Musical instrument, musical instrument assembly preparation

A technology for musical instruments and components, which is applied in the field of preparation of musical instruments and musical instrument components, can solve the problems of insufficient aesthetics, poor sound quality and resonance, and long working hours at welding places, and achieves good sound wave resonance and transmission, good sound quality and resonance, Reduce the effect of workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

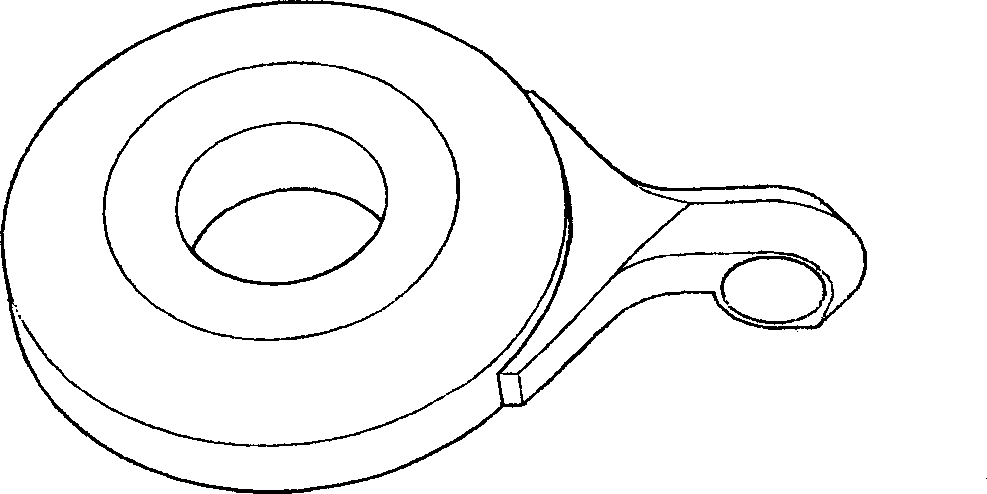

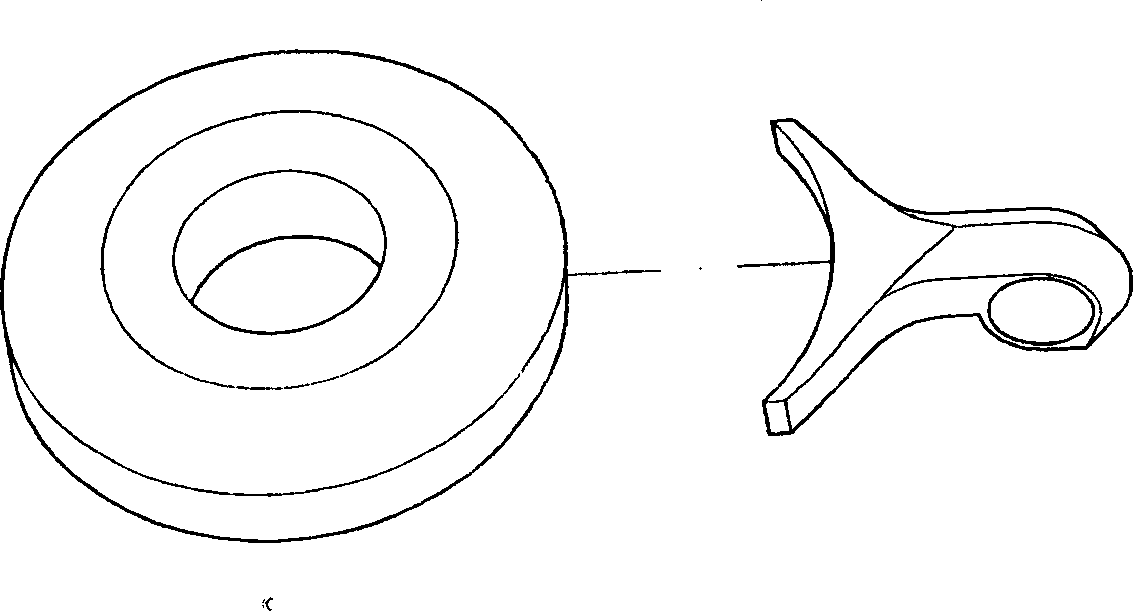

Image

Examples

Embodiment Construction

[0024] The following is a description of an embodiment of the present invention.

[0025] The preparation of the musical instrument of the present invention and its components mainly includes the following procedures:

[0026] Choose to mix and knead at least one metal powder with a binder to form granular materials, and the volume percentage of the binder is between 7% and 61%;

[0027] forming the aforementioned granules into a preform blank;

[0028] removing the binder from the aforementioned preform blank;

[0029] Sintering occurs and the blank is shrunk to preform dimensions.

[0030] The metal powder particles used in this method are generally selected to have a particle size of 50 μ or less. And in this method, the particle size of the metal powder is selected according to the high, medium and low pitch, wherein the low pitch has a larger particle size, the middle pitch has an intermediate particle size, and the treble has a smaller particle size.

[0031] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com