Sn-Ag-Cu-Cr-X lead-free soldering material and its preparation

A lead-free solder, sn-ag-cu-cr-x technology, applied in the direction of welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of solder joint peeling, high price, high melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

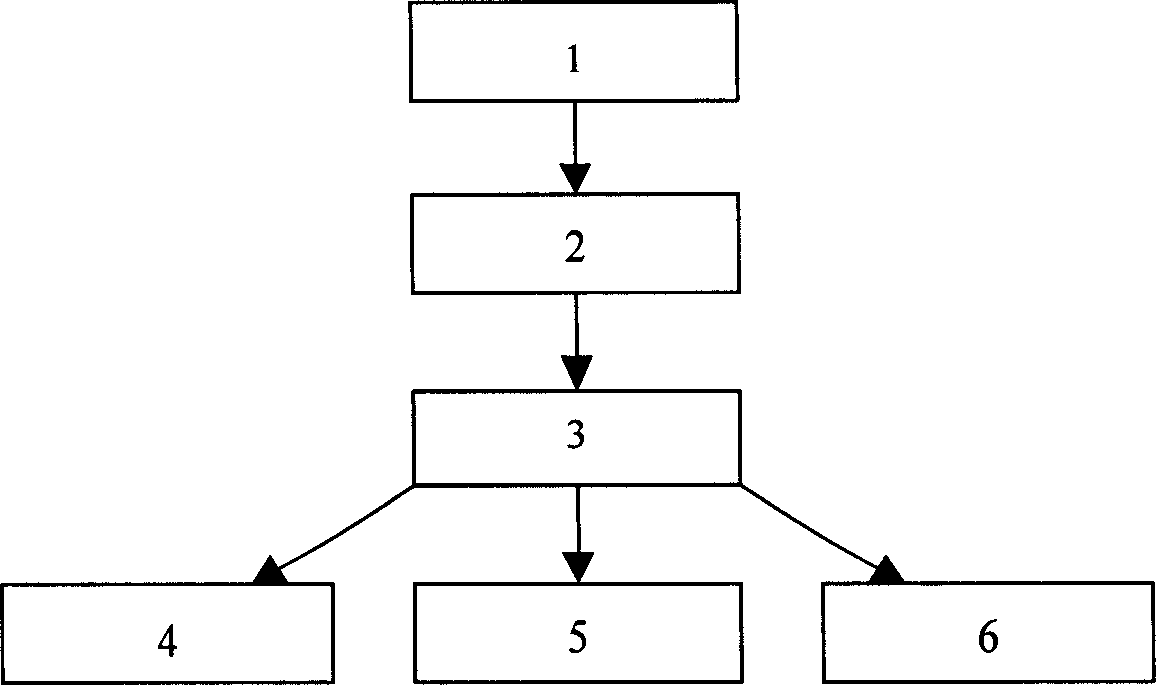

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of Sn-Ag1.0-Cu0.9-Cr0.6-Al0.001:

[0023] According to weight percentage, Ag is 1.0%, Cu is 0.9%, Cr is 0.6%, and Al is 0.001%. The preparation process is as follows: 5.0 kg of Sn-Ag20 master alloy is prepared in a resistance furnace according to the weight ratio; 5.0 kg of Sn-Cu10 master alloy, 5.0 kg of Sn-Cr7.5 master alloy are prepared in a vacuum intermediate frequency induction melting furnace, and Sn-Cr7.5 master alloy is 5.0 kg. 5.0kg of Al5.0 master alloy, 5.0kg of Sn-P5.0 master alloy; during the preparation process: ① first melt the weighed pure Sn to 500°C in a resistance furnace, add the weighed Ag strip, stir and melt to the furnace temperature 400~500°C, stirring and holding for half an hour, pouring into square ingots to prepare Sn-Ag20 master alloy; ②First melt the weighed pure Sn in a vacuum induction melting furnace to 650°C, add the weighed pure Cu flakes , stirred and melted to the furnace temperature of 500-600°C, stirred and...

Embodiment 2

[0024] Example 2 Preparation of Sn-Ag2-Cu0.7-Cr0.3-Al0.01:

[0025] According to the weight percentage, Ag is 2.0%, Cu is 0.7%, Cr is 0.3%, and Al is 0.01%. The preparation of the master alloy is the same as Example 1. Weigh 20.0g of Sn-Ag20 master alloy, 14.0g of Sn-Cu10 master alloy, 8.00g of Sn-Cr7.5 master alloy, 0.40g of Sn-Al5 master alloy, and 157.6g of pure Sn. Then melt pure Sn in a resistance furnace and heat it to 300°C, add Sn-Ag20 master alloy, Sn-Cu10 master alloy, Sn-Cr7.5 master alloy and Sn-Al5 master alloy in turn, heat to 300°C for 10min, pour In the cylindrical mold, after the ingot is completely solidified, remelt the ingot to 300 ° C for 10 minutes, pull out the surface oxide slag, and pour it into the mold to make the ingot solder for later use.

Embodiment 3

[0026]Embodiment 3 Preparation of Sn-Ag2-Cu0.7-Cr0.1-P0.05:

[0027] According to weight percentage, Ag is 2.0%, Cu is 0.7%, Cr is 0.1%, and P is 0.05%. The preparation of the master alloy is the same as Example 1. Weigh 20.0g of Sn-Ag20 master alloy, 14.0g of Sn-Cu10 master alloy, 2.70g of Sn-Cr7.5 master alloy, 2.0g of Sn-P5 master alloy, and 1.3g of pure Sn16. First melt pure Sn in a resistance furnace and heat it to 300°C, then add Sn-Ag20 master alloy, Sn-Cu10 master alloy, Sn-Cr7.5 master alloy and Sn-P5 master alloy in turn, heat to 300°C for 10 minutes, and pour In the cylindrical mold, after the ingot is completely solidified, remelt the ingot to 300 ° C for 10 minutes, pull out the surface oxide slag, and pour it into the mold to make the ingot solder for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com