A plate type biofiltration tower and waste gas treatment process thereof

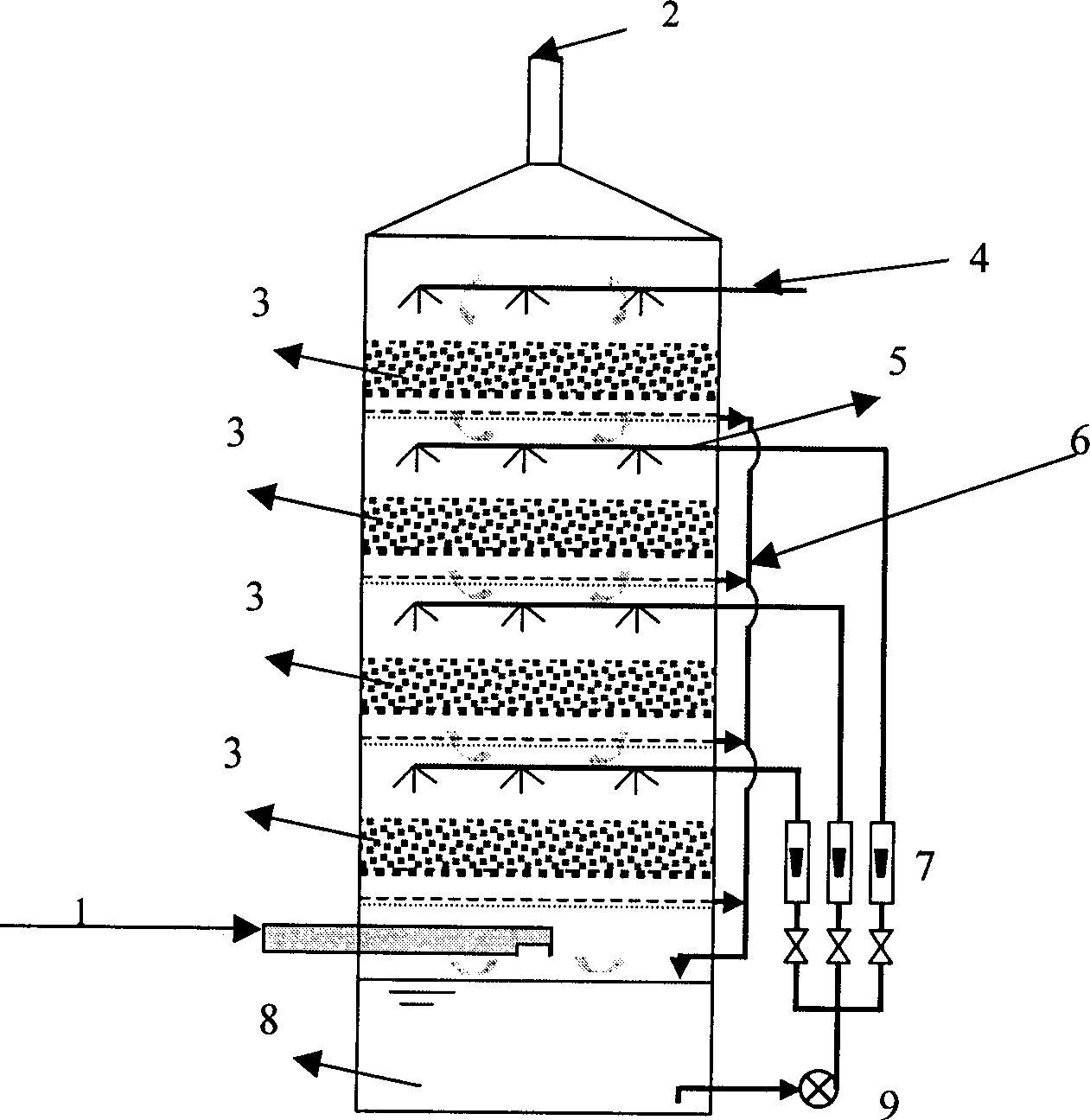

A filter tower and biological technology, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as uneven distribution of water and biomass, easy blockage of pipeline dehydrators, and low support strength, etc., to achieve Avoid channeling, reduce strength requirements, and facilitate packing replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

