Equipment for checking-out effect of heat insulation for building material, checking-out method and evaluation method

A technology of thermal insulation effect and building materials, applied in the direction of thermal development of materials, thermal conductivity of materials, preparation of samples for testing, etc. The conduction efficiency cannot fully reflect the actual effect of the thermal insulation material, and the reproducibility and reliability are not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

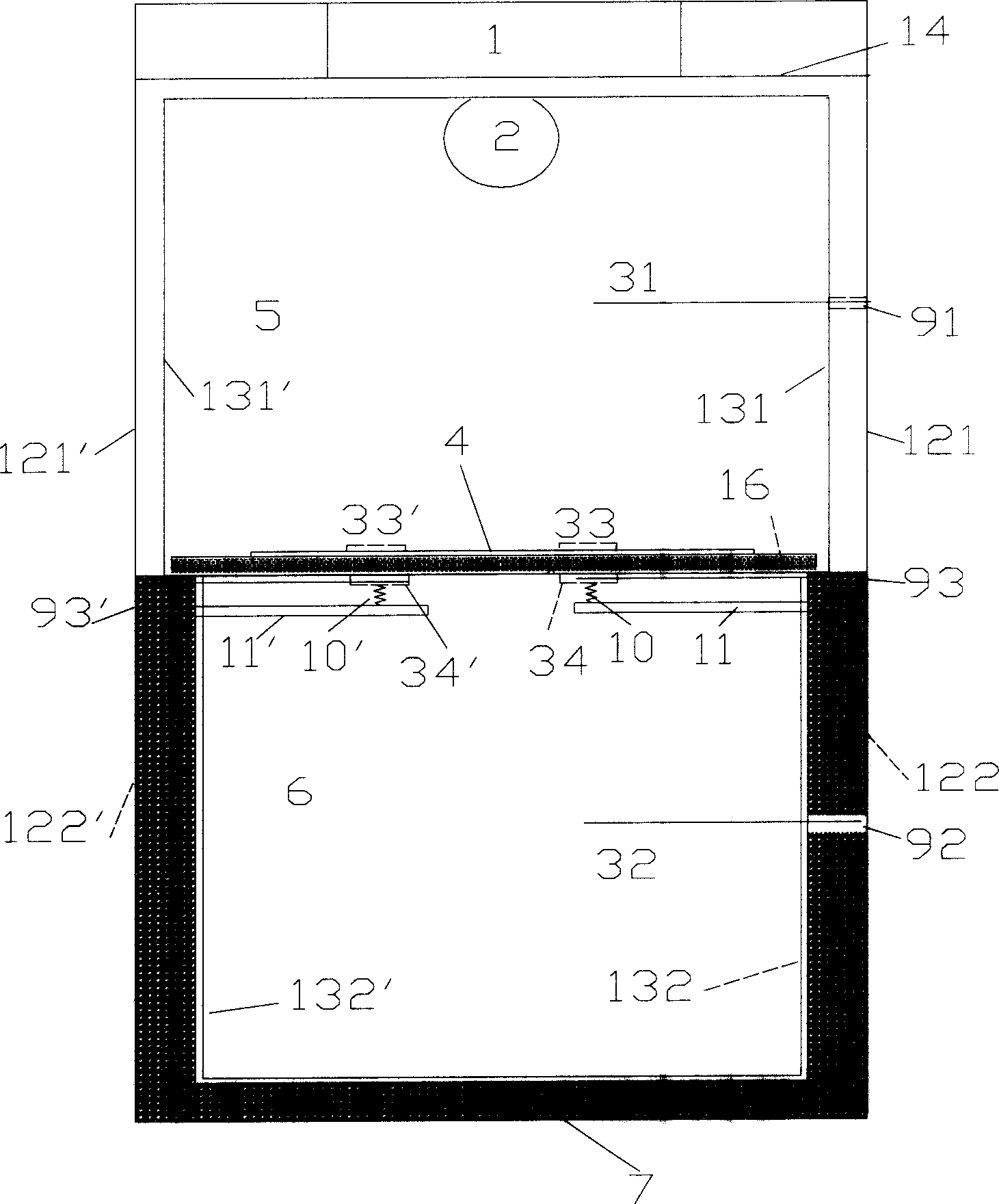

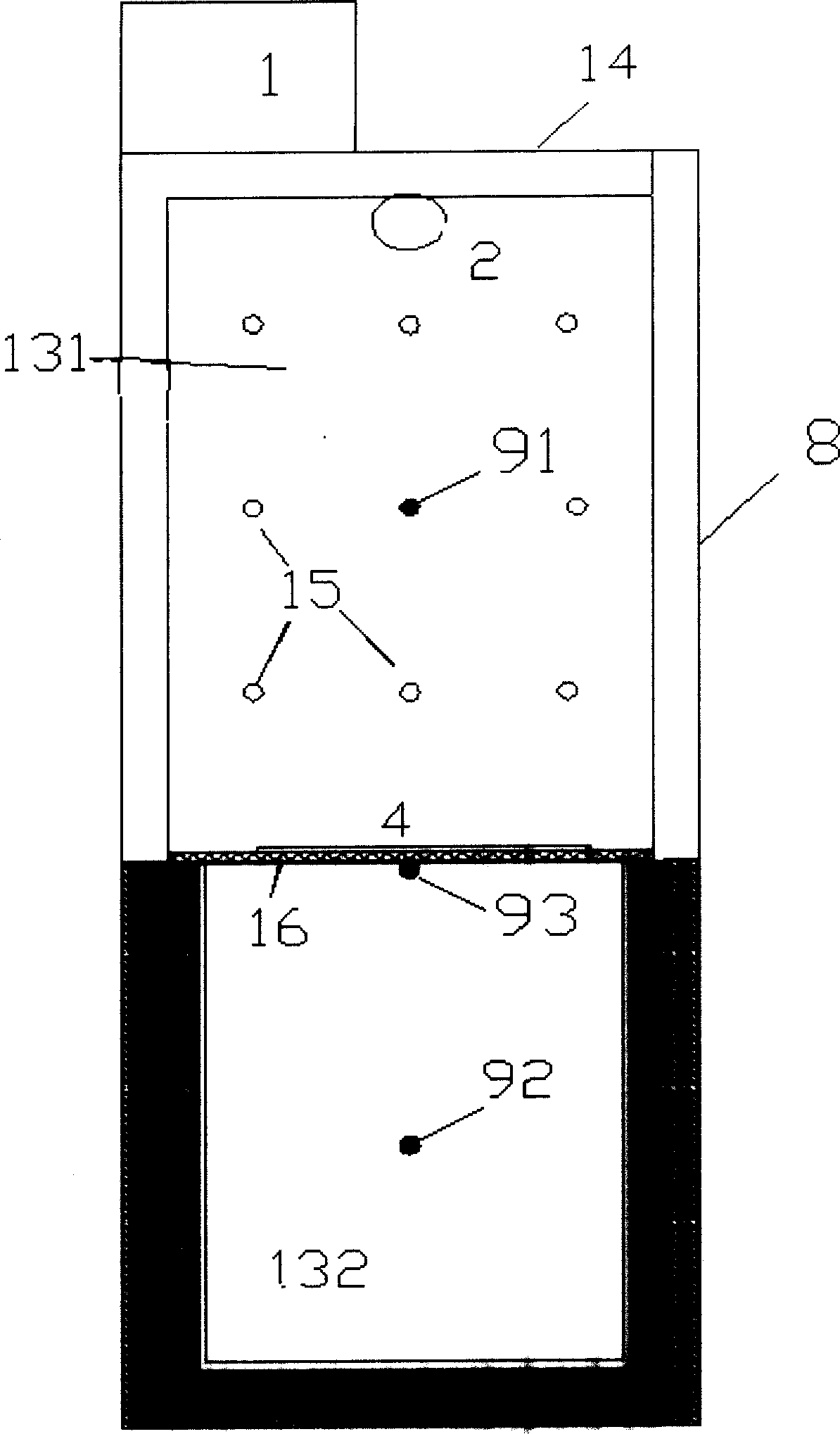

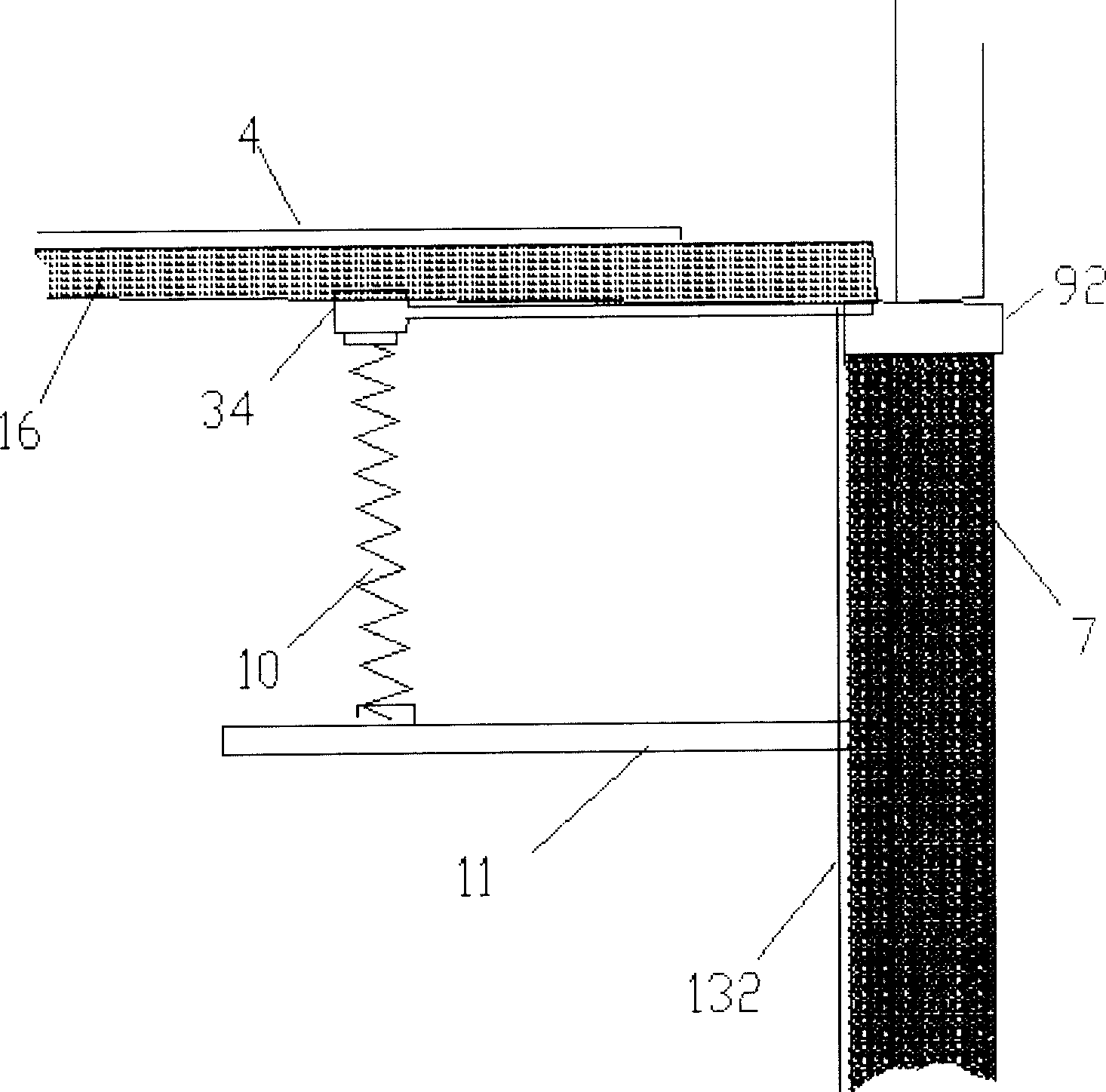

[0033] 1). Preparation of test sample plate

[0034] The detection device and detection method of the present invention are applicable to various building heat insulation materials, including plate materials, powder paste materials and coatings. There are different preparation methods for the test sample boards of different building insulation materials:

[0035] (1) Preparation of the test sample plate of the plate-like material: cut the plate-like material into a rectangular test sample plate, the thickness H of which is 3-100 mm. The size and thickness of the rectangular