Prepn process of monodisperse nanometer Fe-Pt alloy particle

A nano-alloy, monodisperse technology, applied in the field of materials, can solve the problems of harsh equipment technical requirements, expensive raw materials, and highly toxic iron pentacarbonyl, and achieve the effects of convenient and simple product processing, narrow particle size distribution, and stable reaction system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Fully dissolve 0.000031mol of chloroplatinic acid and 0.0000625mol (1:2) ferrous chloride tetrahydrate in 2ml of absolute ethanol, add 0.1g of sodium oleate and 2mg of diphenyl crown ether, and oscillate ultrasonically for 10 minutes .

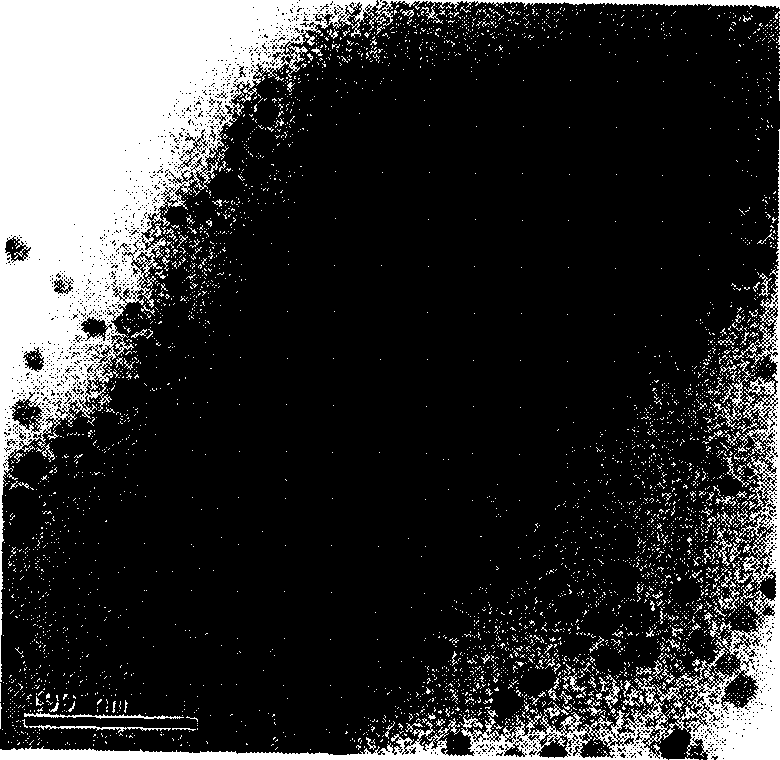

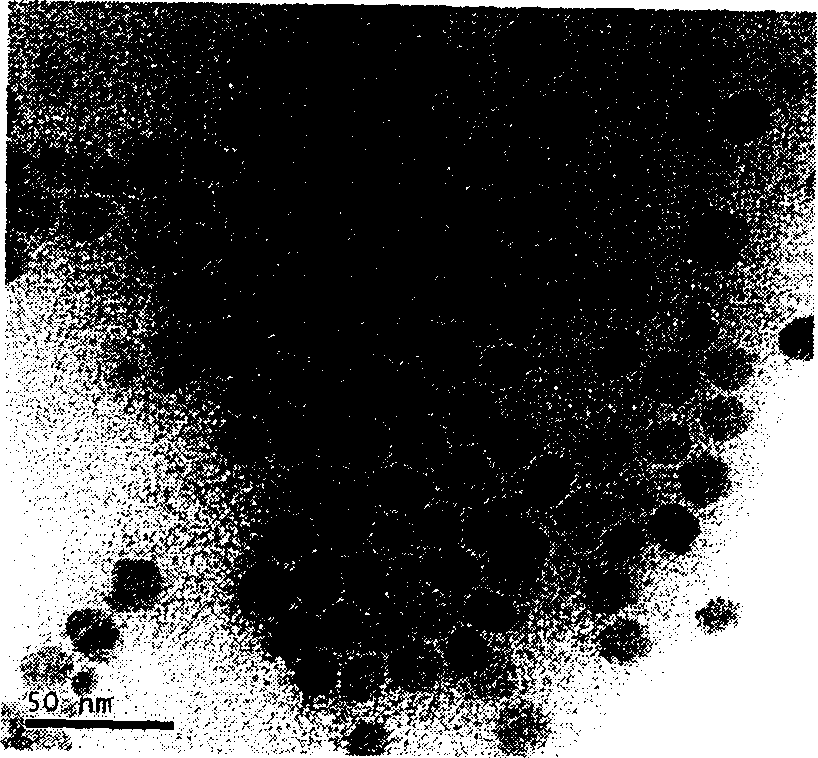

[0028] 2. Accurately measure 3ml of 1,2-propanediol and 1ml of oleic acid to fully mix, add to the system of step (1), ultrasonicate for 10 minutes, make it fully mixed, and then add the entire mixed system into the reaction autoclave , heated at 120°C for 15 hours. After the reaction, wash the particles with ethanol for 3-5 times, and centrifuge at 5000 rpm for 10 minutes to obtain the desired product with a particle size of 10-15nm. Finally, the particles can be redispersed in absolute ethanol or chloroform. from figure 1 , figure 2 The existence of the product can be clearly seen in the TEM electron microscope photos shown.

