Crystallization technique in engineering of producing crystalline dextrose

A technology for crystallization of glucose and crystallization, applied in the field of glucose production technology, can solve the problems of long crystallization cycle, large amount of mother liquor, low utilization rate, low production yield, etc., and achieves improvement of quality and yield, saving manpower and material resources, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The starch milk is liquefied, saccharified, filtered, decolorized and evaporated to a dry matter of 73%.

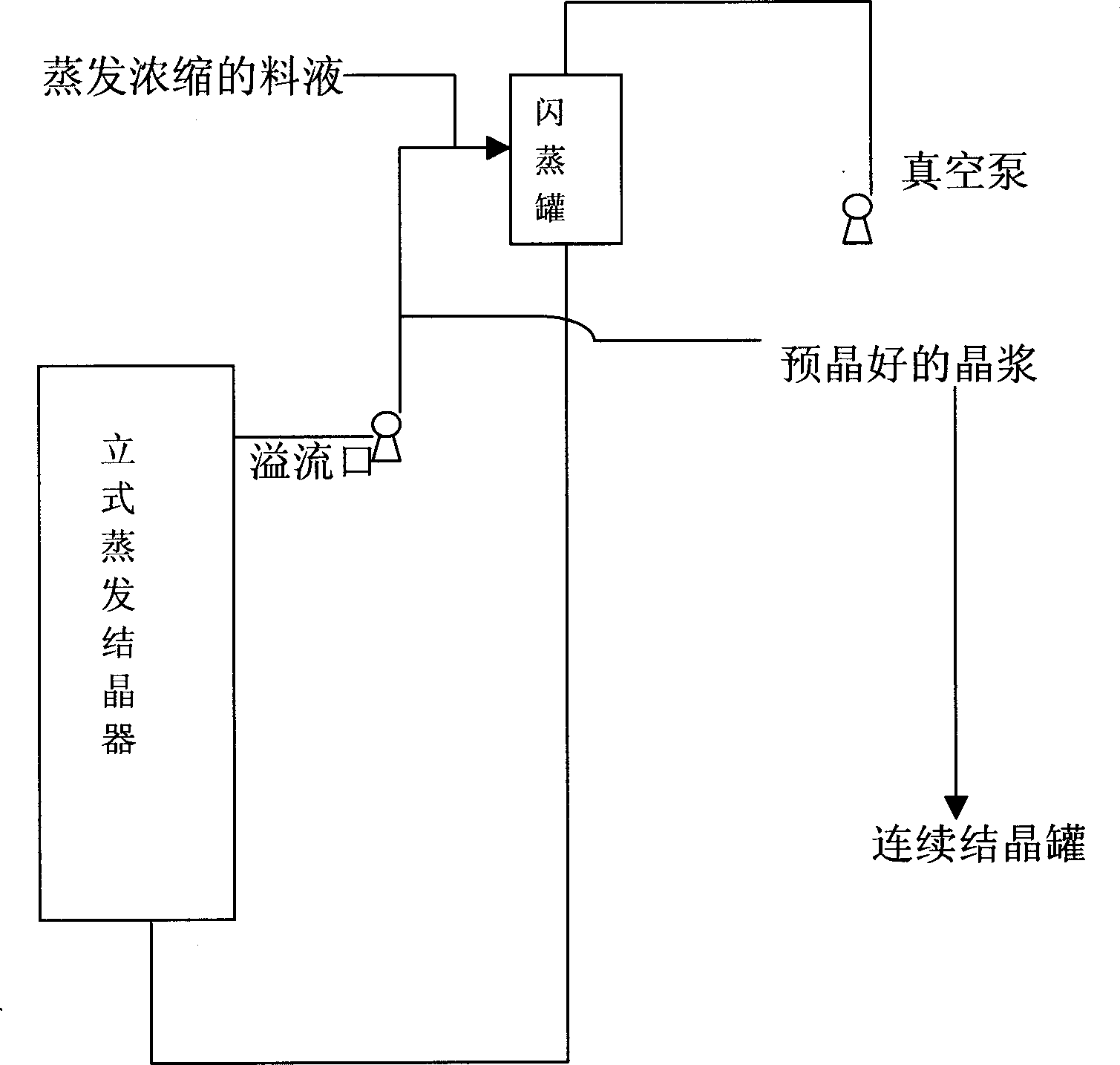

[0028] (2) The above-mentioned concentrated solution is poured into the flash tank for vacuum concentration and evaporation until the dry matter is 77.5%, and then circulated into the 260m 3 After 30 hours of pre-crystallization in the vertical evaporative crystallizer, 7m 3 Carry out crystallization in the primary crystallizer among the four-stage crystallizers. The remainder is recycled to the flash tank.

[0029] (3) After the pre-crystallization, the pre-crystallized crystal slurry is driven into the four-stage continuous crystallization tank (25m 3 ) crystallization, can increase the production of 56 tons of crystallized glucose per day.

Embodiment 2

[0031] (1) The starch milk is liquefied, saccharified, filtered, decolorized, evaporated and concentrated until the dry matter is 70%.

[0032] (2) The above-mentioned concentrated solution is poured into the flash tank for vacuum concentration and evaporation until the dry matter is 78%, and then circulated for 260m 3 After 25 hours of pre-crystallization in the vertical evaporative crystallizer, 8m 3 Carry out crystallization in the primary crystallizer among the four-stage crystallizers. The remainder is recycled to the flash tank.

[0033] (3) After the pre-crystallization, the pre-crystallized crystal slurry is driven into the four-stage continuous crystallization tank (25m 3 ) crystallization, can increase the production of 58 tons of crystalline glucose per day.

Embodiment 3

[0035] (1) The starch milk is liquefied, saccharified, filtered, decolorized and evaporated to a dry matter of 71%.

[0036] (2) The above-mentioned concentrated solution is poured into the flash tank for vacuum concentration and evaporation until the dry matter is 78%, and then circulated for 260m 3 After 20 hours of pre-crystallization in the vertical evaporative crystallizer, 6m 3 Crystallize in the primary crystallizer in the four-stage continuous crystallizer. The remainder is recycled to the flash tank.

[0037] (3) After the pre-crystallization, the pre-crystallized crystal slurry is driven into the four-stage continuous crystallization tank (25m 3 ) crystallization, can increase the production of 55 tons of crystalline glucose per day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com