Micromechanical thermalelectric-stack infrared detector compatible with co-complementive metal oxide semiconductor technology and preparing method

An infrared detector and thermopile technology, applied in the field of infrared detectors, can solve the problems of inability to obtain a large infrared absorption area, poor CMOS process compatibility, unfavorable device performance arraying, etc., to achieve good device performance and good compatibility , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

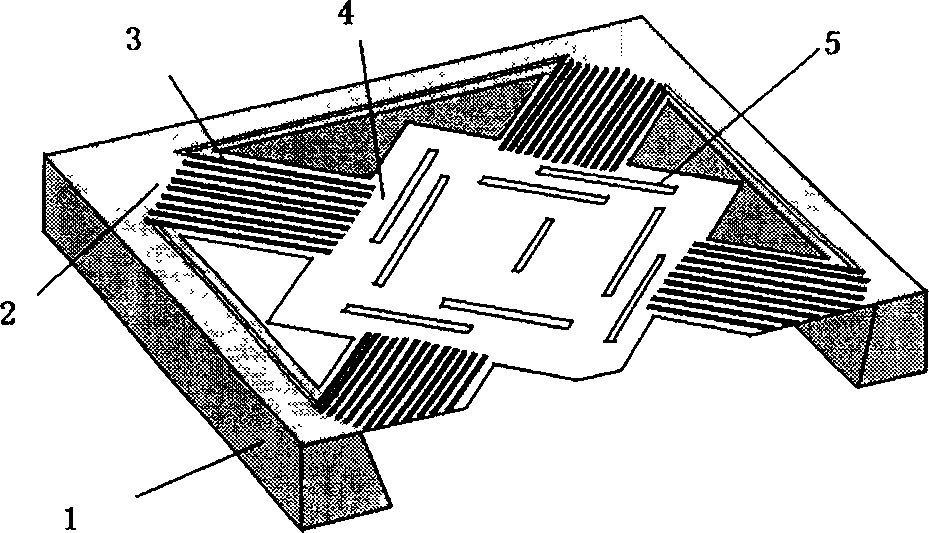

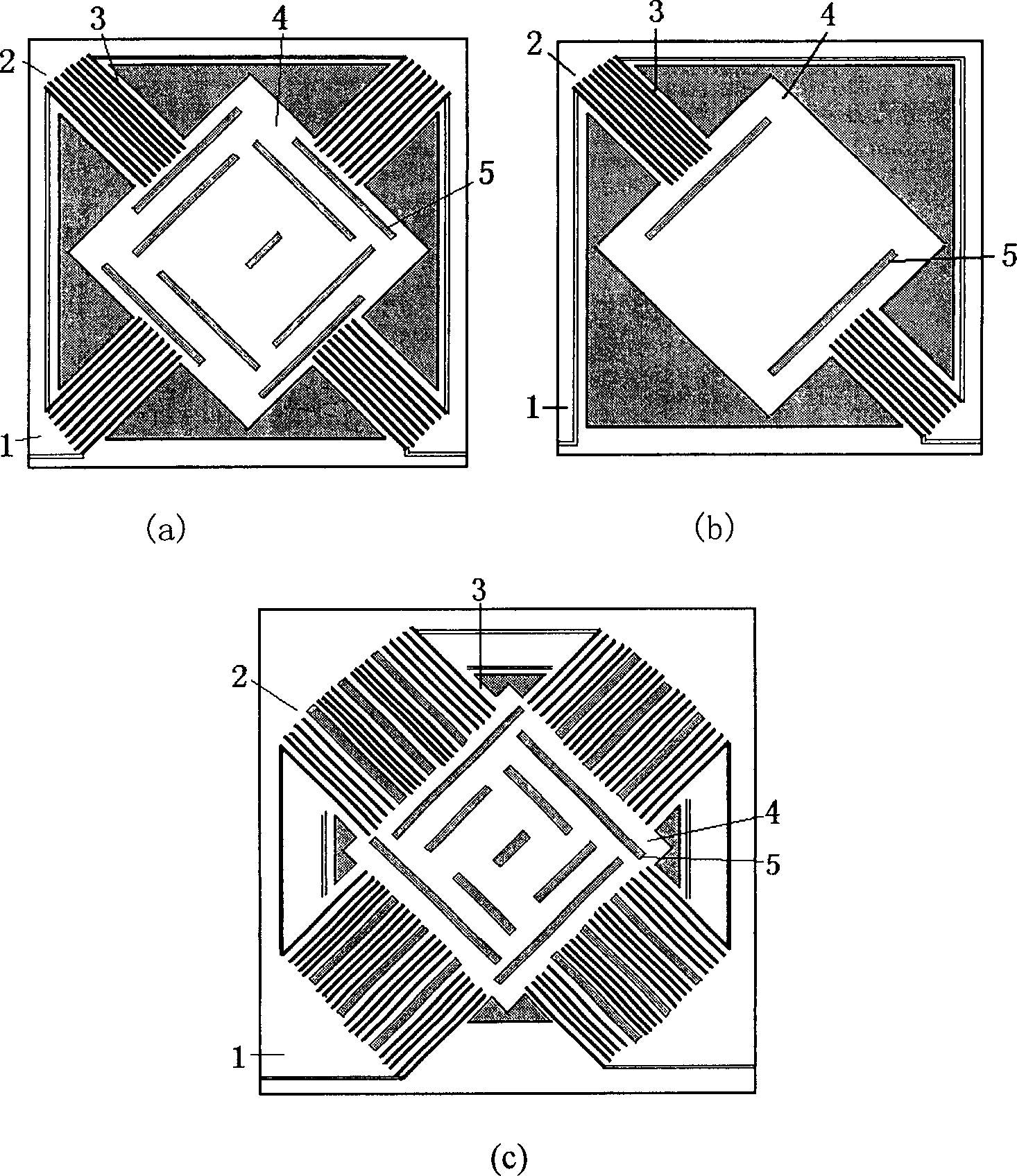

[0026] The structure of this embodiment can be found in figure 1 . Its production process is as follows:

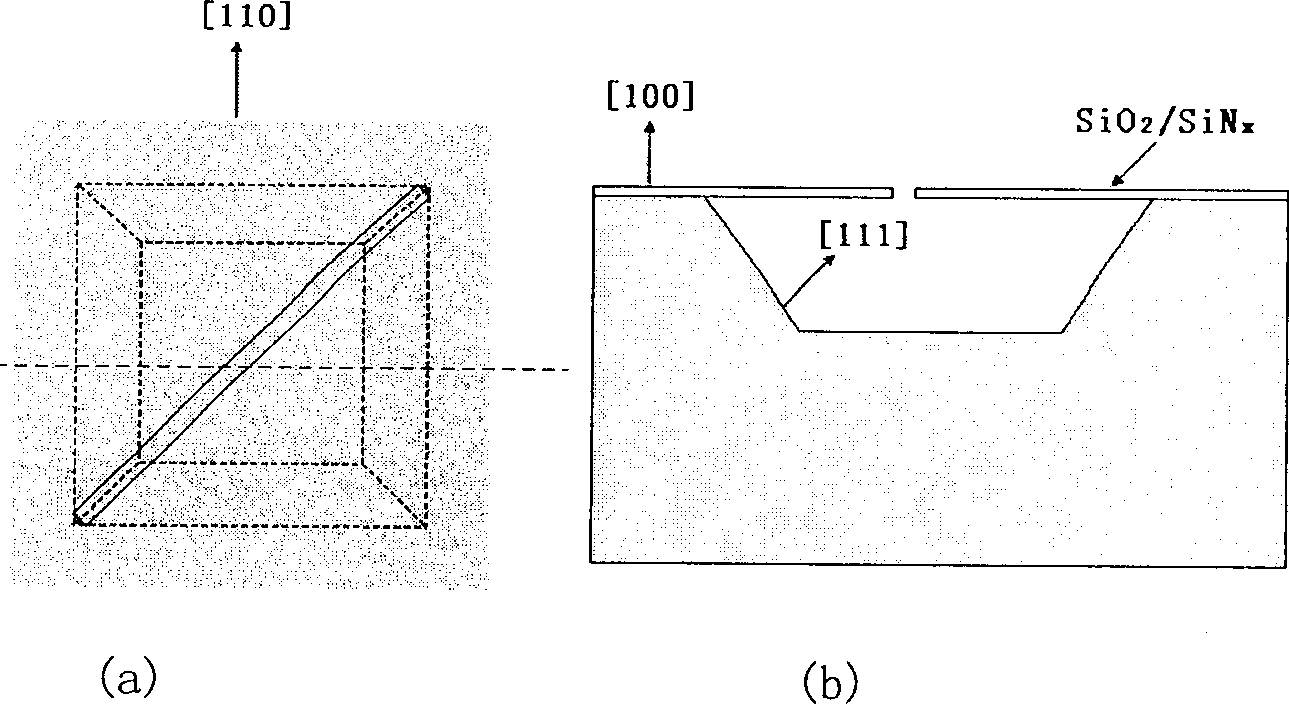

[0027] 1. Deposit a layer of SiO on (100) single crystal silicon by LPCVD 2 / Si 3 N 4 Double-layer dielectric film structure, the total film thickness is about 5000 Ȧ. Then grow a layer of polysilicon with a thickness of about 4000 Ȧ on it, and then grow about 1000 Ȧ of silicon oxide, such as Figure 5 - Shown in (a).

[0028] 2. After photolithography, BOE (Buffered Oxide Etch, buffered oxide etchant) and other processes are used to form silicon oxide window patterns on the surface, photoresist is used as an ion implantation mask layer, and P and B plasma are implanted into polysilicon to form polysilicon resistance strips. As a thermopile couple material such as Figure 5 -shown in (b).

[0029] 3. After photolithography harden the film, BOE wet-etches the silicon oxide on the surface of the remaining polysilicon, ion dry-etches the polysilicon outside the resis...

Embodiment 2

[0035] The top view of the structure of this embodiment can be found in figure 2 -(b), all the other are with embodiment 1.

Embodiment 3

[0037] The top view of the structure of this embodiment can be found in figure 2 -(c), all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com