Modified adsorbent for oil component in water, its production and adsorber

An adsorbent and water adsorption technology, which is applied in the direction of adsorption water/sewage treatment, separation methods, chemical instruments and methods, etc., can solve the problems of lower concentration, weak affinity of emulsified oil beads, etc., and achieve low oil concentration in effluent and high adsorption speed Fast, high adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following performance tests of the examples, imported oily sewage with an oil content of 70mg / l and a water temperature of 20°C was used. The test of the oil content in the water carried out the UV spectrophotometry in the "Water and Wastewater Monitoring and Analysis Method" compiled by the State Environmental Protection Administration. Law.

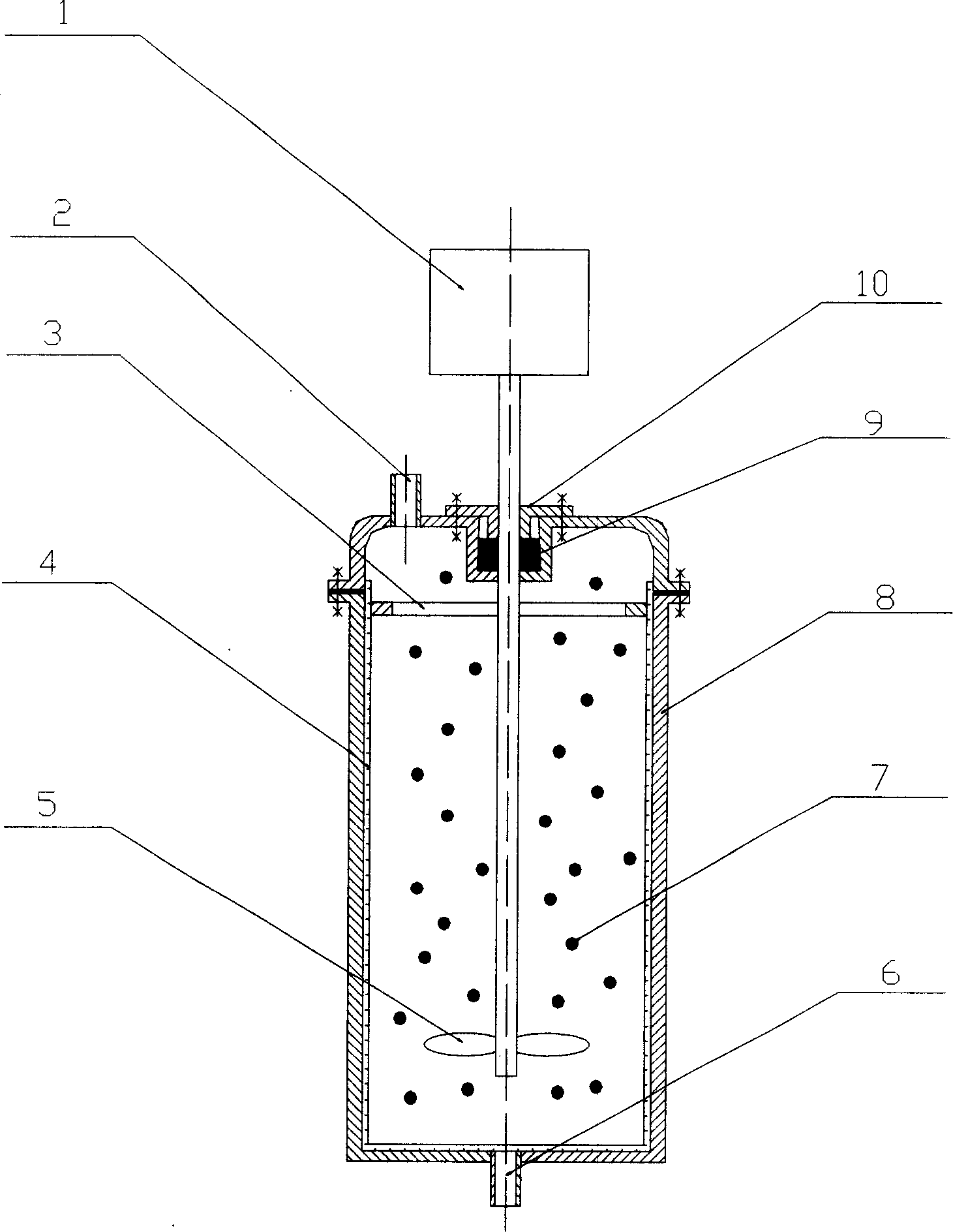

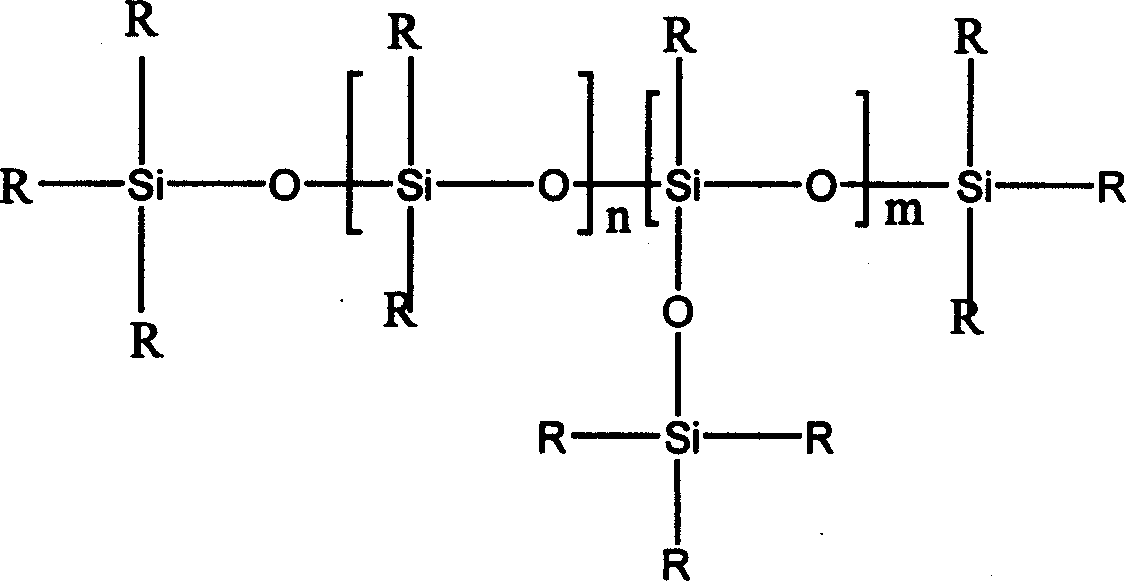

[0023] 1. First prepare 1000g of simethicone emulsion with a mass concentration of 0.01%, then mix 999.9g of diatomaceous earth and simethicone emulsion in a container, and stir thoroughly. Put the mixture in a tray, spread it out, put it into an oven, and bake it at 50°C for 24 hours. After drying, take it out, break up the agglomerates, and pass through a 40-mesh sieve to obtain a powdery modified diatomite adsorbent. Using this adsorption device for two-stage series test, the results are shown in the table.

[0024] 2. First prepare 1000 g of simethicone emulsion with a mass concentration of 10%, then mix 900 g of dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com