Integrator system and method for rapidly determining effectiveness of a germicidal treatment

A technology of effectiveness and integrator, applied in the field of integrator system, can solve the problem that medical equipment is not an effective use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Results of hydrogen peroxide detection using an integrator containing arginine as an indicator chemical and using varying injection volumes

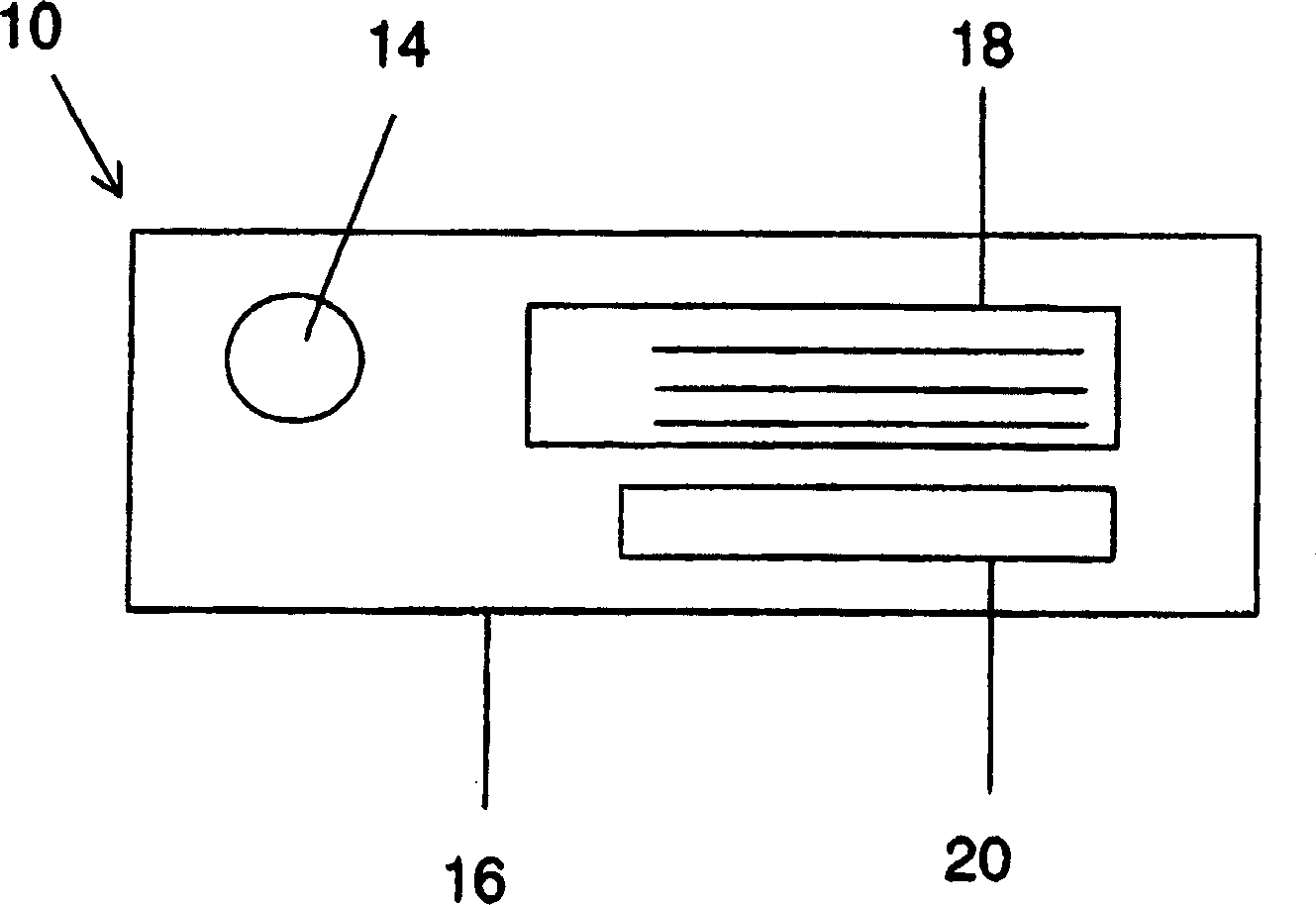

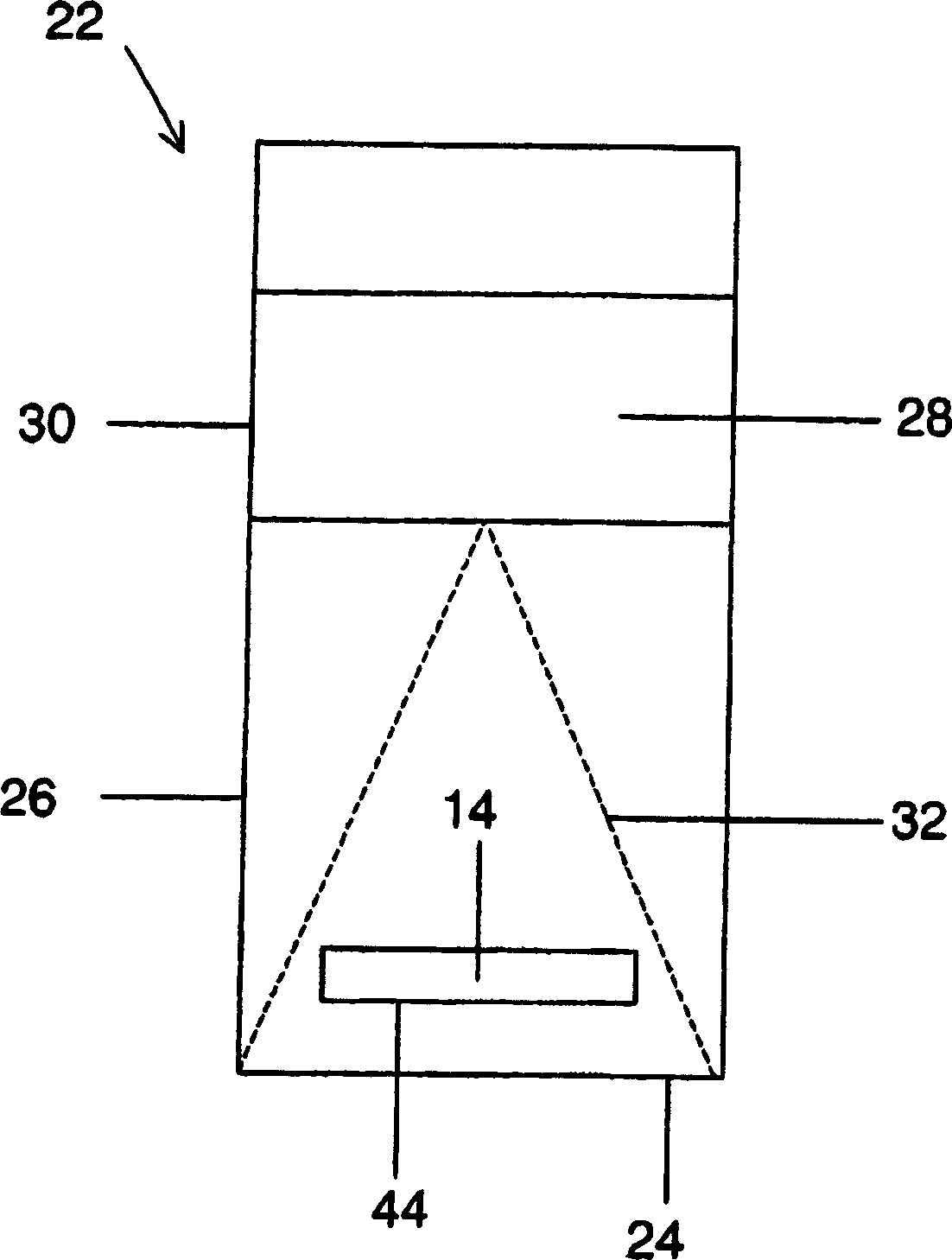

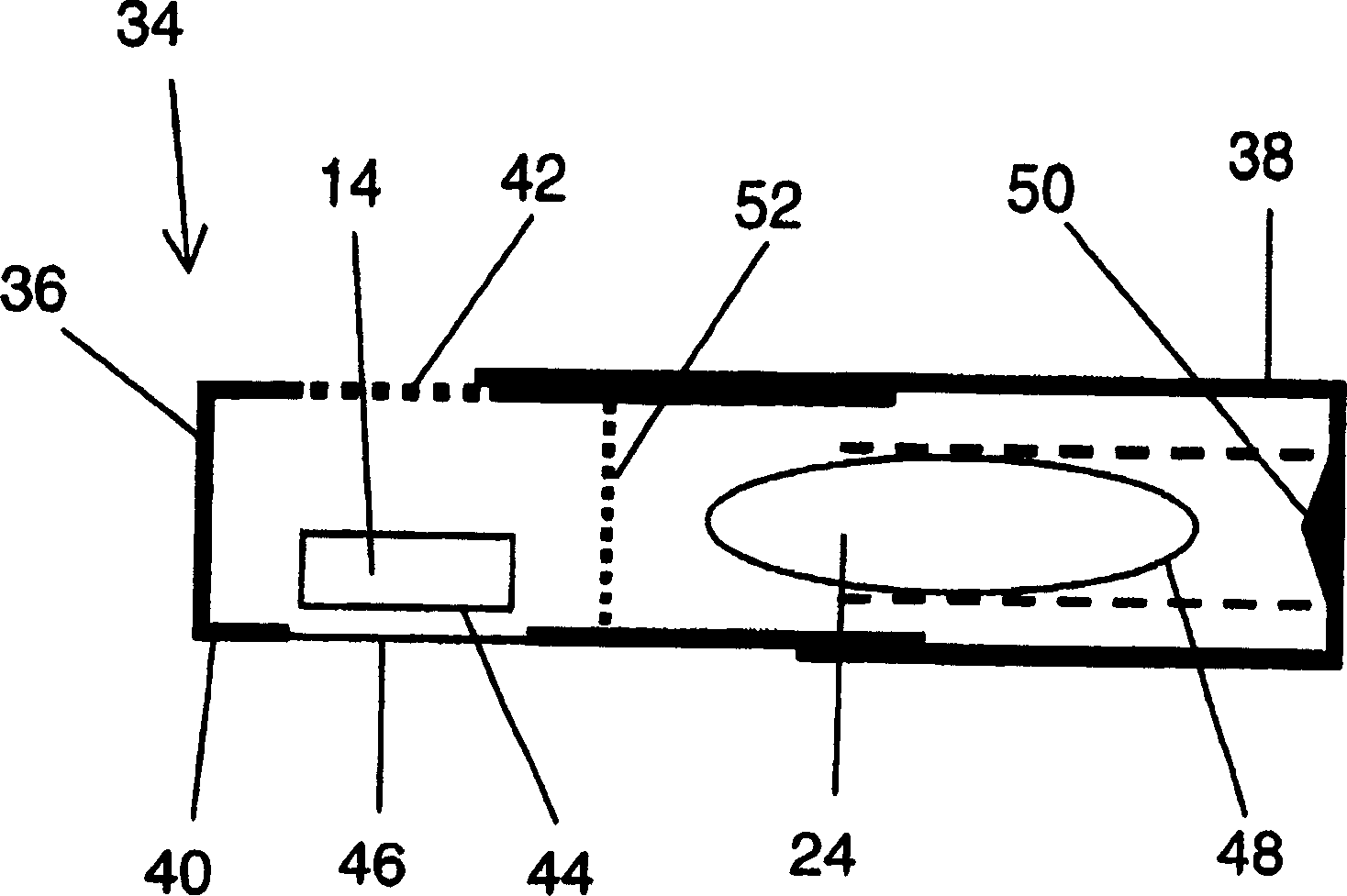

[0084] A series of integrators were prepared by contacting the paper disks with an aqueous solution of arginine. Place the integrator in the STERRAD with the instruments to be sterilized and some biological indicators 50 in the sterilizer. The paper disc is an absorbent substrate.

[0085] Vacuum the sterilizer to 0.8 torr. Plasma was generated in the chamber for 15 minutes to condition the load. The sterilizer was further evacuated to 0.4 torr and hydrogen peroxide was injected and left in contact with the load, integrator and biological indicator for 6 minutes.

