Process for preparing quick response temperature sensitive water gel

A temperature-sensitive hydrogel and fast-response technology, applied in the field of functional polymers, can solve the problems of high performance requirements of pore-forming agents, difficulty in controlling the reaction process, and difficulty in controlling the heterogeneous structure, so as to improve the deswelling power Chemical performance, fast dehydration performance, easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 1 g of ethanethiol in 20 g of 1,4-dioxane solution, then add 3 g of N-isopropylacrylamide, 0.13 g of N, N-methylenebisacrylamide, azobisisobutyl Nitrile 1g. Put the above raw materials into the reactor, evacuate to remove oxygen, then fill with nitrogen and seal, react at 40°C for 6 hours to obtain a gel; then soak the obtained gel in deionized water at room temperature for 2 days, Change the water once a day to remove the residual monomers and cross-linking agents in the gel to obtain the desired temperature-sensitive hydrogel.

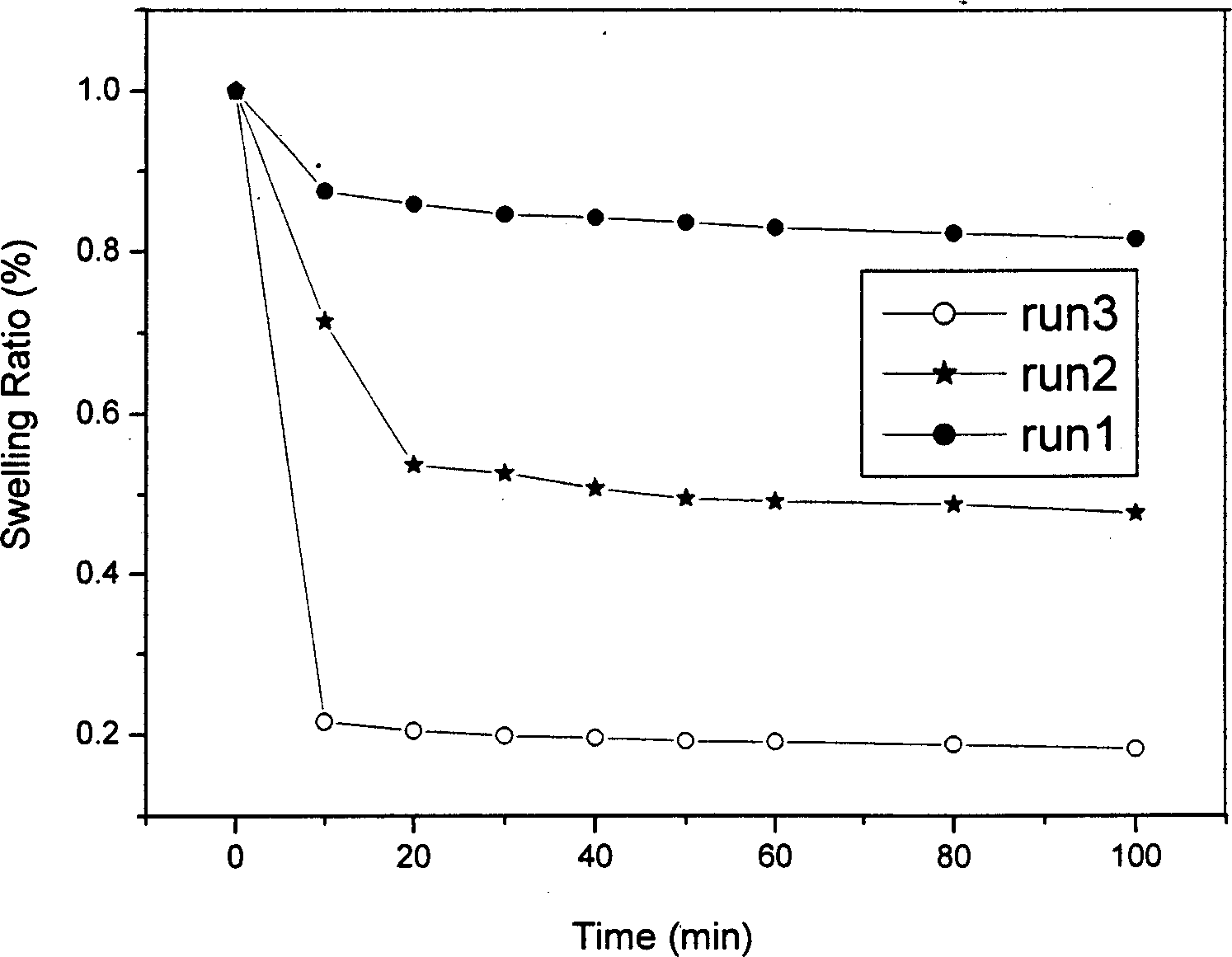

[0022] The deswelling kinetics of the hydrogel was measured gravimetrically, and the hydrogel showed accelerated deswelling kinetics.

Embodiment 2

[0024] Dissolve 0.5g of dodecanethiol in 20g of 1,4-dioxane solution, then add 2g of N-isopropylacrylamide, 1g of N,N-methylenebisacrylamide, azobisiso Butyronitrile 0.5g. Put the above raw materials into the reactor, vacuum to remove oxygen, then fill with nitrogen and seal, react at 80°C for 48 hours to obtain a gel; then soak the obtained gel in deionized water at room temperature for 8 days, Change the water once a day to remove the residual monomers and cross-linking agents in the gel to obtain the desired temperature-sensitive hydrogel.

[0025] The deswelling kinetics of the hydrogel was measured gravimetrically, and the hydrogel showed accelerated deswelling kinetics.

Embodiment 3

[0027] First dissolve 0.1g of dithiobenzoic acid in 20g of 1,4-dioxane solution, then add 7g of N-isopropylacrylamide, 2g of N,N-methylenebisacrylamide, azobis Isobutyronitrile 0.04g. Put the above raw materials into the reactor, evacuate to remove oxygen, then fill with nitrogen and seal, react at 55°C for 16 hours to obtain a gel; then soak the obtained gel in deionized water for 4 days at room temperature, Change the water once a day to remove the residual monomers and cross-linking agents in the gel to obtain the desired temperature-sensitive hydrogel.

[0028] The deswelling kinetics of the hydrogel was measured gravimetrically, and the hydrogel showed accelerated deswelling kinetics.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap