Method for recovering ammonia from purge gas

A technology of purge gas and ammonia recovery, applied in the field of medium and small chemical fertilizer plants, can solve the problems of low added value of dilute ammonia water and ammonium bicarbonate, pollution, consumption of large amounts of water and energy, etc., and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Isobaric Recovery in Theory and Experiment

[0037] Depending on the manufacturer, the outlet pressure of the bleed gas is also different, and the ammonia content is also directly related to the temperature. We choose a representative temperature of 15°C, 2.2Mpa, 1m 3 The exhaust gas is calculated later, and the specific composition is shown in Table 3.

[0038]

[0039] 1.1 Theoretical calculation

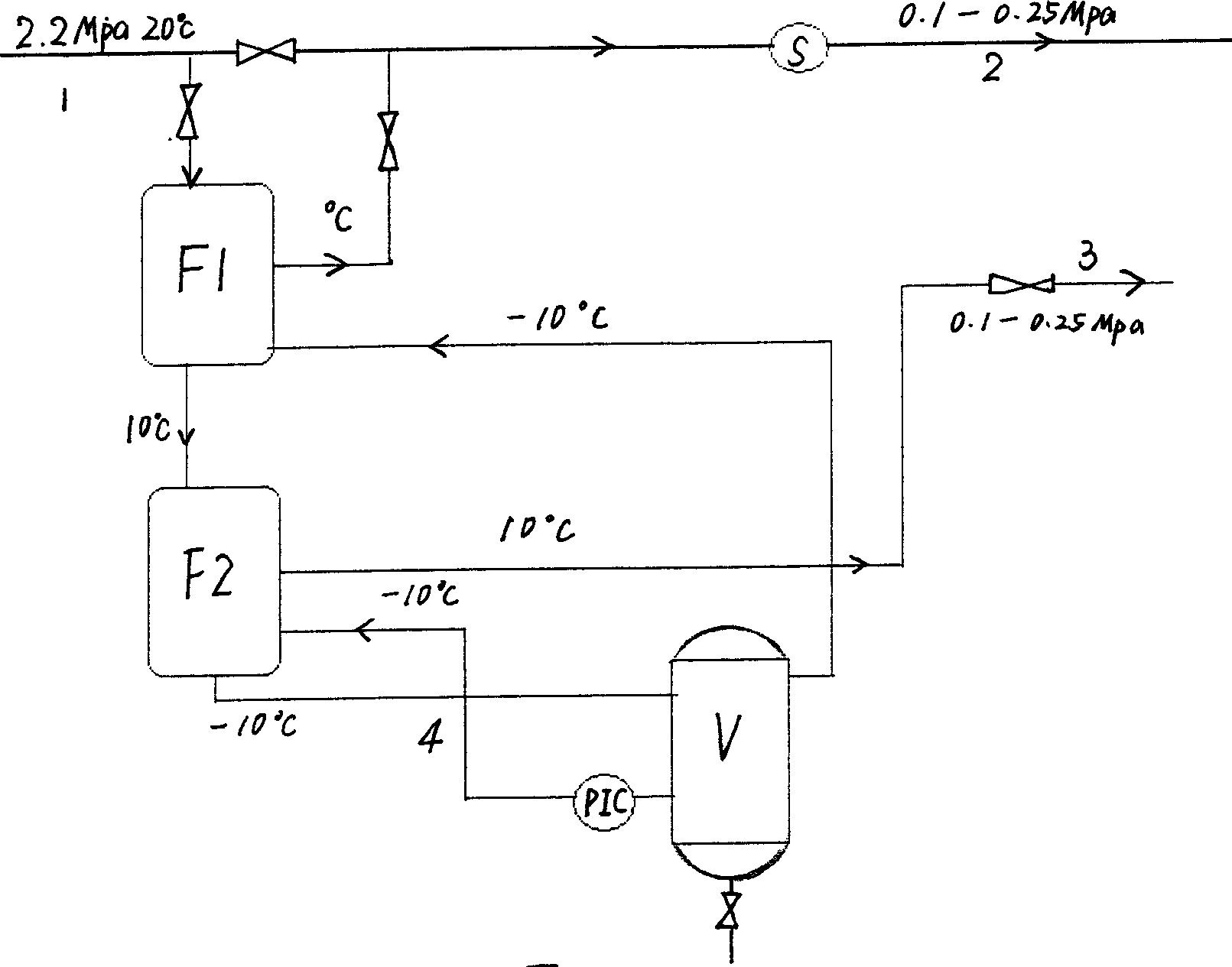

[0040] according to figure 1 Schematic diagram of the isobaric recovery process of vented ammonia:

[0041] At 0.25Mpa, the vaporization temperature of liquid ammonia is given by the gram-gram equation (that is, formula 1)

[0042] ln(0.25 / 0.1)=23300 / 8.314(1 / 239.8-1 / T 2 )

[0043] (assuming ΔH vap Does not change with temperature in a small range)

[0044] Solution: T 2 =265.04K=-8.1℃[actually -14℃, for the convenience of calculation, we take -10℃]

[0045] Look up the table to get the ΔH of the vaporization of liquid ammonia at -10°C vap =22....

