Method for preparing milk beverage

A technology for milk beverages and products, applied in dairy products, milk preparations, applications, etc., can solve the problems that granular raw materials cannot pass, limit product raw material selection, equipment damage, etc., achieve considerable economic benefits, expand raw material selection, avoid The effect of particle destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the formulated yoghurt drink that is rich in pulp particles

[0038] Formula (according to 1 ton):

[0039] Milk 350.0 kg White sugar: 60.0 kg Acesulfame potassium: 0.2 kg Sodium carboxymethyl cellulose: 3.6 kg Citric acid: 2.4 kg Lactic acid: 1.8 kg Yellow peach pulp granules: 60.0 kg Peach flavor: 0.4 kg Purified water: 521.6 kg

[0040] Raw material standards:

[0041] Yellow peach granules: size 3×3×3mm, pH: 3.8, sugar content: 30BX, fruit content: 61.0%;

[0042] Other raw and auxiliary materials meet the relevant national standards.

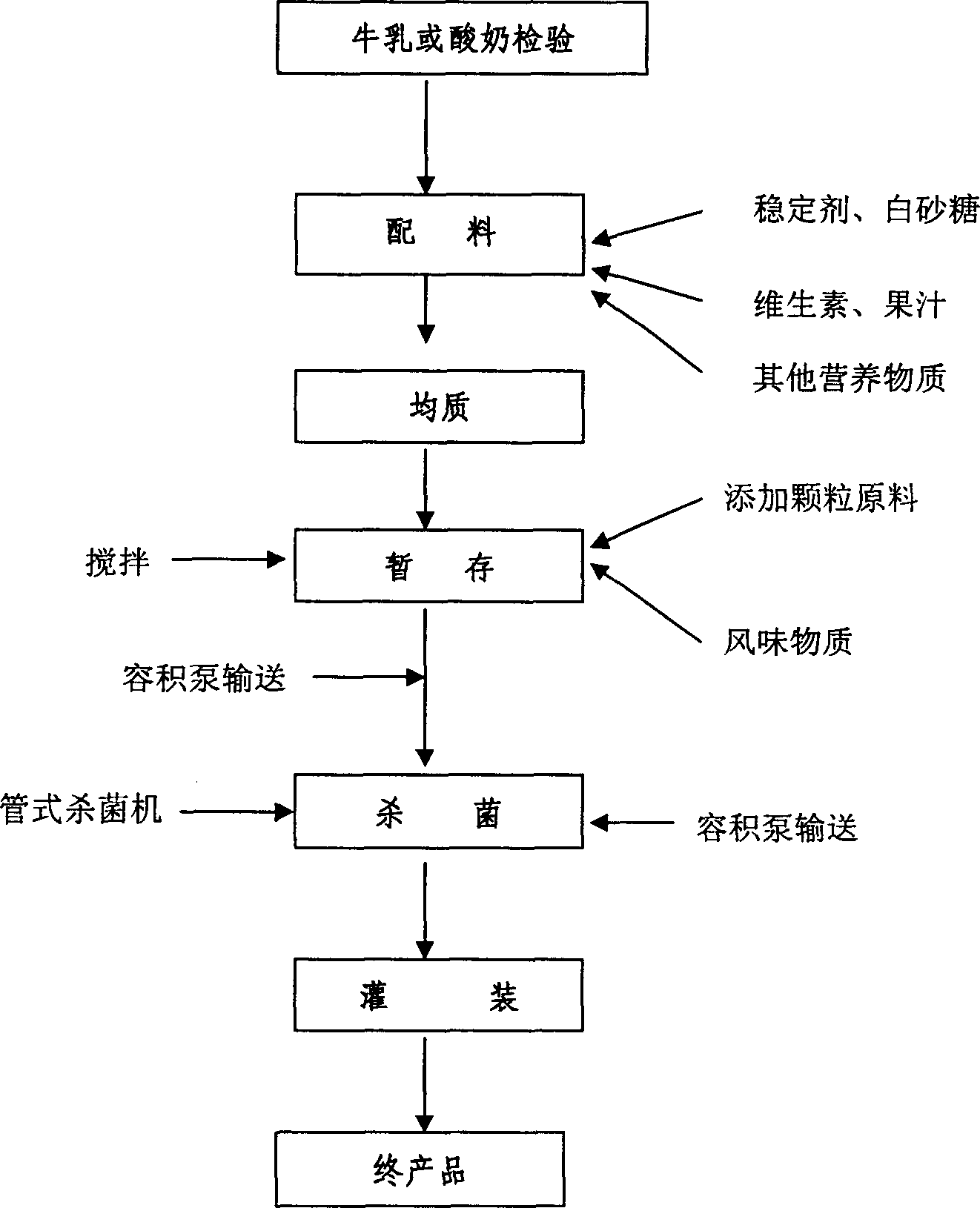

[0043] The process flow chart of the production process is as follows figure 1 As shown, the specific process is as follows:

[0044] 1 Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators, which meet the relevant national standards.

[0045] 2. Ingredients:

[0046] a. Dissolution of thickener: sodium carboxymethylcellulose: ...

Embodiment 2

[0065] Embodiment 2, the lactic acid bacteria drink that is rich in coconut fruit pulp

[0066] Formula (according to 1 ton):

[0067] Yogurt: 400.0 kg White sugar: 40.0 kg High fructose syrup (70.0%): 60.0 kg Coconut: 55.0 kg Pectin: 3.6 kg Citric acid: 1.5 kg Yogurt essence: 0.3 kg Purified water: 439.6 kg

[0068] Raw material standard:

[0069] The size of coconut fruit is 3×4×4mm, pH: 4.5, sugar content: 15BX, fruit content: 70.0%;

[0070] Other raw and auxiliary materials meet the relevant national standards.

[0071] Preparation Process:

[0072] 1. Preparation of yoghurt: use Hansen YM-381 strain for fermentation, and the acidity (titration acidity) of yoghurt reaches 80. After T, it is rapidly cooled to below 10°C, and the acidity of the yogurt is controlled within the range of 80--90°T.

[0073] 2. Preparation of lactic acid bacteria beverage: it can be produced according to conventional production methods, stored in buffer tanks, and flavored.

[0074] 3. Add...

Embodiment 3

[0087] Embodiment 3 contains the yoghurt drink of modified starch granules

[0088] Formula (according to 1 ton):

[0089] Milk: 450.0 kg White sugar: 45.0 kg Neotame: 0.0075 kg Modified starch granules: 5.0 kg Pectin: 3.0 kg Propylene glycol alginate: 1.0 kg Lactic acid: 2.0 kg Citric acid: 2.5 kg Yogurt essence: 0.5 kg Purified water: 491.0 kilogram.

[0090] Raw material standard:

[0091] Modified starch granule diameter 1.5mm;

[0092] Other raw and auxiliary materials meet the relevant national standards.

[0093] Preparation Process:

[0094] 1. Prepare the yogurt drink according to the conventional production method and store it in the buffer tank.

[0095] 2. Add starch granules: Slowly add starch granules to the buffer tank

[0096] The buffer tank is provided with an agitator, the impeller of which is a 3-leaf open turbine (θ=24°), the rotating speed is 1200rpm, and the outer diameter of the blade is 0.5 times the diameter of the container. When the feed liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com