N alpha-Boc-N beta-Cbz-L-2,3 diaminopropionic acid derivative synthesis method

The technology of a diaminopropionic acid and a synthesis method is applied in the field of synthesis of Nα-Boc-Nβ-Cbz-L-2, 3-diaminopropionic acid derivatives, which can solve the problems of low yield and high cost, and achieve the goal of producing The effect of high yield, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

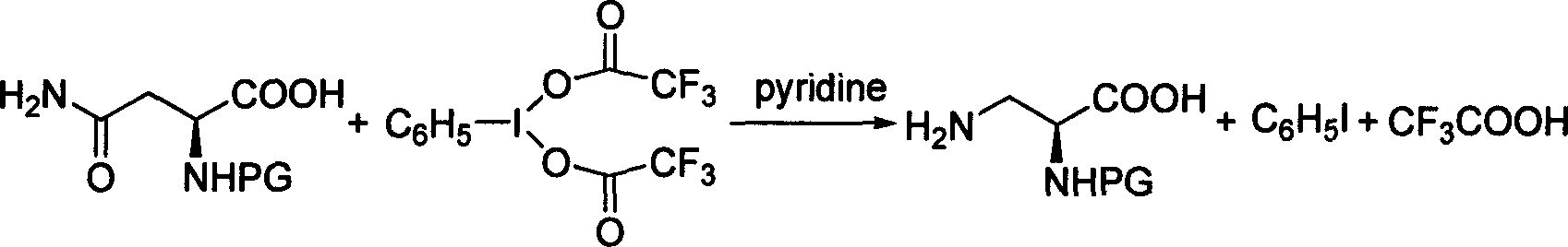

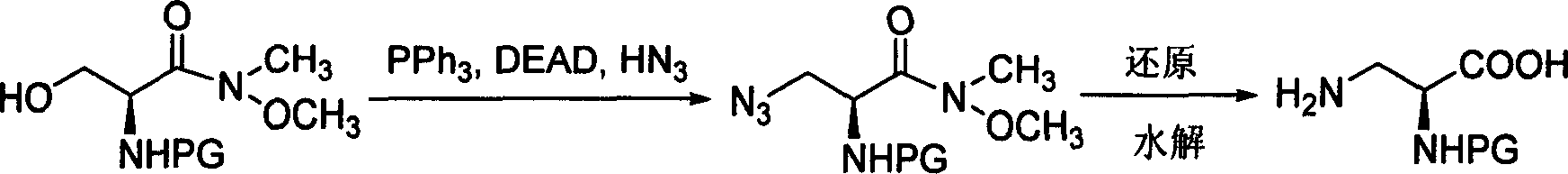

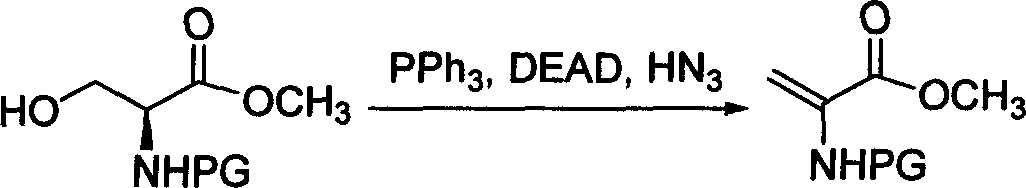

Method used

Image

Examples

Embodiment 1

[0035] Synthesis of Example 1 Compound 7

[0036] N-Boc-L-aspartic acid (25 mmol) was dissolved in 10 mL of ethyl acetate, and 200 mL of benzene was added. After heating to about 60°C, paraformaldehyde (50 mmol) and a catalytic amount of p-toluenesulfonic acid (1.5 mmol) were added. Install an oil-water separator, and after reflux for 2 hours, add 100 mL of ethyl acetate to the reaction solution, and then use 0.3M K 2 CO 3 (2.5mL), washed with saturated brine (2×10mL), anhydrous Na 2 SO 4 Let dry overnight. After filtration, the solvent was distilled off under reduced pressure to obtain 74.4 g of a slightly yellow solid (Compound 7), with a yield of 72%. m.p. = 132-134°C; [α] 20 D +153.1 (c=1, CH 3 OH); 1 HNMR (300MHz, CDCl 3 ): δ=1.49(s, 9H), 3.03-3.27(m, 2H), 4.31(s, 1H), 5.24(d, 2H, J=3), 5.45(br, 1H). 13 CNMR (75MHz, CDCl 3 ): δ=28.59, 34.70, 51.68, 78.84, 82.92, 152.24, 172.12, 175.26. MS: m / z=284 [M+K]+ .Anal.Calcd for C 10 h 15 NO 6 : C, 48.98; H, 6.17; N...

Embodiment 2

[0037] The synthesis of embodiment two compound 8

[0038] Compound 7 (10mmol) was dissolved in anhydrous THF (30mL), cooled in an ice-salt bath to below -15°C, after adding EtOCOCl (11mmol), N-methylmorpholine (NMM) (12mmol) was added, and a white precipitation. At this temperature, after stirring the mixture for 20 minutes, the NaN 3 (25mmol) aqueous solution (5mL) was added to the reaction solution, and stirring was continued at about -10°C for 1h. Stop the reaction, add a small amount of water to dissolve the insoluble matter, transfer it to a separatory funnel, extract once with ethyl acetate 150mL, wash with saturated brine (2×10mL), anhydrous Na 2 SO 4 Let dry overnight. After filtration, the solvent was evaporated under reduced pressure to obtain a slightly yellow liquid (note: compounds containing azide are explosive and cannot be evaporated to dryness). Transfer this crude product to a silica gel column, use petroleum ether / ethyl acetate (2:1, v / v) as eluent, co...

Embodiment 3

[0039] Synthesis of Embodiment Three Compound 9

[0040] Dissolve the compound 8 obtained in Example 2 in toluene (30 mL), install a spherical condenser, seal it with oil, and heat it to 75°C under stirring until no gas is generated (about 2h), evaporate the solvent under reduced pressure, and obtain a colorless thick product liquid compound 9. This compound was used immediately in the next reaction without further purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com