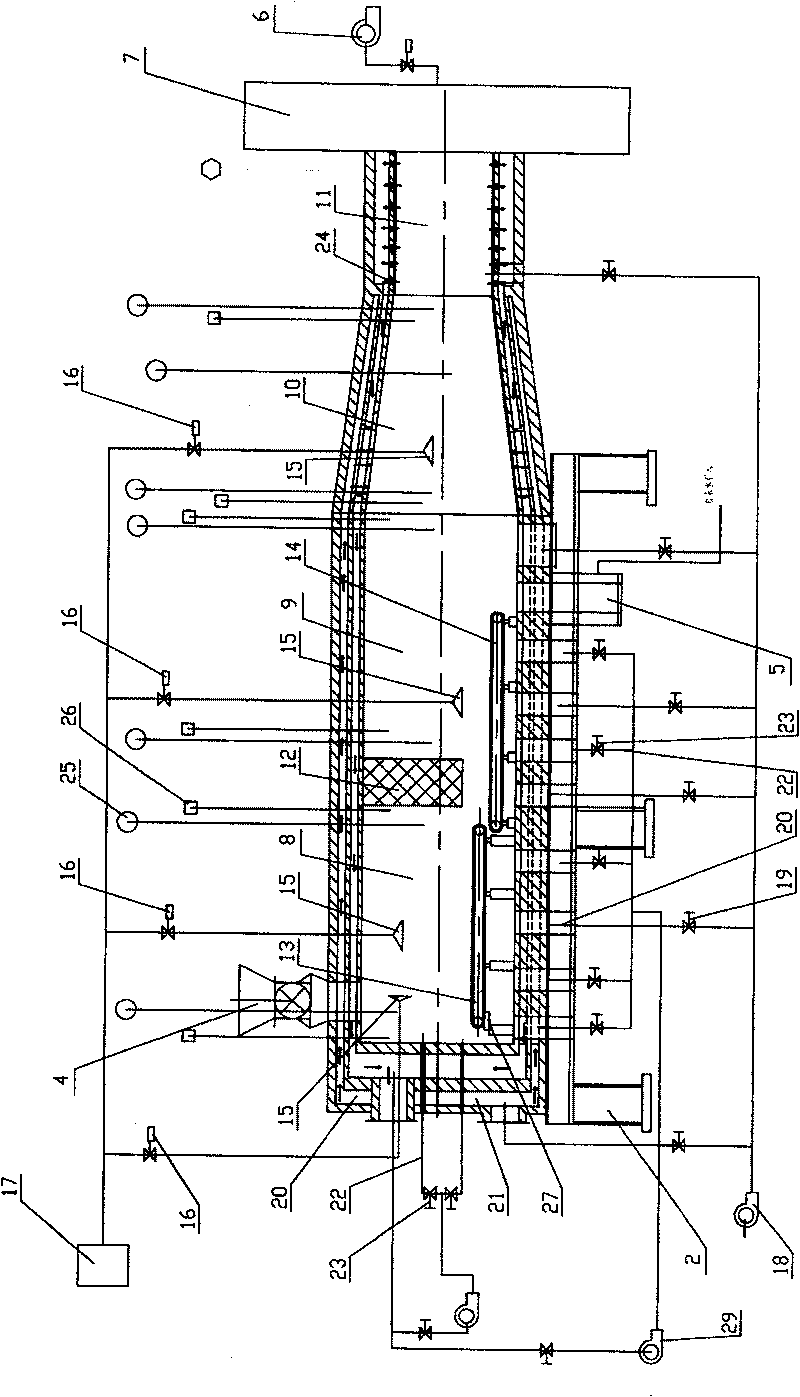

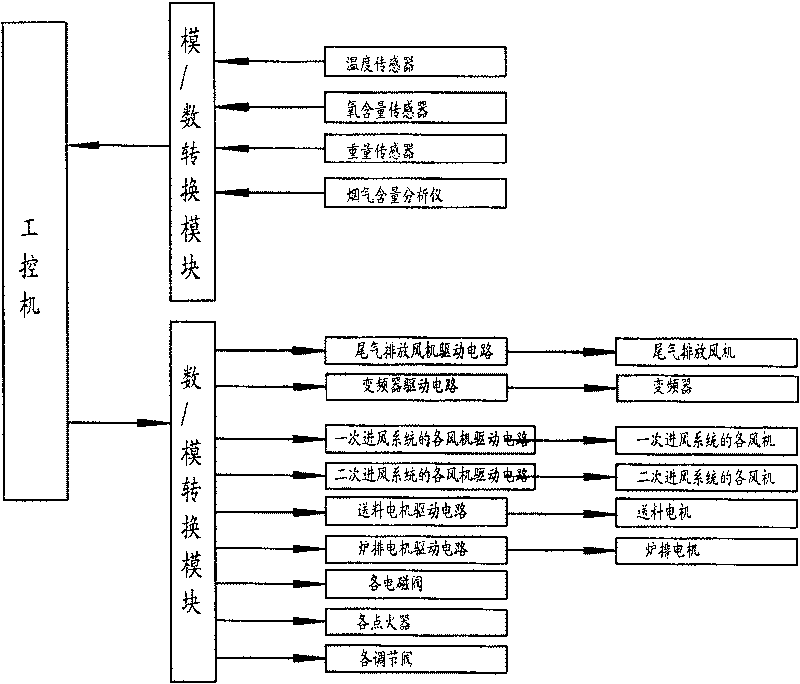

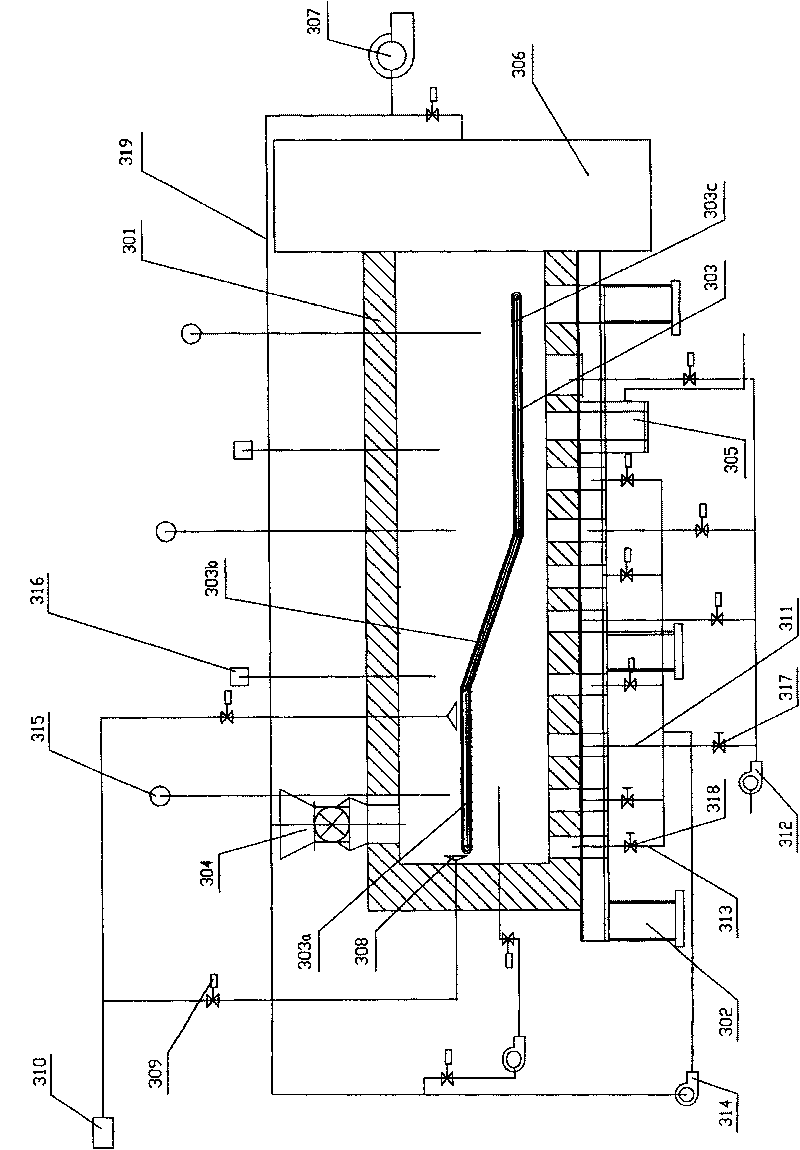

[0027] Depend on figure 1 As shown, the smart incinerator for municipal waste pellet fuel includes a furnace body 1, a base 2, a primary grate 13 with a drive motor (not shown) and a secondary grate 14, and a feed mechanism with a feed motor 4. Discharge port 5, ignition system, primary air intake system, secondary air intake system, automatic control system, waste heat boiler 7 with tail gas exhaust fan 6, the furnace body 1 is provided with first combustion chambers connected in sequence Chamber 8, the second combustion chamber 9, the third combustion chamber 10 and the air distribution chamber 11, the first and second combustion chambers are divided by the ceramic partition wall 12 in the body of furnace 1, and a The primary fire grate 13 and the secondary fire grate 14, the drive motors of the two fire grates are connected with the frequency converter (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com