Multi-channel output DC-DC inverter

A DC converter and multi-output technology, applied in the direction of output power conversion device, conversion equipment with intermediate conversion to AC, DC power input conversion to DC power output, etc., to achieve enhanced EMC performance, easy implementation, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

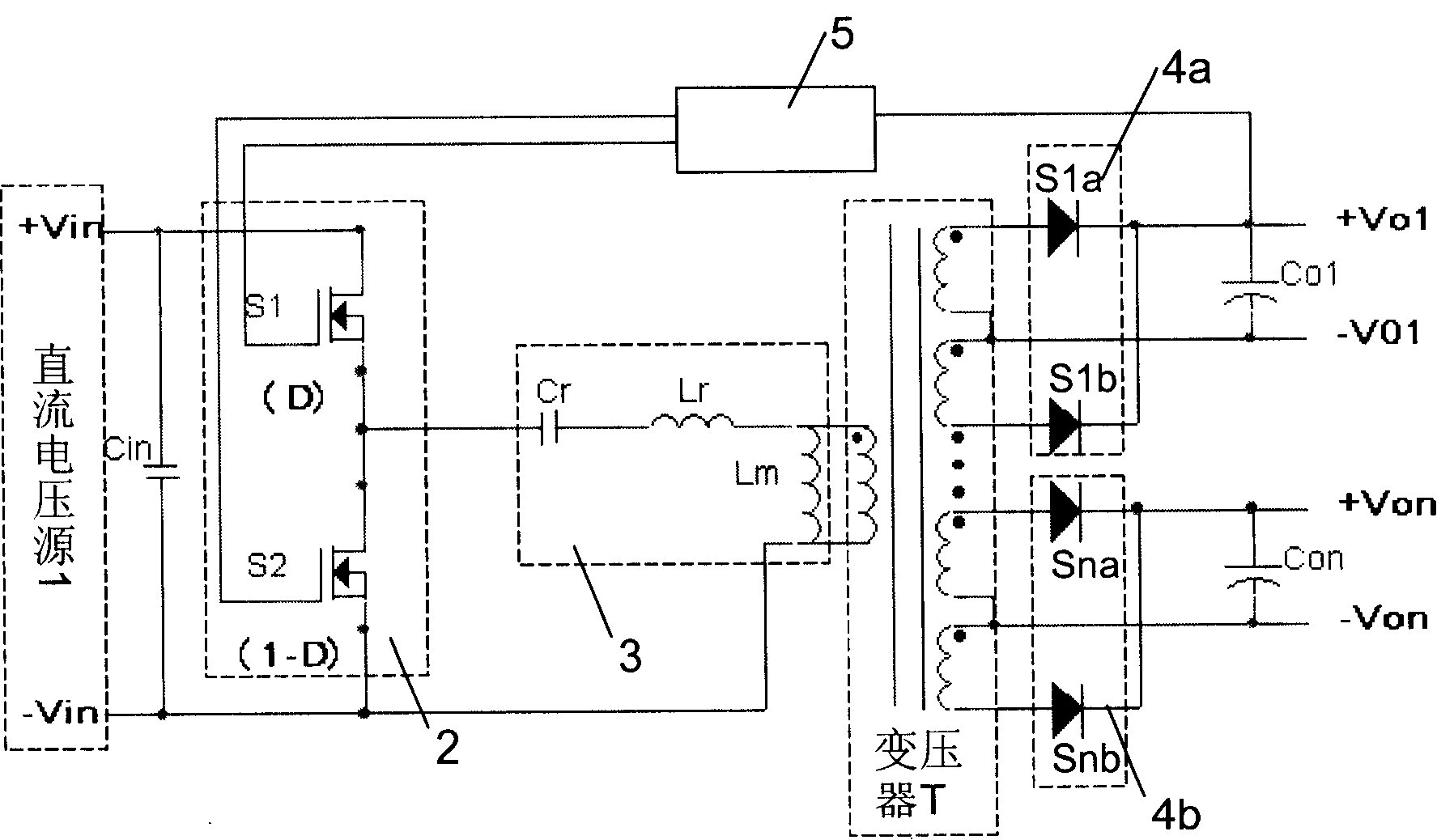

