Composite heat transfer micro reactor

A micro-reactor and reactor technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of unsuitable packaging and industrial application of aluminum block heat exchange units, and achieve processing The effect of flexible materials and manufacturing methods, simple combination and packaging, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

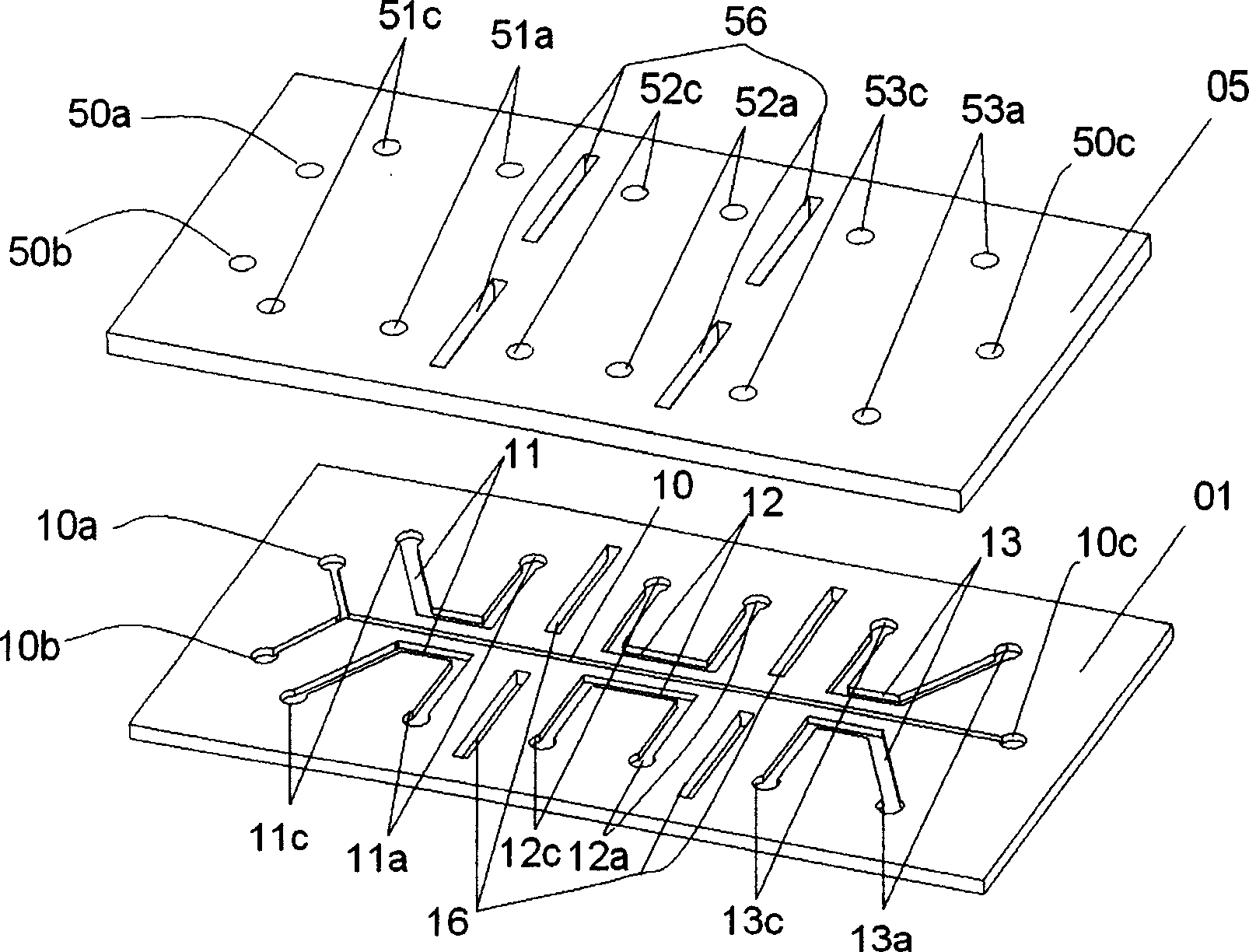

[0033] Such as figure 1 The principle of the compound heat exchange microreactor is shown, and the schematic structure includes two parts: the substrate 01 and the sealing plate 05.

[0034] The upper surface of the substrate 01 is provided with microchannels 10 for reactants to mix and react, a first group of heat exchange channels 11 arranged with the microreaction channels 10, a second group of heat exchange channels 12 arranged with the microreaction channels 10, The third group of heat exchange channels 13 arranged along with the micro-reaction channels 10 and the heat insulation groove 16 for heat insulation. Wherein, the micro-reaction channels 10 include inlets 10a, 10b and outlets 10c, the first group of heat exchange channels 11 include inlets 11a and outlets 11c, the second group of heat exchange channels 12 include inlets 12a and outlets 12c, and the third group of heat exchange channels 13 Includes inlet 13a and outlet 13c.

