Preparation method of 3-chloro-2,6-diethyl aniline

A technology of diethylaniline and chloroaniline, applied in chemical recovery, organic chemistry, etc., can solve problems such as pollution, low product yield, poor quality performance, etc., and achieve the effect of simple process, high product quality and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

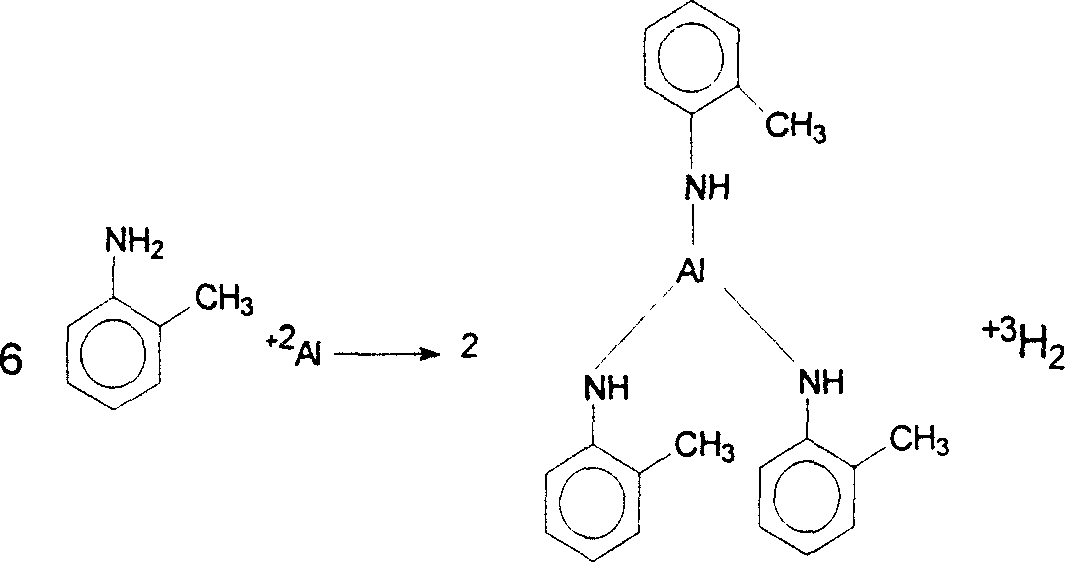

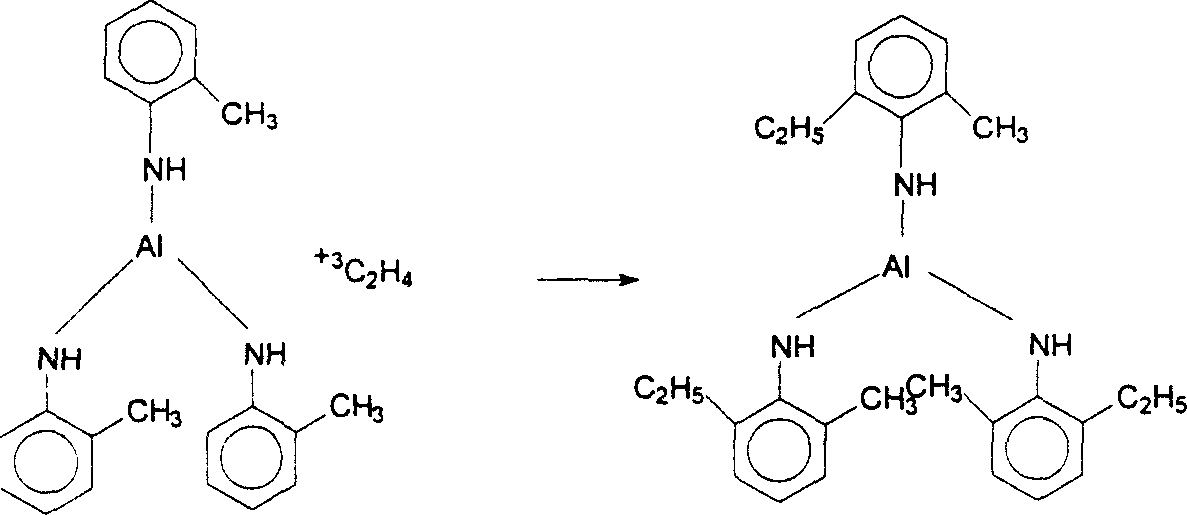

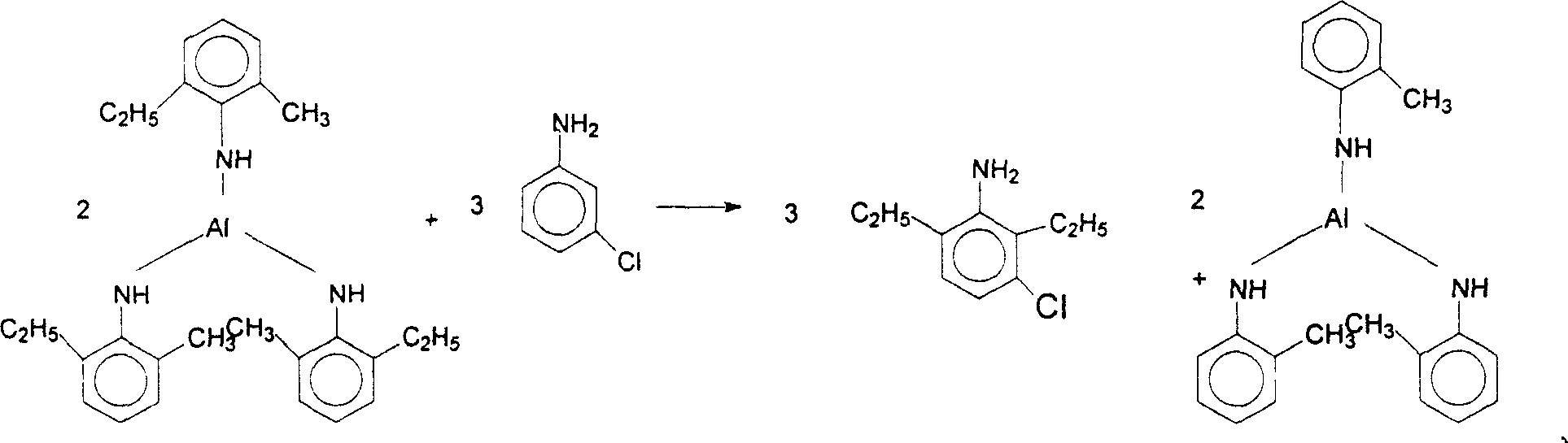

Method used

Image

Examples

Embodiment 1

[0033] In a 2000ml pressure vessel with electric heating and coil cooling, add 500 grams of aniline and 20 grams of metal aluminum powder, and feed nitrogen to replace the air in the vessel. After the container is sealed, heat it up to 260°C. When the temperature is high, turn on the cooling oil to cool down. Stir at a constant temperature of 260°C for 2 hours, and then cool to room temperature. Open the container and vent to remove the hydrogen gas formed. Add 500 grams of m-chloroaniline from the feeding port, heat up the container to 300 ° C after sealing, open the ethylene valve, press ethylene into the container, keep the pressure at 15 MPa, control the ethylene addition rate at 2 to 4 g / min, and wait until the pressure of the reaction container When rising to 16MPa, slow down the feeding speed of ethylene, and the speed is controlled at 1-2 g / min. When the pressure of the reaction vessel rises to 18MPa, stop adding ethylene, and the reaction ends. The ethylation / displac...

Embodiment 2

