Preparation method and application of anionic fiber modifier

An anion and modifier technology, applied in the field of the preparation of anionic fiber modifiers, can solve the problems such as the improvement of environmental protection quality, the loss of fine fibers, and the increase of sludge concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

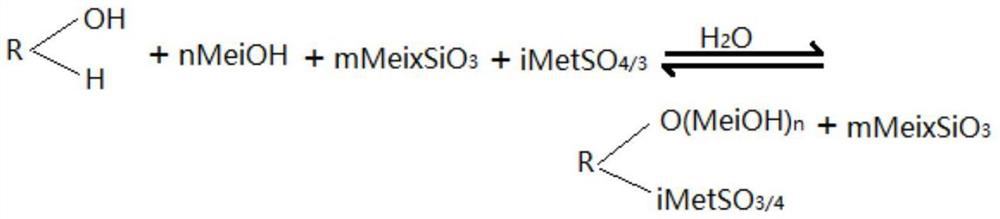

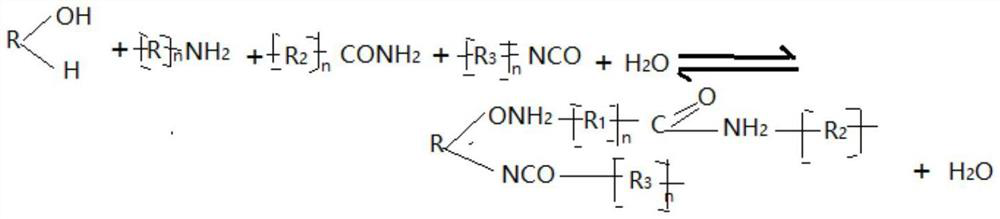

Method used

Image

Examples

Embodiment Construction

[0038] The preparation method and application of the anionic fiber modifying agent of the present invention will be further described in detail below in conjunction with specific examples.

[0039] The research and development and specific implementation process of the anionic fiber modifier of the present invention are as follows. In order to facilitate the understanding of the technical solution concept and principle of the present invention, specific raw materials and processes will be used to illustrate, but it cannot be understood as a patent for the invention The limitation of the scope, the protection scope of the patent of the present invention should be based on the appended claims.

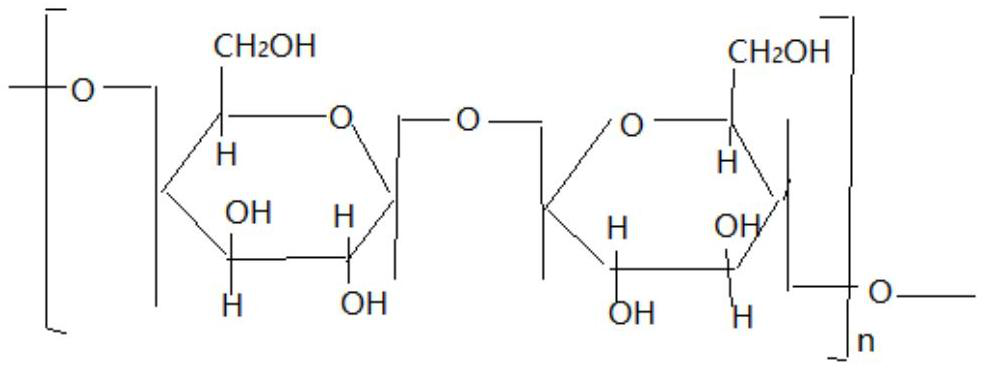

[0040] 1. Exploration basis

[0041] The waste paper raw materials used in the paper industry are so diverse that it is difficult to list them in detail. According to the type of waste paper, it can be divided into three types: unbleached mechanical pulp waste paper, bleached chemical p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electronegativity | aaaaa | aaaaa |

| electronegativity | aaaaa | aaaaa |

| electronegativity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com