A kind of manufacture method of organic bentonite

A manufacturing method and technology of bentonite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as unfavorable coating use, unfavorable removal of sandy components, and large slurry consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

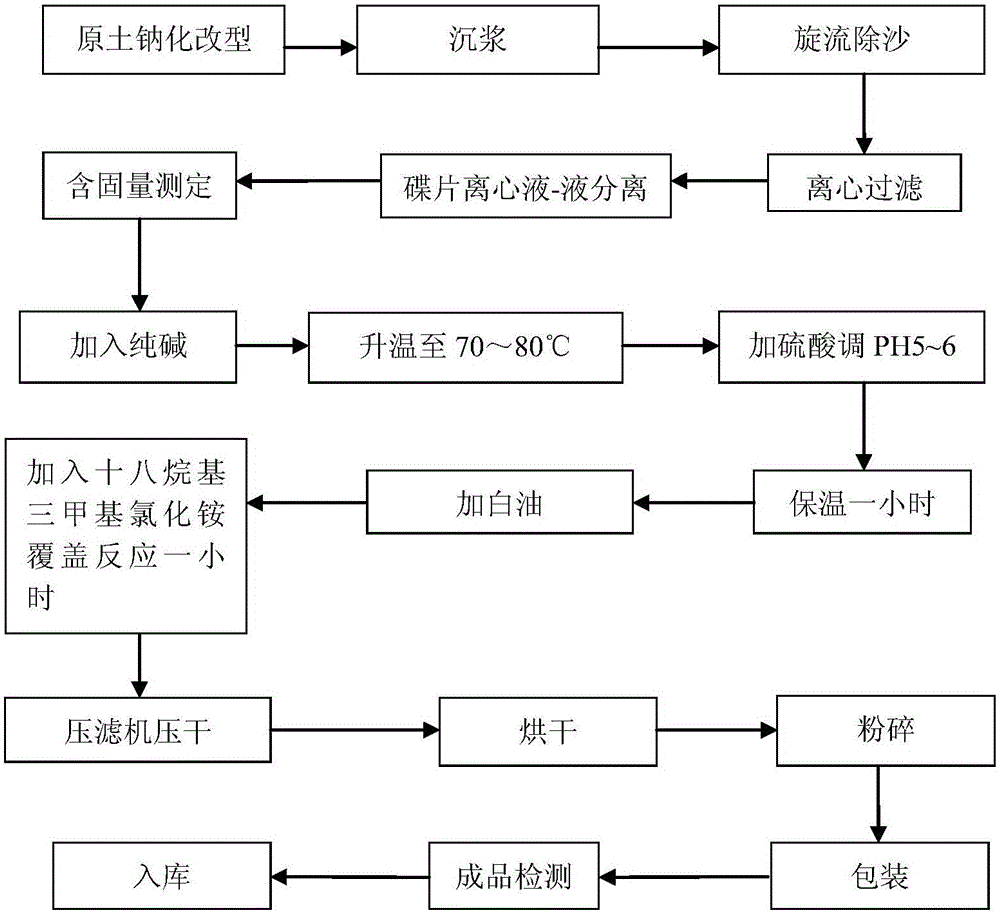

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] As shown in the figure, a kind of manufacture method of organobentonite of the present invention follows the design principle as follows:

[0033] 1. The principle of sodium modification

[0034] The target mineral montmorillonite of bentonite is a kind of aluminosilicate mineral with unique properties. Type structure, the crystal layer has water molecules and exchangeable cations. Si in the layer of montmorillonite structural unit 4+ Can be A1 3+ substitution, Al within the octahedral layer 3+ Often referred to as Mg 2+ , Fe 3+ , Zn 2+ Such as multivalent ion replacement, because low-valent cations replace high-valent cations, the structure generates redundant negative valence, in order to protect electrical neutral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com