Novel high performance alkaline fuel cell

A fuel cell and battery technology, applied in the field of electrochemical energy storage, can solve problems such as the impossibility of large-scale promotion and use, and achieve the effects of overcoming the acidification of the electrolyte, good electrochemical performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

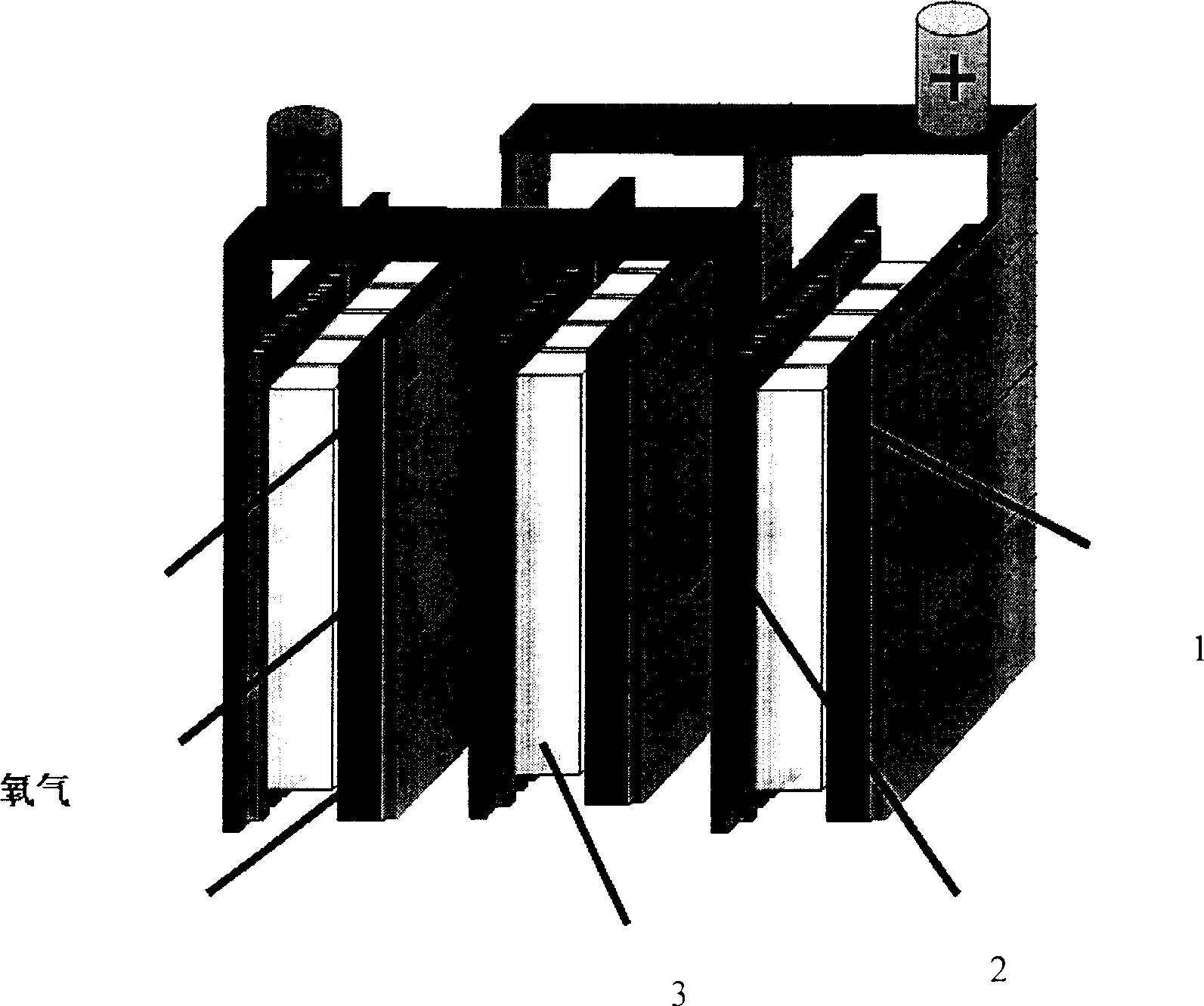

Method used

Image

Examples

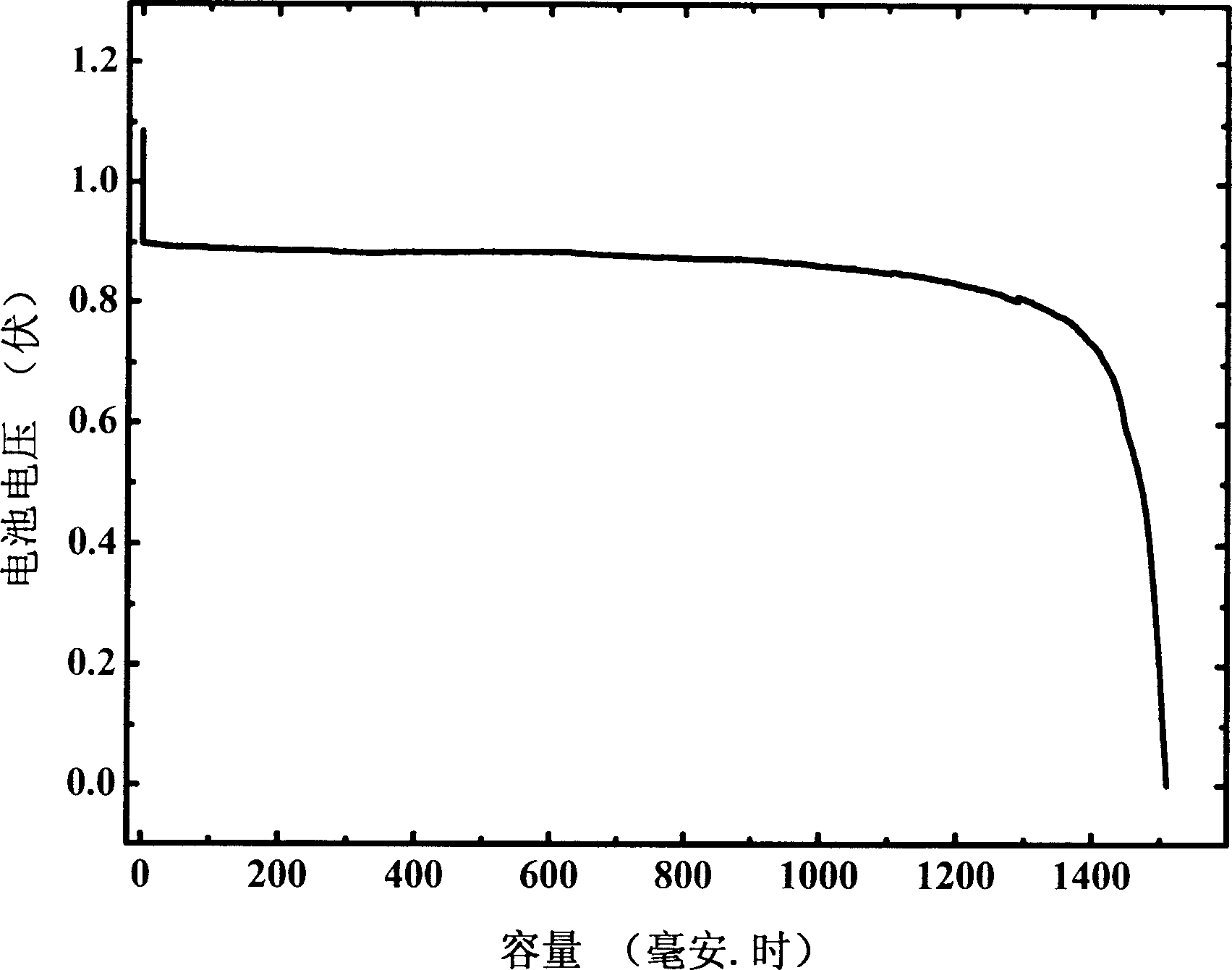

Embodiment 1

[0030] Negative pole adopts AB 5 Type mixed rare earth hydrogen storage alloy MmNi 3.35 co 0.75 mn 0.4 al 0.3 : Negative electrode composition by: MmNi 3.35 co 0.75 mn 0.4 al 0.3 : Nickel powder: PTFE=80: 10: 10 by weight and mix it into a slurry, spread it on the foamed nickel mesh, and roll it to form a film. The cathode film uses manganese dioxide as a catalyst. Catalytic layer composition: MnO 2 : Activated carbon: binder=20:65:15 weight ratio mixed into a slurry, rolled into a film. Composition of the gas diffusion layer: acetylene black: binder = 60:40 mixed into a slurry, rolled into a film. The gas diffusion layer and the catalyst layer are sequentially pressed onto the foamed nickel mesh to form the positive electrode membrane. MmNi in the negative electrode 3.35 co 