Application of high fine collected ash from cement factory dust collector as admixture of concrete

A technology for collecting dust and concrete, which is applied in the application field of high-fine dust collectors in cement plant dust collectors as concrete admixtures, which can solve the problems of difficult availability and high price of high-fine admixtures, and improve compatibility , Improve durability, improve workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

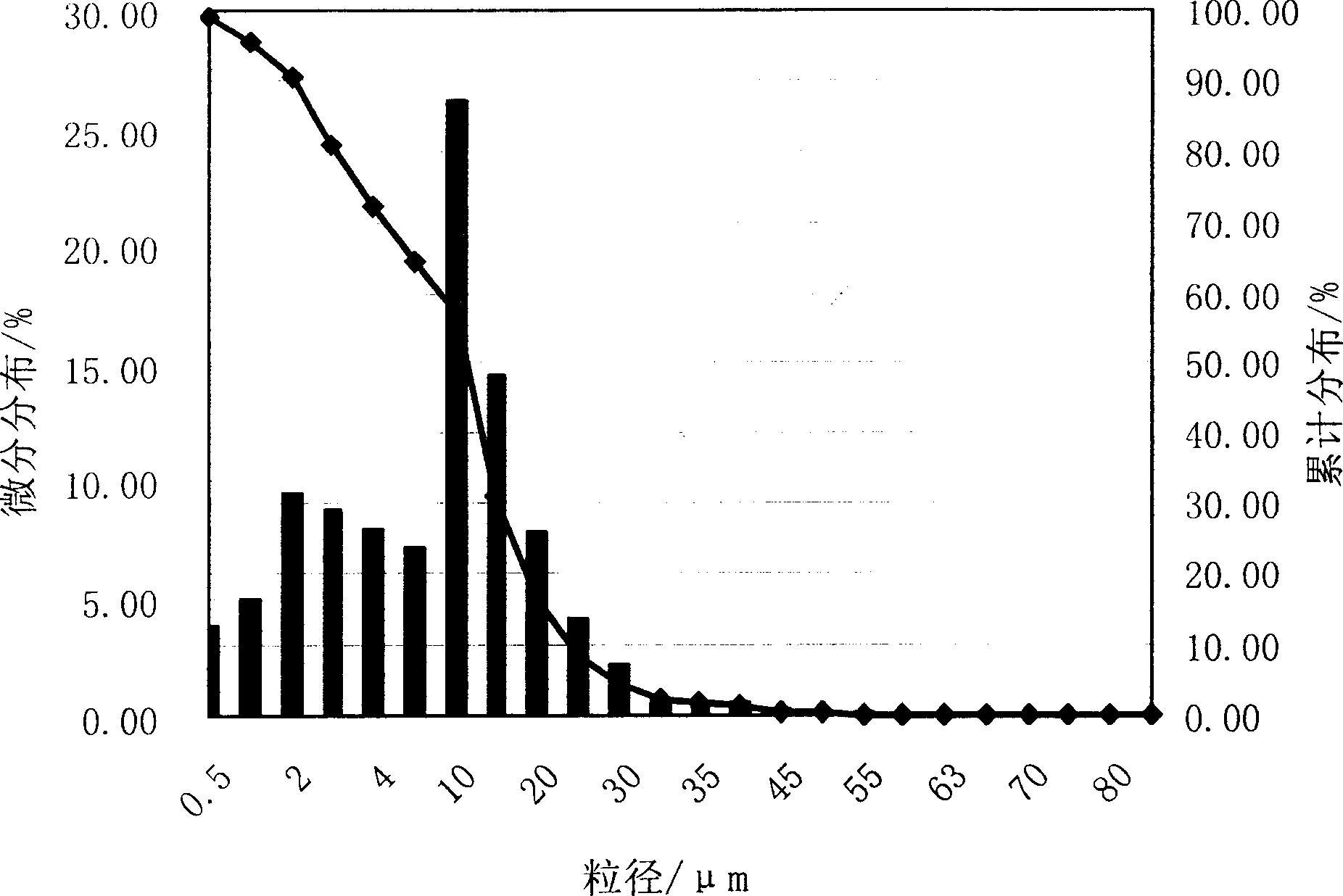

Image

Examples

Embodiment 1

[0027] Table 1:

[0028]

[0029] Note: A space means no data

Embodiment 2

[0030] Example 2: The mixing test of different mixing amounts of high-fine dust collector in concrete of different strength grades.

[0031] Table 2:

[0032] Wait

[0033] The cements in Table 1 and Table 2 refer to various general cements or special cements.

[0034] The water reducer in Table 1 is a component commonly used in concrete, such as naphthalene-based water reducer.

[0035] The composite admixtures in Table 1 are commercially available fine materials for concrete.

[0036] In Table 1 and Table 2, cement, fly ash, slag powder, composite admixture, silica fume, and high-fine dust collection ash are the cementitious materials.

[0037] The high-fine dust collection ash in the table can be directly added to the concrete raw materials, or the high-fine dust collection ash can be mixed into the cement first, or the high-fine dust collection ash can be mixed with slag powder and fly ash first. In, mixed with other raw materials, the effect is basically the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com