Fabrication method

A technology of imprinting and liquid layer, applied in the field of forming conductive structures in substrates, can solve problems such as difficulty in arranging resists

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

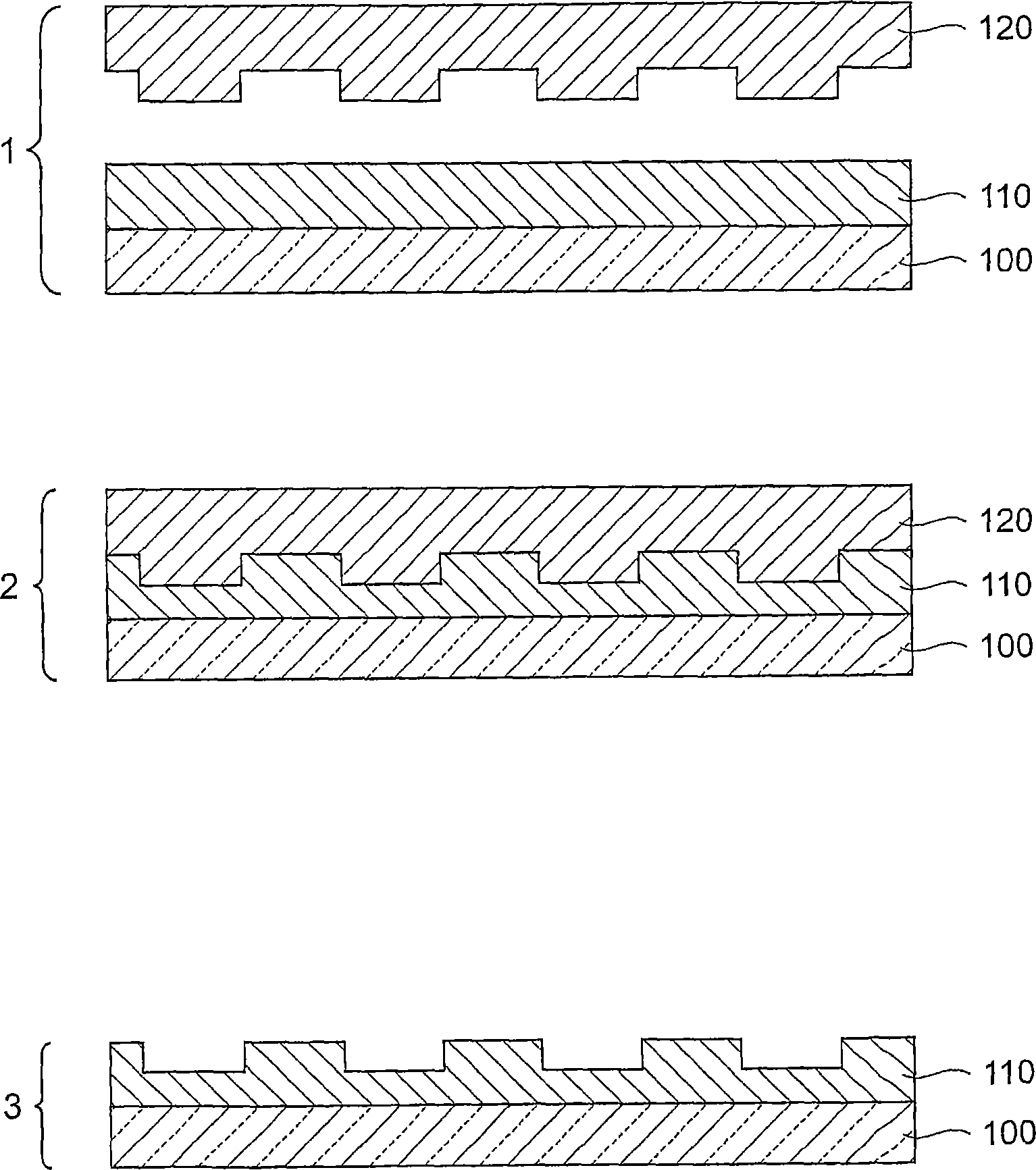

Image

Examples

Embodiment Construction

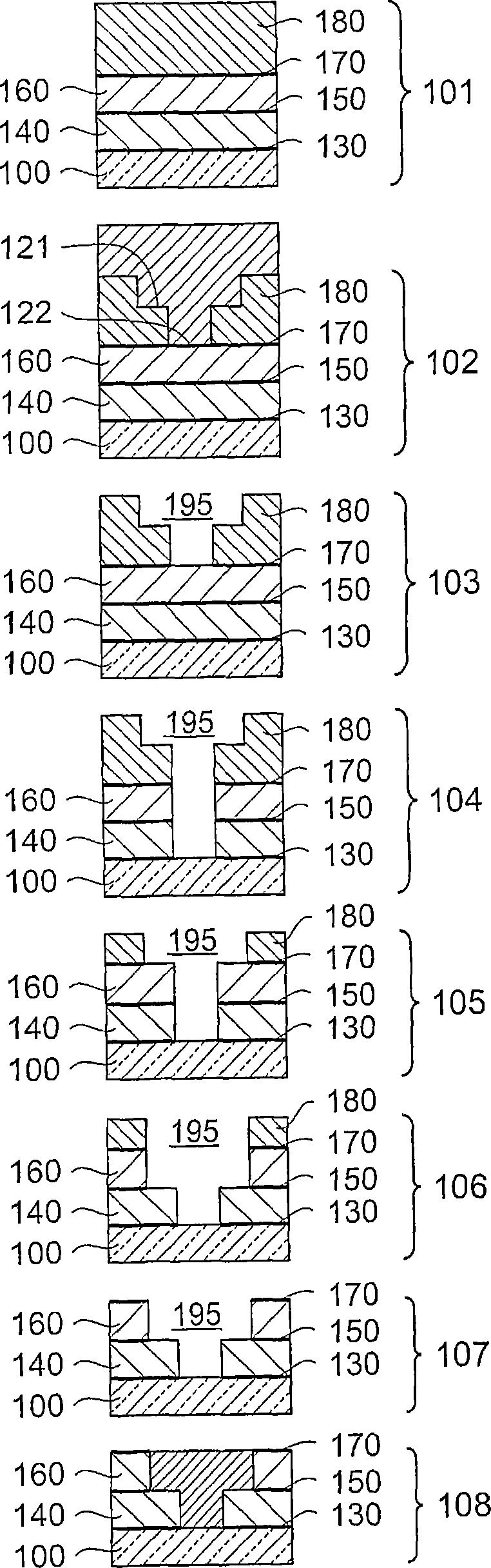

[0019] refer to figure 2 , in one embodiment of the present invention, in step 101 , a diffusion barrier layer 130 is deposited on the substrate 100 . Diffusion barrier layer 130 covers both the dielectric and previously fabricated vias or wiring connections for connection to subsequent attach layers of the device. A first homogeneous dielectric layer 140 is deposited on the diffusion barrier layer 130 . A uniform silicon nitride etch stop layer 150 is deposited on the first dielectric layer 140 . A second uniform dielectric layer 160 is deposited on the etch stop layer 150 . A silicon nitride hard cap layer 170 is deposited on the second dielectric layer 160 . A uniform liquid pre-polymer resist layer 180 is deposited on the hard coat layer 170 . Dielectric layers 140 and 160 may be formed from the SiLK material available from the Dow Chemical Company described above. Deposition of the resist layer 180 can be done by sputter coating, spin coating, pipetting or by a roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com