[0035] The sealing plate 05 is provi...

Embodiment 2

[0040] Taking the endothermic non-catalytic reaction process as an example, the formation and application of a single-layer composite heat exchange microreactor embodiment is introduced.

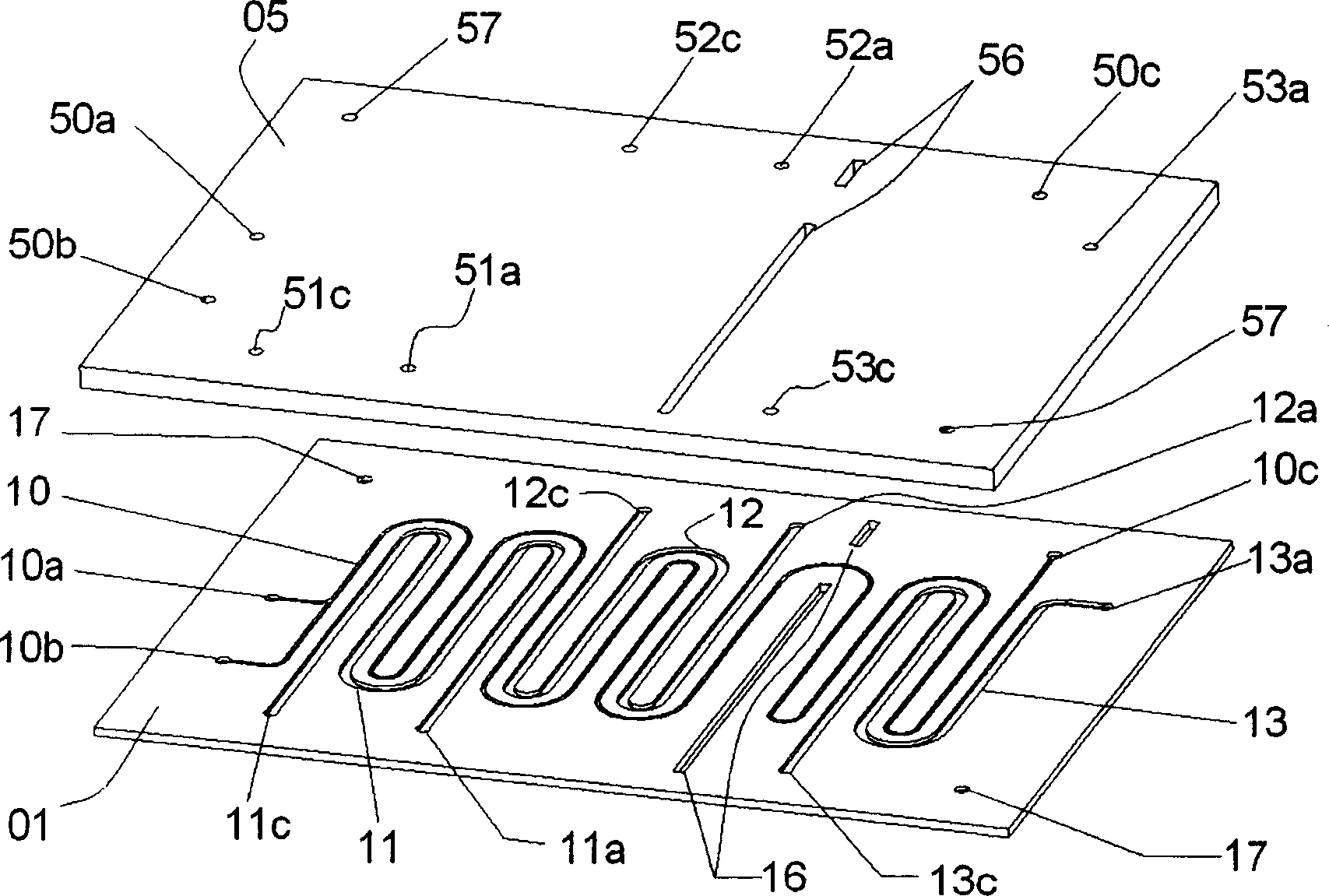

[0041] Such as figure 2 Shown is an exploded view of a single-layer structure embodiment of a composite heat exchange microreactor, which consists of a silicon material substrate 01 and a heat-resistant glass sealing plate 05.

