Non-combustion dye check cleaning liquid and preparing method thereof

A technology for coloring flaw detection and cleaning liquid, which can be used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve problems such as uneconomical production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The composition ratio of the non-combustible colored flaw detection cleaning liquid is as follows:

[0041] Ingredient wt%

[0042] Glycine isobutyl ester 80

[0043] Propylene Glycol Carbonate 12

[0044] Gunner TSHG 8

[0045] The preparation steps are as follows:

[0046] ① Screen raw materials, the purity of each raw material is chemically pure;

[0047] ②Weigh the raw materials, and weigh the amount of each raw material according to the above formula ratio;

[0048] ③At room temperature, the raw materials are mixed in the middle reaction vessel, sealed and stirred for 2 hours;

[0049] ④After the stirring is finished, filter through a 200-mesh screen to obtain the finished product of cleaning liquid;

[0050] ⑤ Put the obtained permeate product into a pressure tank using nitrogen as a propellant to make an aerosol tank product.

Embodiment 2

[0052] The composition formula of the non-combustible colored flaw detection cleaning liquid is as follows:

[0053] Ingredients: wt%

[0054] Glycine isobutyl ester (base solvent) 30

[0055] Propylene carbonate (hydrate adjuvant) 40

[0056] Cannoning agent TSHG (degassing agent) 30

Embodiment 3

[0058] The composition formula of the non-combustible colored flaw detection cleaning liquid is as follows:

[0059] Ingredients: wt%

[0060]Glycine isobutyl ester 65

[0061] Propylene Glycol Carbonate 22

[0062] Gunner TSHG 13

[0063] The preparation steps and usage methods of Example 2 and Example 3 are the same as those of Example 1, except that the proportions of the ingredients are different during the configuration, and chemically pure raw materials are also selected for each of the raw materials.

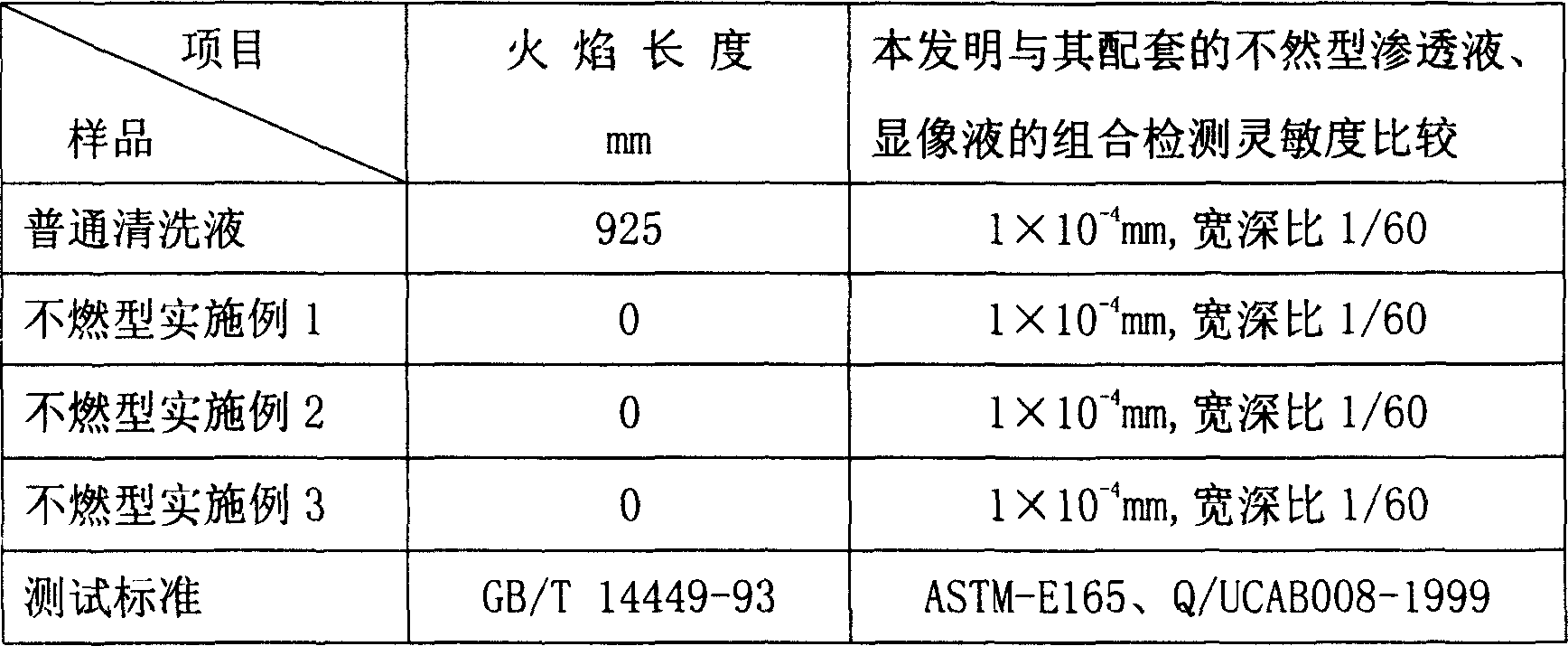

[0064] The non-combustible penetrant flaw detection cleaning liquid prepared according to the component ratios of Example 1, Example 2 and Example 3 is used together with the non-combustible penetrant flaw detection developing liquid and the non-combustible colored penetrating liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com