High-temperature resisting one-chip integrated micro-sensor structure and system integrating method

A monolithic integration, micro-sensor technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as inapplicability, achieve low production cost, achieve miniaturization, improve space utilization and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

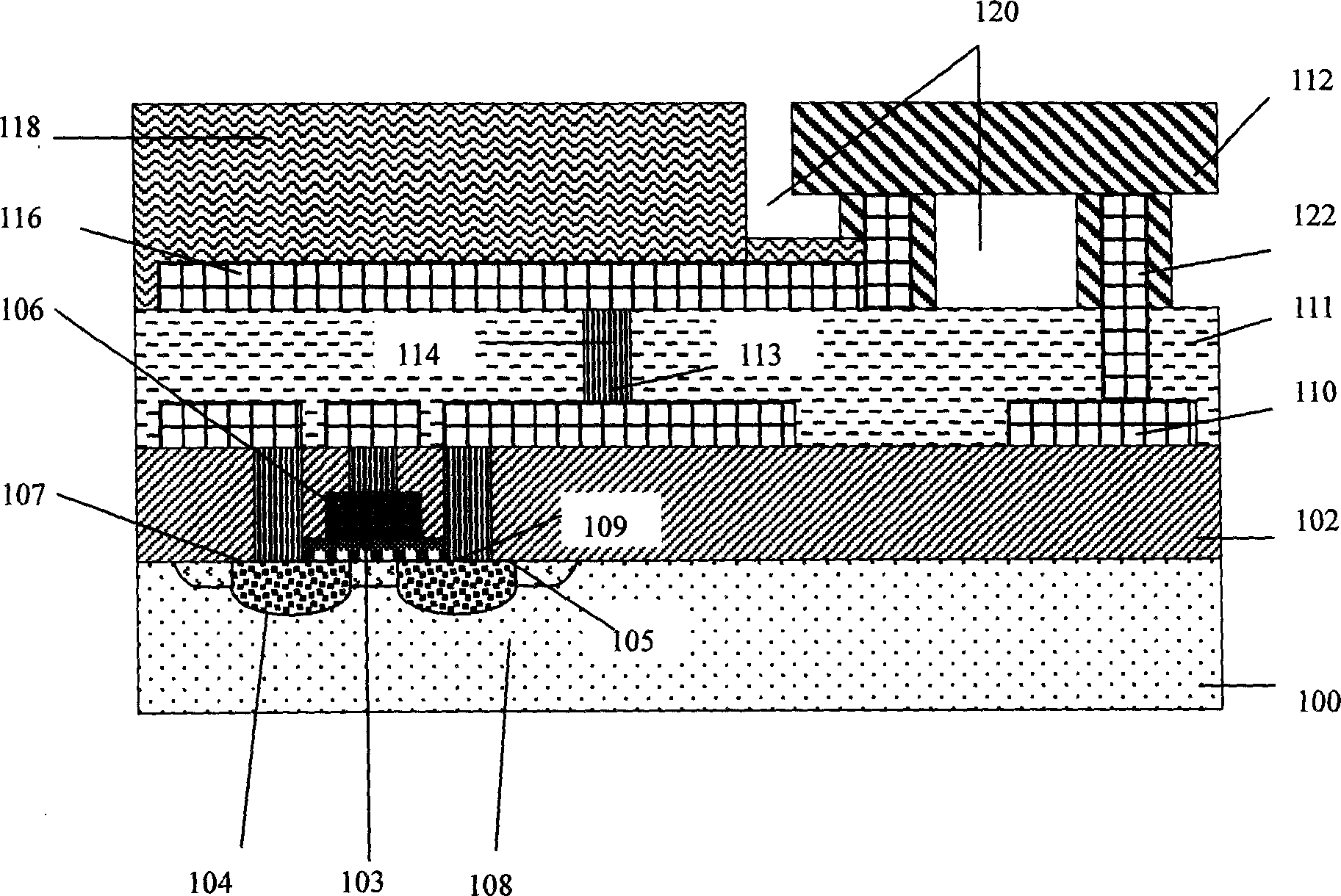

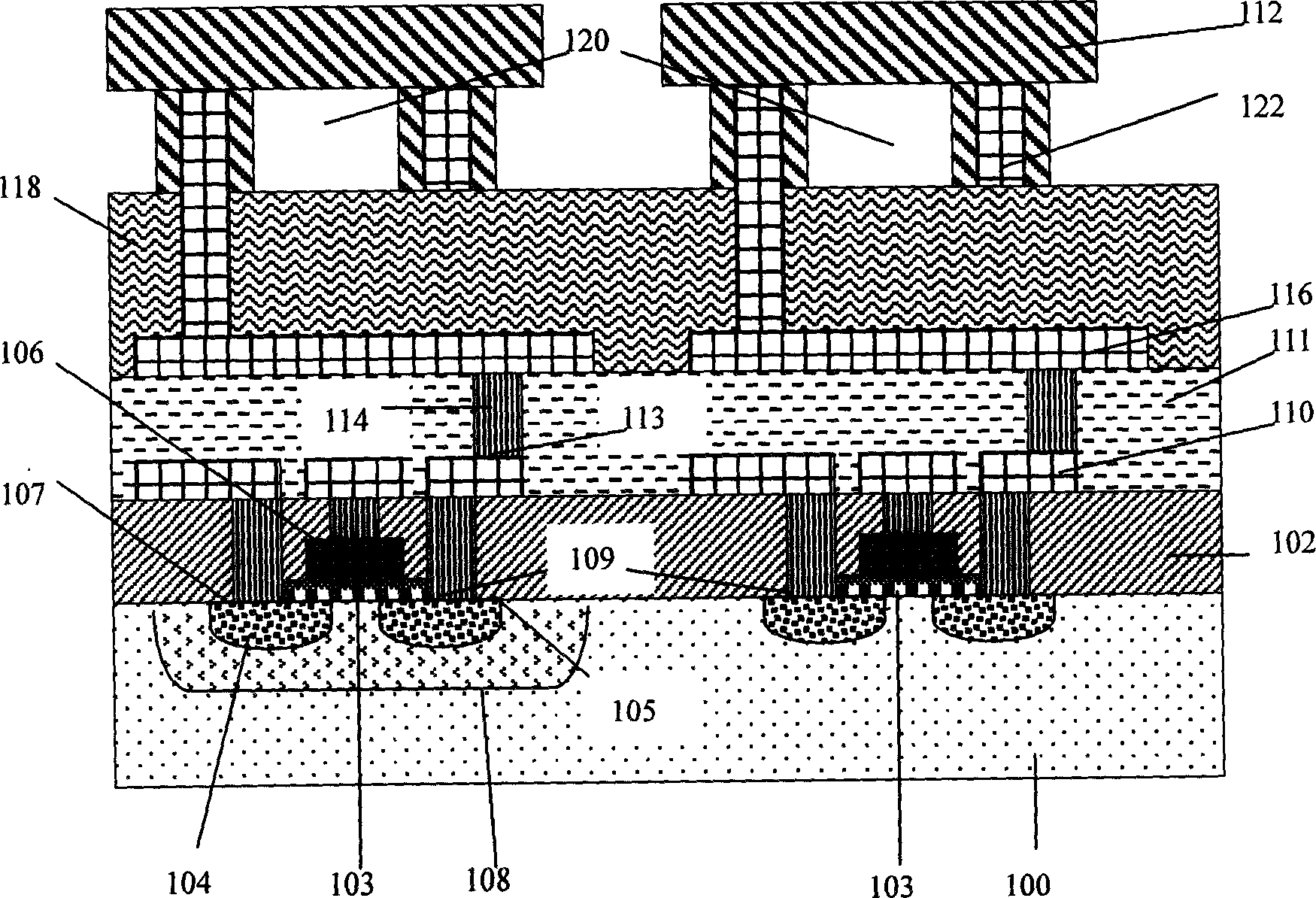

[0045] The invention proposes a monolithic integration method of "manufacturing IC first and then microstructure". This method is compatible with the standard CMOS process. The multilayer interconnection line of the integrated circuit is made of refractory metal silicide or refractory metal. After the IC is completed, the microstructure is made on the same plane, that is, the microstructure and the IC circuit are on the same plane, or in the same plane as the IC circuit. IC is the substrate, and microstructures are fabricated vertically to form monolithically integrated arrays or multifunctional microsensor systems.

[0046] see figure 1 .

[0047] First, SiO is oxidized on the cleaned silicon substrate 100 2 The film 102 is used as a field oxide layer, and the photolithography or etching process is used to open concave holes on the field oxide layer to define the specific positions of the source, drain and gate of the MOS transistor, and the N or P well 108 is formed by a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com