plane of the test sample plate for plate-like materials depend on the size design of the inner cavity of the box body 5 on the testing device and the material and specification of the plate-like material.

[0036] (2) Preparation of paste-like material test sample boards: Divide paste-like materials 2-3 times through forming, scraping, brushing or spraying on standard carrier boards to make uniform test sa...

Embodiment 1

[0076] Detection of heat insulation effect of heat insulation coating.

[0077] Preparation of sample plates: apply about 50g of paint samples evenly in two times on square flat glass with a weight of 524.7g, 525.3g, and 526.8g, and a size of 300×300×3mm. The mass of the paint after drying is 21.5g, 21.8g, 22.2g. After the first coating was completed, the second coating was performed after the coating was completely dry, and the time interval between the two brushings was 4 hours; at room temperature, the sample plate was naturally dried for 48 hours, and the sample plate to be tested was prepared.

[0078] Sample plate test: place the sample plate to be tested on the sample plate holder of the detection device, with the coating surface of the sample plate facing up; close the door of the device, turn on the power of the temperature inspection instrument, record the original temperature, turn on the infrared lamp (100W), and at the same time Timing, start to regularly record ...

Embodiment 2

[0081] Detection of putty heat insulation effect.

[0082] Prepare the sample plate: apply about 100g of putty sample evenly on the square flat glass with a weight of 534.2g, 535.3g, 537.6g and a size of 300×300×3mm in two times, and the mass of the putty after drying is 48.5g, 50.2g, 51.8g. After scraping the putty for the first time, wait for the second time to scrape the putty after it is completely dry, and the time interval between the two brushings should not be less than 6 hours; at room temperature, after the sample board is naturally dried for 48 hours, the sample board to be tested is prepared.

[0083] Sample plate test: place the sample plate of the test piece on the sample plate holder of the testing device, with the coating surface of the coated sample facing up; close the door of the device, turn on the power of the paperless recorder, record the original temperature, and turn on the infrared lamp (100W ), at the same time, start to regularly record the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com