Method and apparatus for recovering sulfer dioxide from smoke and producing thiamine fertilizer

A technology of sulfur dioxide and ammonium sulfate, applied in fertilization equipment, chemical instruments and methods, ammonium salt fertilizer, etc., can solve the problems of waste residue, poor development of ammonia method, and consumption of natural resources, so as to avoid secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

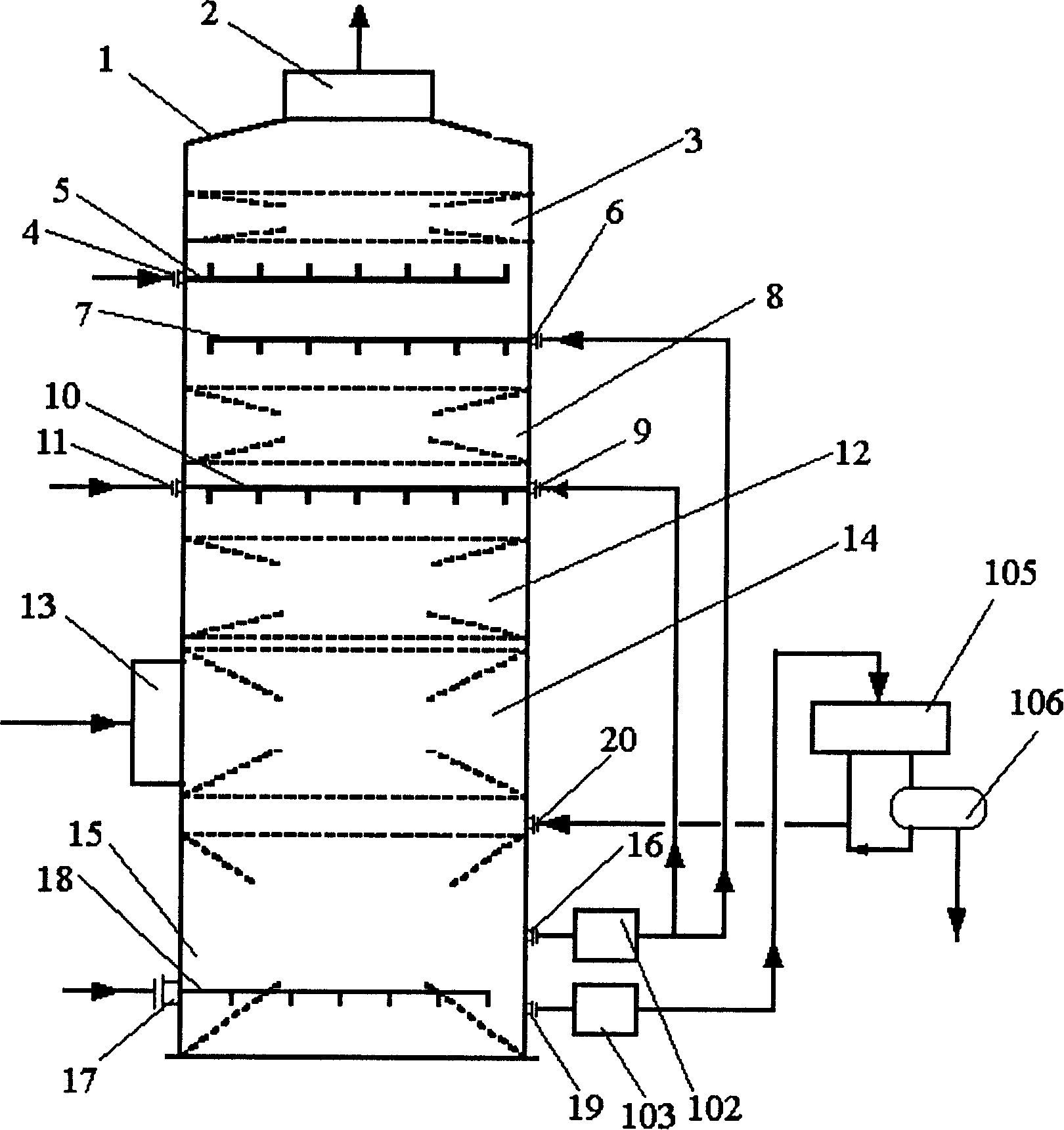

[0083] use figure 1 process and desulfurization crystallization tower.

[0084] A 260T / h thermoelectric boiler, burning coal with a sulfur content between 0.6-1.0%, and a flue gas flow rate of 340,000 Nm 3 / hr, SO 2 The content is 2000mg / Nm 3 , the dust content of flue gas is 80mg / Nm 3 , the flue gas temperature is 140°C.

[0085] The desulfurization crystallization tower 1 is cylindrical, and its structural parameters are as follows:

[0086] The desulfurization crystallization tower has a diameter of 7m and a height of 25m.

[0087] Plate corrugated packing is arranged in the defoaming area 3, and the packing height is 0.6m;

[0088] The process water distributor 5 is a nozzle distributor;

[0089] Ammonia recovery circulating fluid distributor 7 is a nozzle;

[0090] Ammonia recovery zone 8 is equipped with grid packing with a specific surface area of 90m 2 / m 3 , the packing height is 2m;

[0091] The sulfur dioxide absorbing liquid distributor 10 is a nozzle ...

Embodiment 2

[0105] Adopt the same method of embodiment 1, wherein:

[0106] 300,000 kW thermal power generation unit, burning coal with a sulfur content of 2.5%, and a flue gas flow rate of 1.1 million Nm 3 / hr, SO 2 The content is 6285mg / Nm 3 , the dust content of flue gas is 100mg / Nm 3 , the flue gas temperature is 145°C.

[0107] In this usage example, the desulfurization crystallization tower has a diameter of 12m and a height of 28m, the sulfur dioxide absorbing liquid distributor 10 is a nozzle with an aperture of 32mm, and there is no packing in the sulfur dioxide absorbing zone 12;

[0108] The temperature of the flue gas is 140°C, and it is directly sent from the outlet of the induced draft fan of the boiler to the inlet flue of the desulfurization crystallization tower. The inlet flue is equipped with a chilled spray pipe to pre-cool the flue gas to 90°C. After leaving the desulfurization crystallization tower, the SO in the tail gas 2 The content is 13mg / Nm 3 , NH 3 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com