Fermented cordycepin micrograin, its production and use

A technology for fermenting Cordyceps sinensis and mycelium, which can be used in applications, food preparation, fungi, etc., and can solve the problems of large dosage, small dosage, and difficulty in making tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

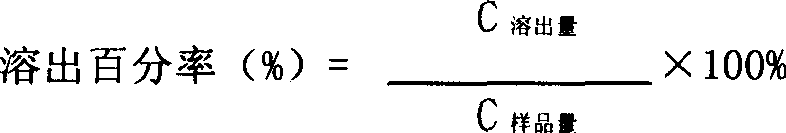

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Cordyceps micropowder and preparation

[0058] Take 500g of Cordyceps grass powder and dry it. The TC-20 fluidized bed jet pulverizer (Nanjing Tianmu Super Micro Technology Development Co., Ltd.) was used for jet pulverization, and the pulverization time was 2 hours. Take an appropriate amount of the pulverized powder and measure it with a laser diffraction particle size analyzer. The particle size test statistics show that the particle size distribution of more than 85% of the powder is between 5-35um. Weigh it at the same time. The powder yield is 62.0%. The glycoside content is 0.33%.

Embodiment 2

[0059] Embodiment 2: Cordyceps micropowder and preparation

[0060] Take 500g of Cordyceps grass powder and dry it. Use the GKZ-80 type vibrating ultrafine pulverizer to vibrate and pulverize, and the pulverizing time is 2 hours. Take an appropriate amount of the micropowder obtained by the pulverization method, and measure it with a laser diffraction particle size analyzer. The particle size test statistics show that the particle size distribution of more than 85% of the micropowder is between 3-65um. Weigh it at the same time, and the powder yield is 48.0%, and measure The adenosine content is 0.28%.

Embodiment 3

[0061] Embodiment 3: capsule and preparation

[0062] Cordyceps micropowder 200g, make 1000 No. 1 capsules according to conventional technology, each contains 0.2g of Cordyceps micropowder.

[0063] For chronic bronchitis, 2 capsules each time, 2 times a day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com