Contact oxidizing H circulation pipe film biological reactor

A membrane bioreactor and circulating pipe technology, which is applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problem that the membrane bioreactor's ability to treat wastewater is reduced, the viscosity of the mud-water mixture is increased, and the power consumption of aeration is increased. and other problems, to achieve the effect of reducing energy consumption per unit of water production, improving processing capacity, and low sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

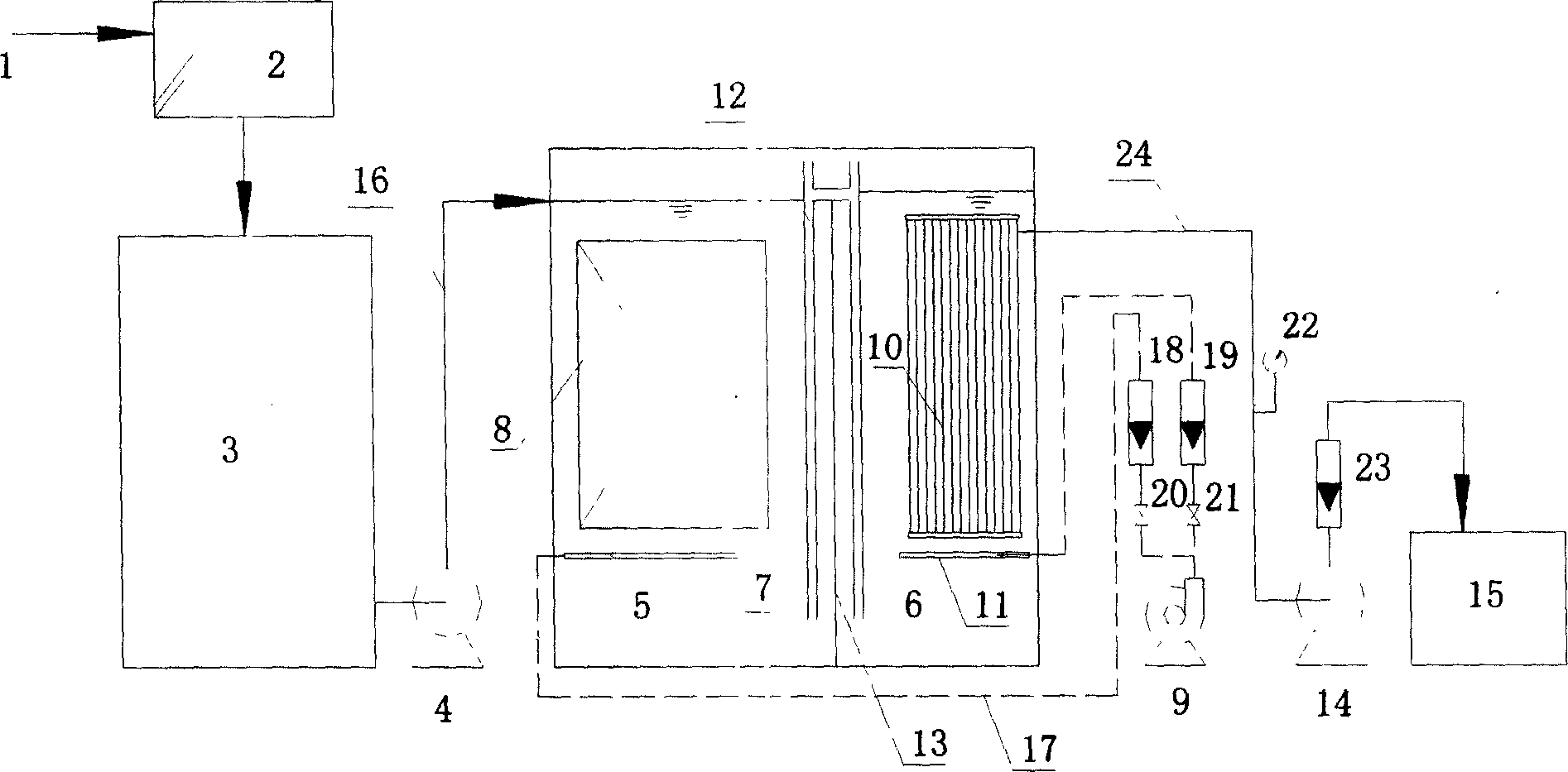

[0018] The sewage enters the raw water pool (3) after passing through the grid well (2), and then enters the biological contact oxidation reaction pool (5) under the transportation of the sewage pump (4), and contacts with the biofilm on the filler (8), and the waste water Pollutants are removed under the action of microbial adsorption and oxidative decomposition, and the required oxygen is provided by the aeration pipe (7). The mixed solution enters the membrane tank (6) through the H or h circulation pipe (12), and the mixed solution in the membrane tank (6) flows upwards under the lifting effect of the airflow blown out of the membrane flushing air tube (11), and passes through the partition (13 ) enters the biological contact oxidation reaction tank (5), and the mixed solution is circulated. Driven by the suction pump (14), the treated water is filtered through the membrane module (10) and continuously discharged into the clear water pool (15). The air required for system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com