[0037] In a 2000ml pressure vessel with electric heating and coil cooling, add 500 grams of o-toluidine and 20 grams of metal aluminum, and feed nitrogen to replace the air in the vessel. After the container is sealed, heat it up to 300°C. When the temperature is high, turn on the cooling oil to cool it. Stir at a constant temperature of 300°C for 2 hours, and then cool to room temperature. Open the container and vent to remove the hydrogen gas formed. Add 500 grams of m-chloroaniline from the feeding port, heat up the container to 300 ° C after sealing, open the ethylene valve, press ethylene into the container, keep the pressure at 15 MPa, control the ethylene addition rate at 2 to 4 g / min, and wait until the pressure of the reaction container When rising to 16MPa, slow down the feeding speed of ethylene, and the speed is controlled at 1-2 g / min. When the pressure of the reaction vessel rises to 18MPa, stop adding ethylene, and the reaction ends. The reaction temperature is...

Embodiment 3

[0041] In a 2000ml pressure vessel with electric heating and coil cooling, add 450 grams of o-toluidine, add 25 grams of zinc, and add nitrogen to replace the air in the vessel. After sealing the container, heat up to 250°C, stir at constant temperature for 2 hours, and then cool to normal temperature. Open the container and vent to remove the hydrogen gas formed. Add 495 grams of m-chloroaniline from the feeding port, raise the temperature to 310°C, open the ethylene valve, press ethylene into the container, keep the pressure at 14MPa, control the ethylene addition rate at 2-4 g / min, and wait until the pressure of the reaction container rises to 15MPa Slow down the feeding speed of ethylene, and the speed is controlled at 1 to 2 g / min. When the pressure of the reaction vessel rises to 18MPa, the feeding of ethylene is stopped, and the reaction ends. The reaction temperature is controlled at 310°C±10°C.

[0042] After the reaction, cool down to 95°C, open the feeding and ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com