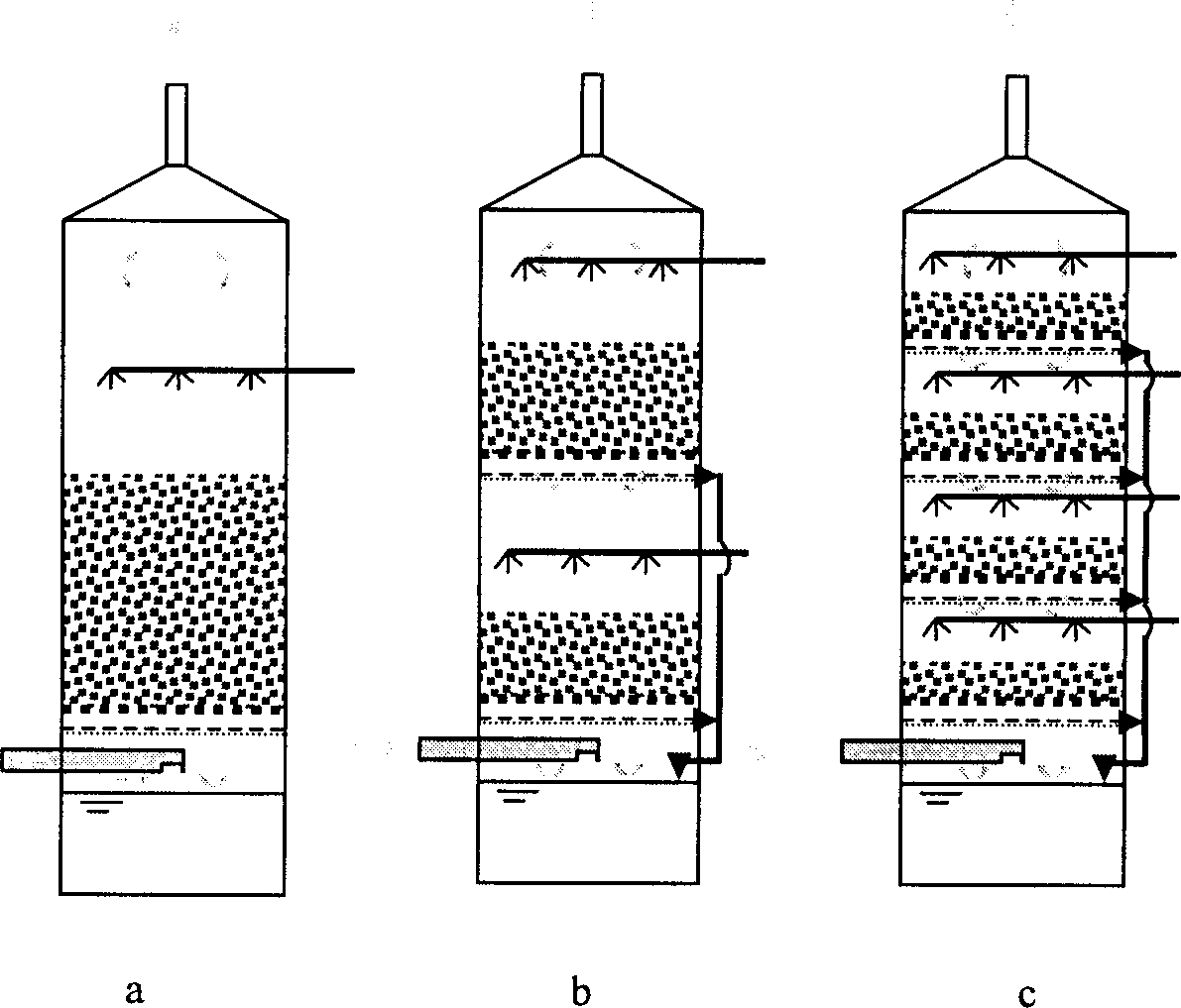

Embodiment 1

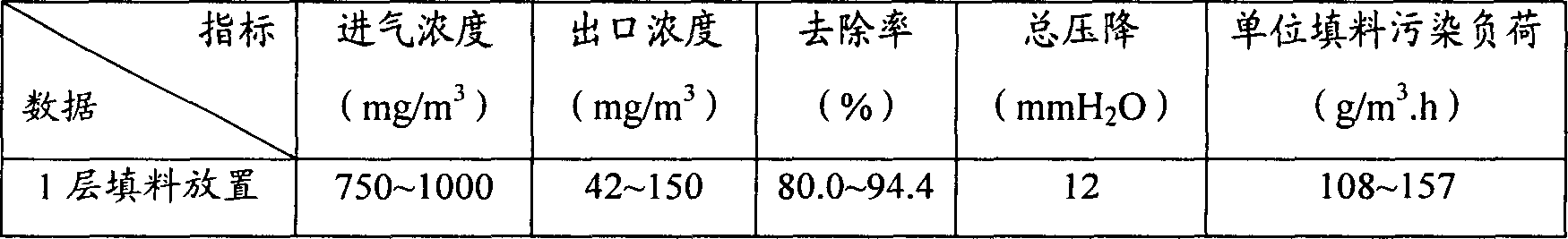

[0023] Embodiment and working principle of the present invention are: containing toluene 0.75~1.00g / m 3 Plate-type biological filtration treatment process of waste gas, empty bed gas velocity 0.05m / s, empty bed residence time 20s, packing layer temperature 25-30°C, liquid phase pH range 6.5-7.5 (microbial dominant bacteria are Pseudomonas spp. The biofilm carrier filler is a plastic flat triangle). The inner diameter of the tower is 800mm, and the biofilm carrier filler is placed in three ways: one layer (thickness 1.0m), two layers (each thickness 500mm), and four layers (thickness each 250mm). Nutrients and toluene exhaust gas are in reverse contact, and nutrients are sprayed The strength control is the same, that is, 20L / m 2 .h, such as figure 2 shown. The exhaust gas treatment results are shown in Table 1.

[0024] Table 1 Toluene waste gas treatment results

[0025]

[0026] (875)

[0027] The results in Table 1 show that under ...

Embodiment 2

[0029] Embodiment and working principle of the present invention are: containing H 2 S 0.175~0.228g / m 3Plate-type biological filtration treatment process for waste gas, empty bed gas velocity 0.05m / s, empty bed residence time 20s, packing layer temperature 25-30°C, liquid phase pH range 3.0-4.0 (microbial dominant bacteria are Thiobacillus genus, biological Membrane carrier packing is plastic flat triangle). The inner diameter of the tower is 800mm, and the biofilm carrier filler is still placed in three ways: one layer (thickness 1.0m), two layers (each thickness 500mm), and four layers (thickness each 250mm). 2 S exhaust gas reverse contact, nutrient spray intensity control is the same, that is, 20L / m 2 .h, such as figure 2 shown. The exhaust gas treatment results are shown in Table 2.

[0030] Table 2H 2 S waste gas treatment result

[0031]

[0032] The results in Table 2 show that under the same operating conditions, the structure of the plat...

Embodiment 3

[0034] The embodiment and working principle of the present invention are as follows: the operating conditions are the same as in Example 1, the inner diameter of the tower is 800 mm, and there are four layers of biofilm carrier packing trays, each layer thickness is 250 mm, and the nutrient spray is controlled by three modes: Mode 1 , the spray intensity of the four layers is the same, both are 20L / m 2 .h; mode 2, the top tray is not sprayed, and the spray intensity of the other three layers is the same, that is, 20L / m 2 .h; mode 3, the top tray is not sprayed, and the other three layers start from the inlet end of the bottom layer, and the spray intensity is gradually reduced by 30%, that is, the bottom layer is 20L / m 2 .h, second floor 14L / m 2 .h, three layers 9.8L / m 2 .h. The exhaust gas treatment results are shown in Table 3.

[0035] Table 3 Toluene waste gas treatment results

[0036]

[0037] The results in Table 3 show that the exhaust gas bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com