Composition for paper feed roll manufacture, paper feed roll and method of manufacture thereof

A manufacturing method and technology of paper feed rollers, applied in roads, instruments, traffic signals, etc., can solve problems such as mutual adhesion, and achieve the effects of excellent productivity, high compatibility, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

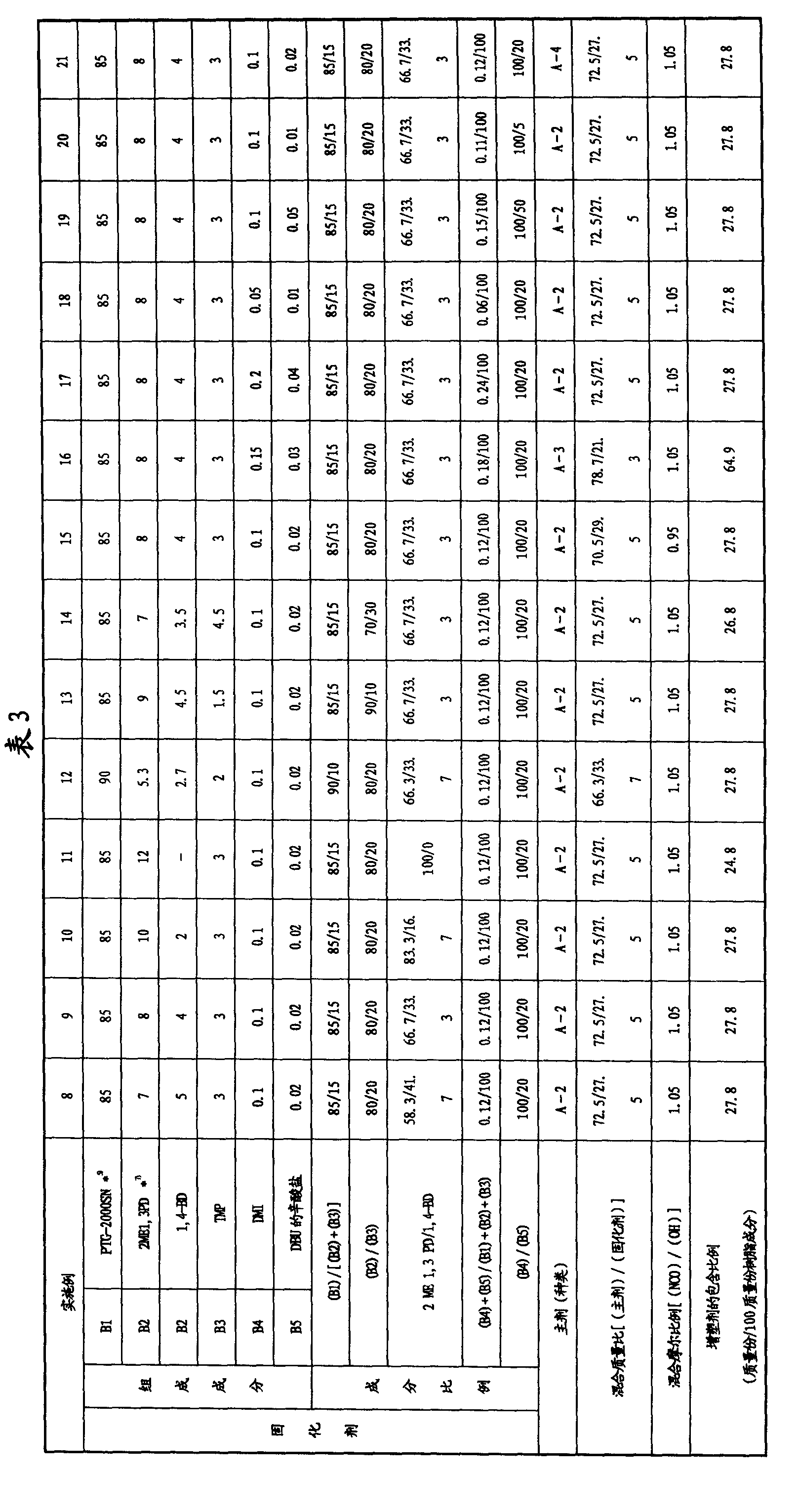

[0128] According to the formula described in the following table 1, in the reaction vessel replaced by nitrogen, add MDI type isocyanate and PTMG, by reacting at 80 ℃ for 4 hours, obtain the polyurethane prepolymer of NCO group termination (confirm the reaction by NCO content titration end), filling it into a storage container, replacing the space of the container with nitrogen gas, sealing and cooling to room temperature, thereby obtaining the main ingredient (A) [main ingredient (A-1)].

[0129] The NCO content and viscosity (75° C.) of the main ingredient (A-1) composed of an NCO group-terminated polyurethane prepolymer are shown together in Table 1 below.

preparation example 2~5

[0131] According to the formula in Table 1 below, in a nitrogen-substituted reaction vessel, add MDI-based isocyanate and PTMG, and react at 80°C for 4 hours to obtain an NCO-terminated polyurethane prepolymer (confirm the end of the reaction by NCO content titration) , add a plasticizer to it and stir and mix for about 1 hour, then fill it into a container, use nitrogen to replace the space in the container, and then seal it to obtain the main ingredient (A) [main ingredient (A-2)~ (A-5)].