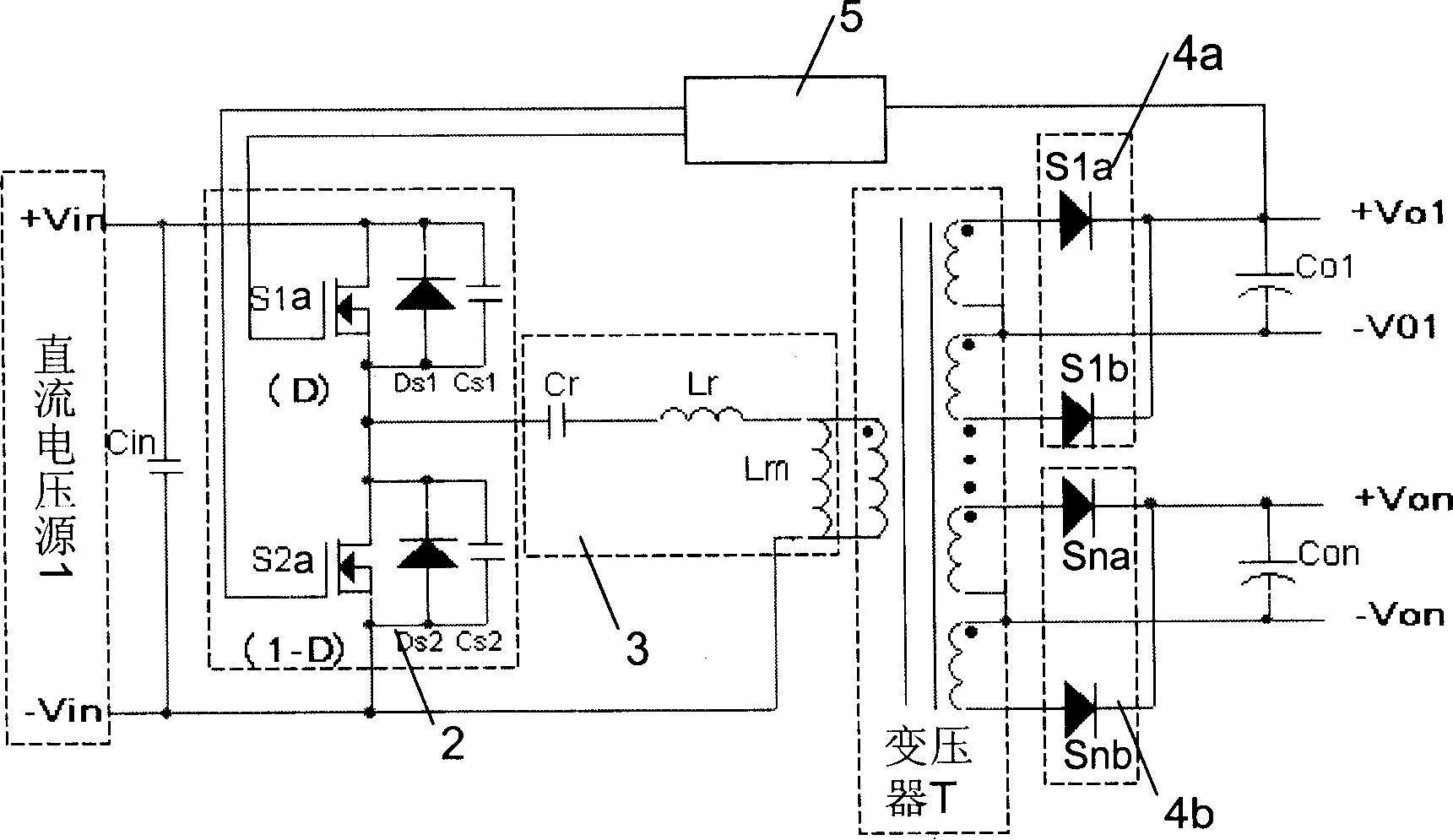

[0036] The PWM control circuit 5 respectively outputs a square wave with a duty ratio of D, a switching frequency of fs and a square wave with a duty ratio of 1-D to the chopper 2 . The PWM control circuit 5 includes a drive circuit, a PWM modulation circuit, an isolation circuit, a PID (proportional, integral, differential control) regulator, and a reference voltage circuit.