Embodiment 2

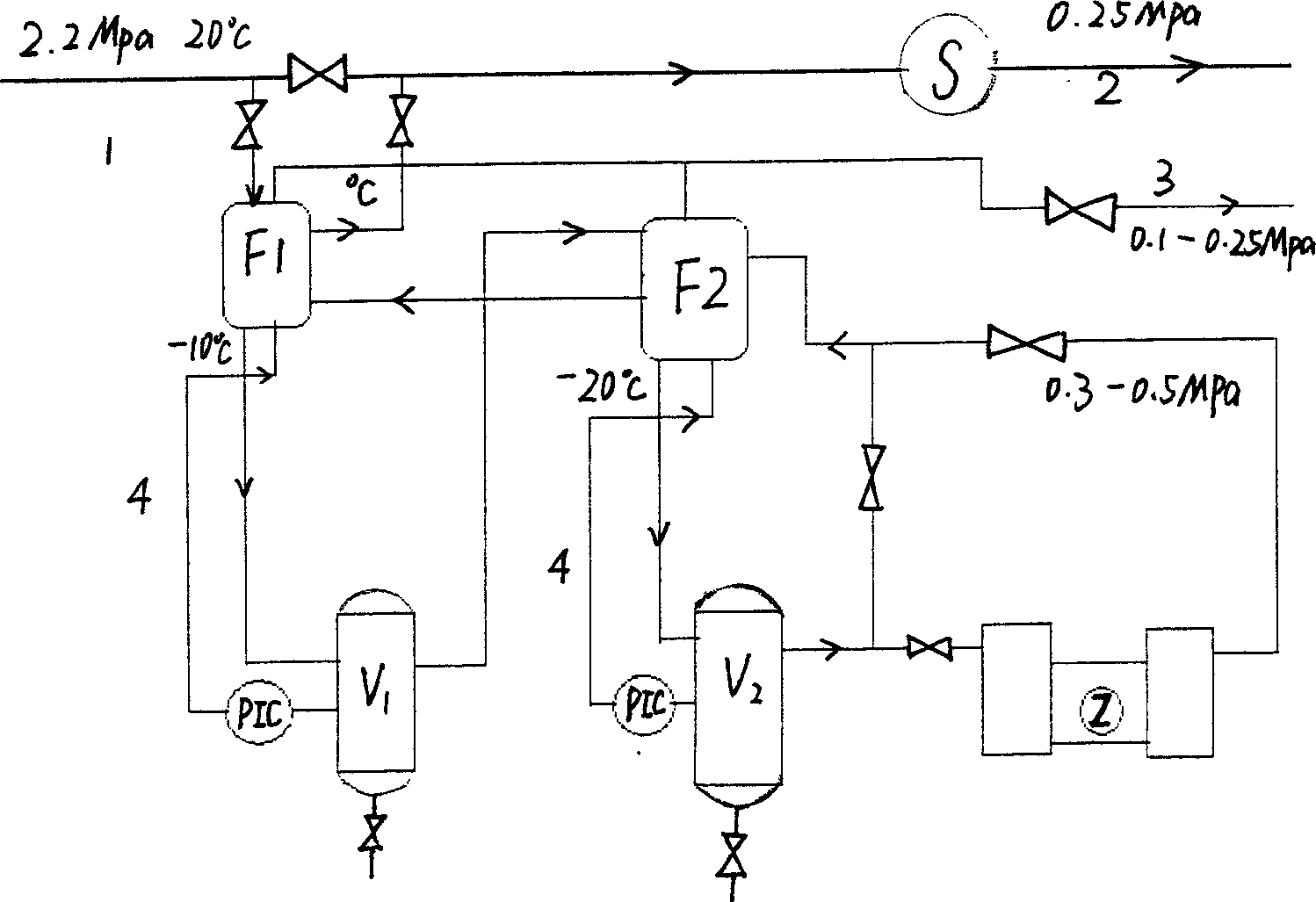

[0091] Example 2: Release gas and ammonia equal pressure + energy conversion and recovery

[0092] Such as figure 2As shown, isobaric recovery can generally reduce the temperature of the purge gas to -10°C, so that most of the ammonia can be condensed and separated, and the recovery rate is about 70%. After improvement, energy conversion is carried out after isobaric recovery, and the Joule-Thomson effect is used to further reduce the temperature of the purge gas after recovering most of the ammonia, and then perform heat exchange, which can further increase the ammonia recovery rate. The improved device is shown as figure 2 , after passing through two heat exchangers, the temperature of the purge gas is reduced to below -20°C, and the recovery rate of ammonia will reach above 80%. When the recovery rate is 80%, the composition and related parameters of the remaining gas are shown in Table-7 .

[0093] At -20°C, the saturated vapor pressure of liquid ammonia is P=0.1966Mp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com