Embodiment 2

[0030] 1. Fully dissolve 0.000031 mol of chloroplatinic acid and 0.000125 mol (1:4) ferric oxalate in 4 ml of absolute ethanol, add 0.1 g of sodium oleate and 2 mg of diphenyl crown ether, and oscillate ultrasonically for 15 minutes.

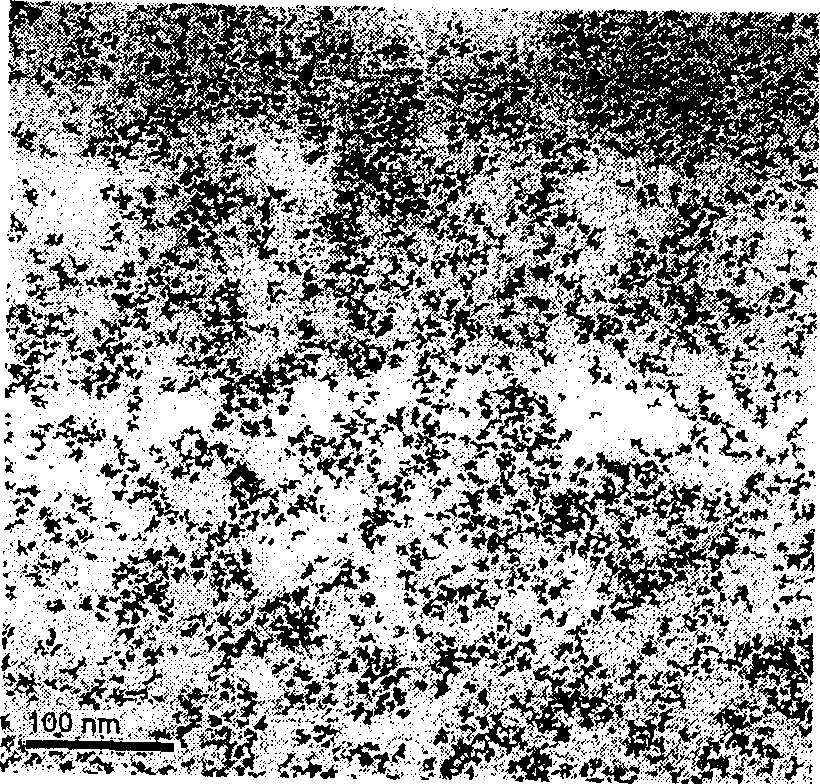

[0031] 2. Accurately measure 2ml of 1,2-propanediol and 1ml of oleic acid to fully mix, add to the system of the first step, ultrasonicate for 10 minutes to make it fully mixed, and then add the entire mixed system to the reaction autoclave together, Heated at 140°C for 10 hours. After the reaction, the particles were washed with ethanol for 3-5 times, and centrifuged at 3500 rpm for 15 minutes. The desired product is obtained, and its particle size is 2-6nm. Finally, the particles can be redispersed in absolute ethanol or chloroform. from image 3 The existence of the product can be clearly seen in the TEM electron microscope photos shown.

Embodiment 3

[0033] 1. Fully dissolve 0.000031 mol of chloroplatinic acid and 0.0000625 mol (1:2) ferrous chloride tetrahydrate in 3 ml of ethylene glycol, add 0.1 g of sodium oleate and 2 mg of diphenyl crown ether, and oscillate ultrasonically for 12 minutes.

[0034] 2. Accurately measure 3ml of 1,2-propanediol and 1ml of oleic acid to fully mix, add to the system of step (1), ultrasonicate for 10 minutes, make it fully mixed, and then add the entire mixed system into the reaction autoclave , heated at 120°C for 13 hours. After the reaction, the particles are washed with ethanol for 3-5 times, and centrifuged at 3000 rpm for 20 minutes to obtain the desired product with a particle size of 2-7nm. Finally, the particles can be redispersed in absolute ethanol or chloroform. from Figure 4 The existence of the product can be clearly seen in the TEM electron microscope photos shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com