[0132] Table 1 below shows the NCO content and viscosity (75° C.) of the main ingredients (A-2) to (A-5) each composed of an NCO group-terminated polyurethane prepolymer and a plasticizer.

[0133]

Preparation Example 1

Preparation example 2

Preparation example 3

Preparation Example 4

Preparation Example 5

Main agent (A)

A-1

A-2

A-...

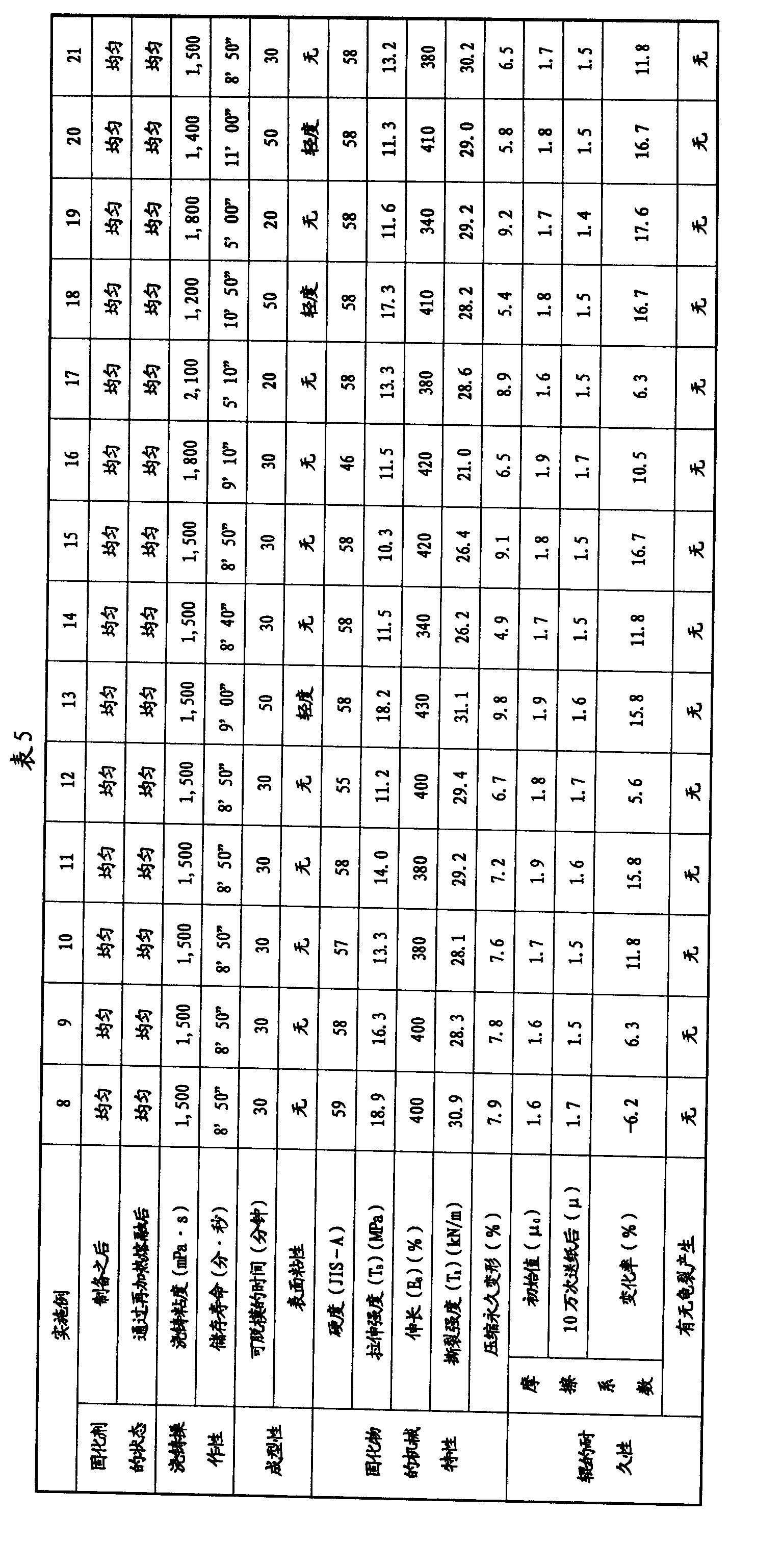

Embodiment 1

[0142] According to the formula shown in the following table 2, long-chain diol (B1), short-chain diol (B2), short-chain triol (B3), catalyst (B4), heat-sensitive catalyst (B5) ) were mixed for 1 hour to prepare curing agent (B). Visual observation of the state of the curing agent (B) after preparation (liquid temperature = 60° C.) revealed a uniform state with no suspension and no phase separation. The obtained curing agent (B) was filled in a storage container, the space of the container was replaced with nitrogen gas, and then it was sealed and cooled to room temperature. Thus, the curing agent (B) is cured.

[0143] Then, the curing agent (B) was heated (reheated) to 60° C., and the state of the curing agent (B) thus melted was visually observed to reveal a homogeneous state without phase separation.

[0144] Next, the composition of the present invention was prepared by mixing the main ingredient (A-1) heated to 60° C. and the curing agent (B) (liquid temperature = 60° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com