0.75 mn 0.4 al 0.3 The mass is: 200mg / cm 2 .The mass of manganese dioxide in the positive electrode is: 2mg / cm 2 .The electrolyte uses 200ml KOH, which contains 0.4g KBH 4 .at 5mA / cm 2 U...

Embodiment 2

[0032] Negative pole adopts AB 5 Type mixed rare earth hydrogen storage alloy MmNi 3.8 mn 0.55 co 0.6 Ti 0.05 , the positive electrode uses manganese dioxide as a catalyst. The rest is the same as in Example 1, and the steps and conditions in Example 1 are followed for slurry mixing, electrode coating and battery preparation. The solution uses 200ml KOH, which contains 0.4g KBH 4 .at 5mA / cm 2 Under the current density, the working voltage of the battery is 0.86V, and the capacity is 1497mAh (see Table 1 for details).

Embodiment 3

[0034] Negative pole adopts AB 2 Type zirconium alloy ZrCr 0.8 Ni 1.2 , the positive electrode uses manganese dioxide as a catalyst. The rest is the same as in Example 1, and the steps and conditions in Example 1 are followed for slurry mixing, electrode coating and battery preparation. The solution uses 200ml KOH, which contains 0.4g KBH 4 .at 5mA / cm 2 Under the current density, the working voltage of the battery is 0.85V, and the capacity is 1489mAh (see Table 1 for details).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com