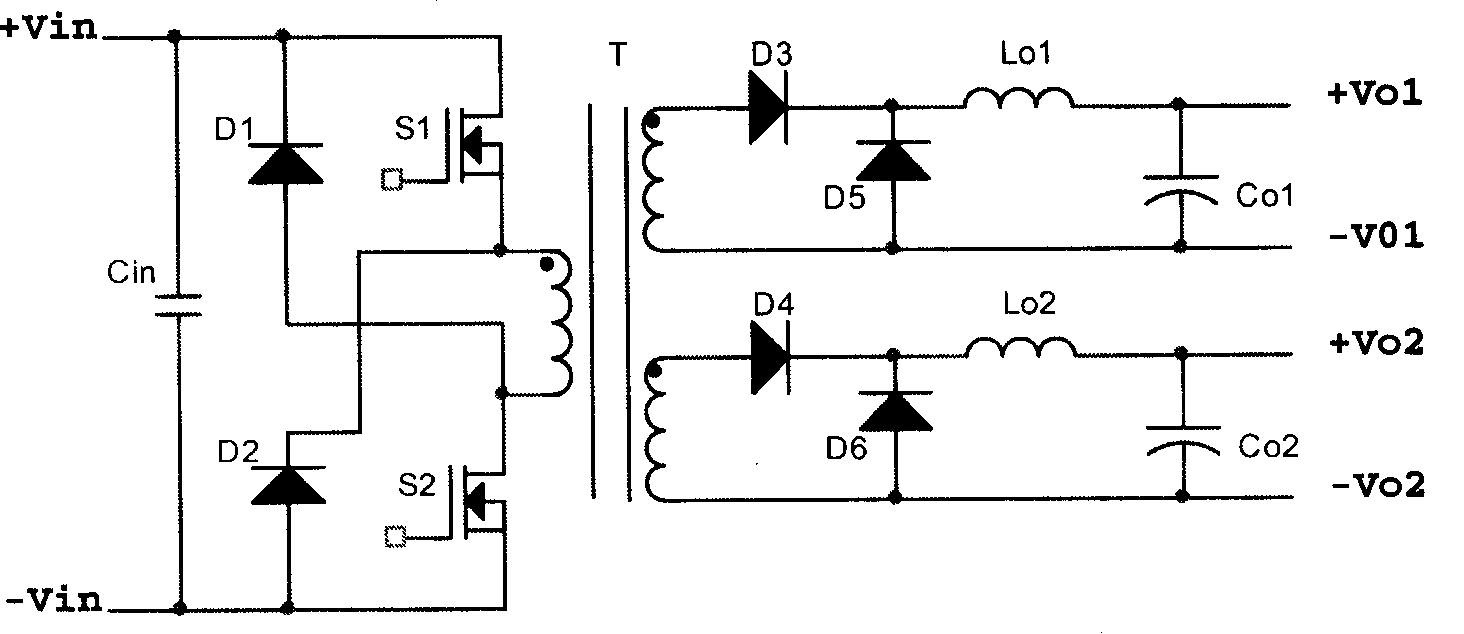

[0037] The chopper 2 is composed of the first switching tube S1 and the second switching tube S2 in series, the chopper 2 is connected in parallel with the above-mentioned DC voltage source 1, and the PWM control circuit outputs a square wave with a duty ratio of D to the first switching tube The input of S1 outputs a square wave with a duty ratio of 1-D to the input of the second switching tube S2, and the chopper 2 can chop the DC power into an AC square wave and output it to the resonant circuit 3 .

[0038] The resonant circuit 3 is composed of a resonant capacitor Cr, a first resonant inductance Lr...

specific Embodiment approach 2

[0090] like Figure 8 As shown, the fourth embodiment differs from the first embodiment in that the auxiliary rectification circuit is a voltage doubler rectification circuit for the auxiliary circuit. The transformer T is composed of n+2 ((n>0, n is a natural number)) windings, and a voltage doubler filter Con' is added to each auxiliary circuit. The n+2 winding on the secondary side of the transformer T is connected to the nth output rectifier tubes Sna and Snb, and the nth output rectifier tubes Sna and Snb are rectified and then connected to the nth output filters Con and Con'. The output filter Cona and the series doubler filter Con' are connected in parallel to the output terminal Von.

specific Embodiment approach 3

[0091] like Figure 9 As shown, the difference between this specific embodiment and the first specific embodiment is that: the post-regulation scheme of the auxiliary circuit is adopted, so as to stabilize the output voltage of the auxiliary circuit. Each auxiliary road in this specific embodiment is added with a control switch Snc and an auxiliary road control circuit 9 (Control). The auxiliary circuit control circuit 9 inputs the output voltage of the auxiliary circuit, and the output terminal of the auxiliary circuit control circuit 9 is connected with the control terminal of the control switch. The nth rectifier tubes Sna and Snb are rectified and then connected to the control switch Snc, and the control switch Snc is then connected to the nth output filter Con. The switching tube Snc is controlled by the auxiliary circuit control circuit 9, and the auxiliary circuit control circuit 9 adjusts the output signal according to the nth output voltage to control the control swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com