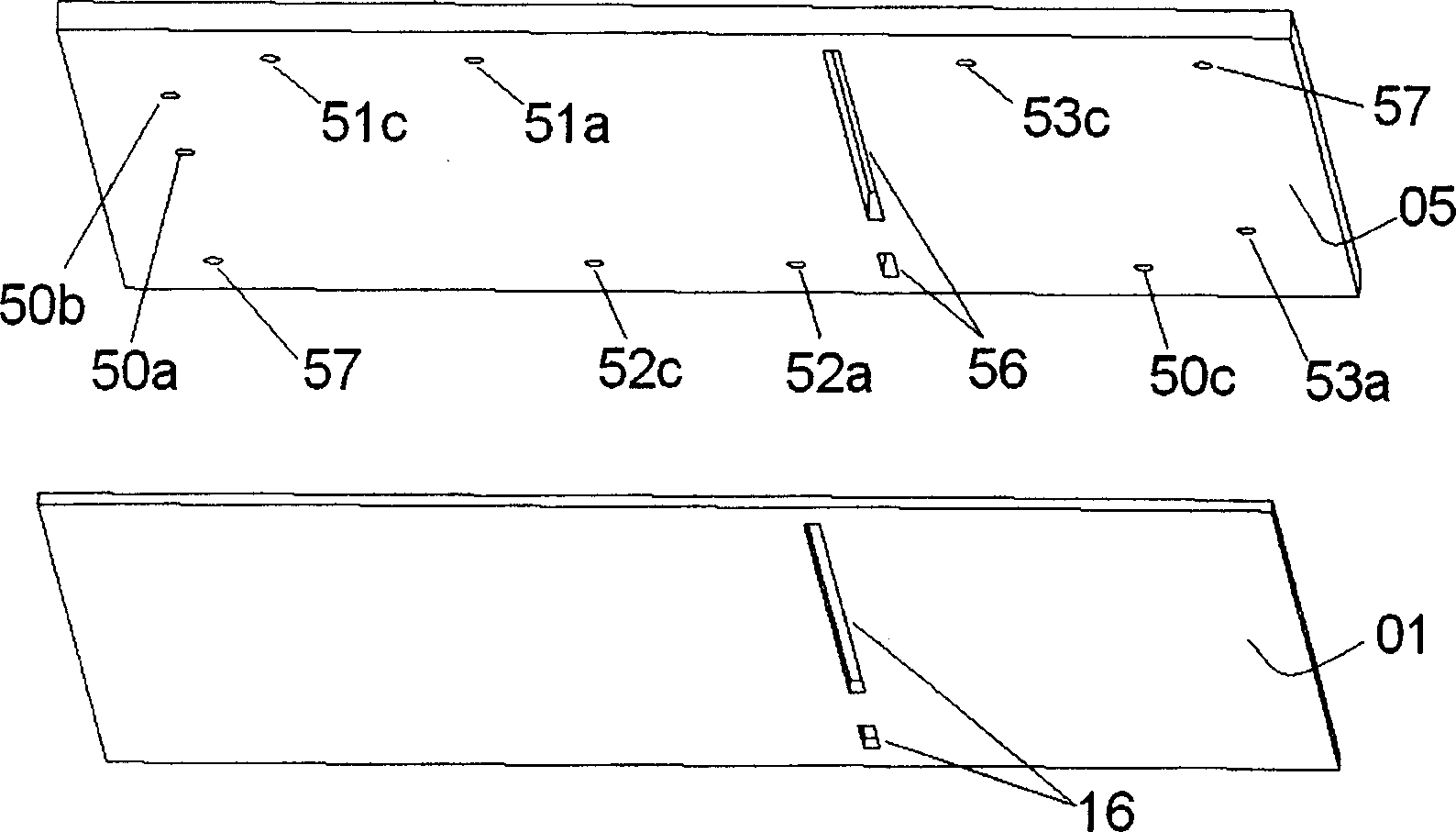

[0042] Such as image 3 As shown in the figure, an exploded view of an embodiment of a single-layer structure compound heat exchange microreactor is shown from the angle viewed from below.

[0043] Such as Figure 4 Shown is a top view of a silicon material substrate 01 in an embodiment of a single-layer structure composite heat exchange microreactor.

[0044] The silicon material is removed by plasma etching technology, and the serpentine microchannel 10 where the reactants mix and react is carved on the upper surface of the substrate 01, and the first section f...

Embodiment 3

[0049] Taking the endothermic non-catalytic reaction process as an example, the formation and application of a multi-layer structure compound heat exchange microreactor embodiment is introduced.

[0050] Such as Figure 5 Shown is an exploded view of a three-layer structure embodiment of a composite heat exchange microreactor made of 304 stainless steel. It consists of a substrate 01, a sealing plate 05 and two intermediate substrates 02 and 03 with the same characteristics.

[0051] The stainless steel material is removed by chemical etching technology, and the same channel structure is etched on the upper surfaces of the 304 stainless steel substrate 01, 304 stainless steel intermediate substrates 02 and 03. Then use the electric spark ablation technology to discharge and ablate the heat insulation gaps on the substrate 01, the intermediate substrates 02 and 03 on the electric discharge forming machine tool with thin brass electrodes. Finally, the inlets, outlets and pin p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com