[0086] Vent the sterilizer with air for 2 minutes. The sterilizer was again evacuated to 0.5 torr and the plasma was generated for an additional 2 minutes. The plasma power was 400 watts for both plasma exposures.

[0087] After the sterilization cycle, the pap...

Embodiment 2

[0095] Integrator response measured using a spectrophotometer

[0096] A non-absorbent fiberglass disc was impregnated with an aqueous solution of arginine. Fiberglass discs are non-absorbent substrates. Place the disc in the STERRAD 50 sterilizer, and the same conditions as in Example 1 were used for the treatment with varying injection volumes of hydrogen peroxide. The amount of hydrogen peroxide is shown in Table 2 below.

[0097]After the cycle is complete, contact the glass fiber disc with 50 μL of a 5% solution of OPA dye precursor in water. The optical absorption intensity of the disk was determined at about 470 nm, about 550 nm and about 610 nm (red, green and blue wavelengths) using a TAOS TCS230EVM evaluation module color sensor (Parallax, Rocklin, California).

[0098] Injection volumes of 50, 300, and 1000 μL of hydrogen peroxide were employed. at STERRAD All BIs were negative when 300 μL of hydrogen peroxide was injected in a 50 sterilizer. Table 2 summ...

Embodiment 3

[0104] Integrator detection using histidine as indicator chemical and OPA as dye precursor

[0105] A series of integrators were formed in Example 3 using histidine instead of arginine as the primary amine indicator chemical. An aqueous histidine solution was placed on a series of fiberglass discs to form an integrator according to an alternative embodiment of the invention.

[0106] Place the integrator on a standard STERRAD 50 payload items, cycling was performed as described in Examples 1 and 2.

[0107] Cycle with 0 μL hydrogen peroxide and 300 μL hydrogen peroxide. At the end of the sterilization process, contact the integrator with 50 μL of 5 vol % OPA solution. The intensity of the third color of the third compound on the integrator was determined using the TAOS color sensor described in Example 2. A combination of red, green, and blue (RGB) wavelengths (470, 550, and 610 nm) was used to measure the response, since the reaction product of histidine with OPA is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com