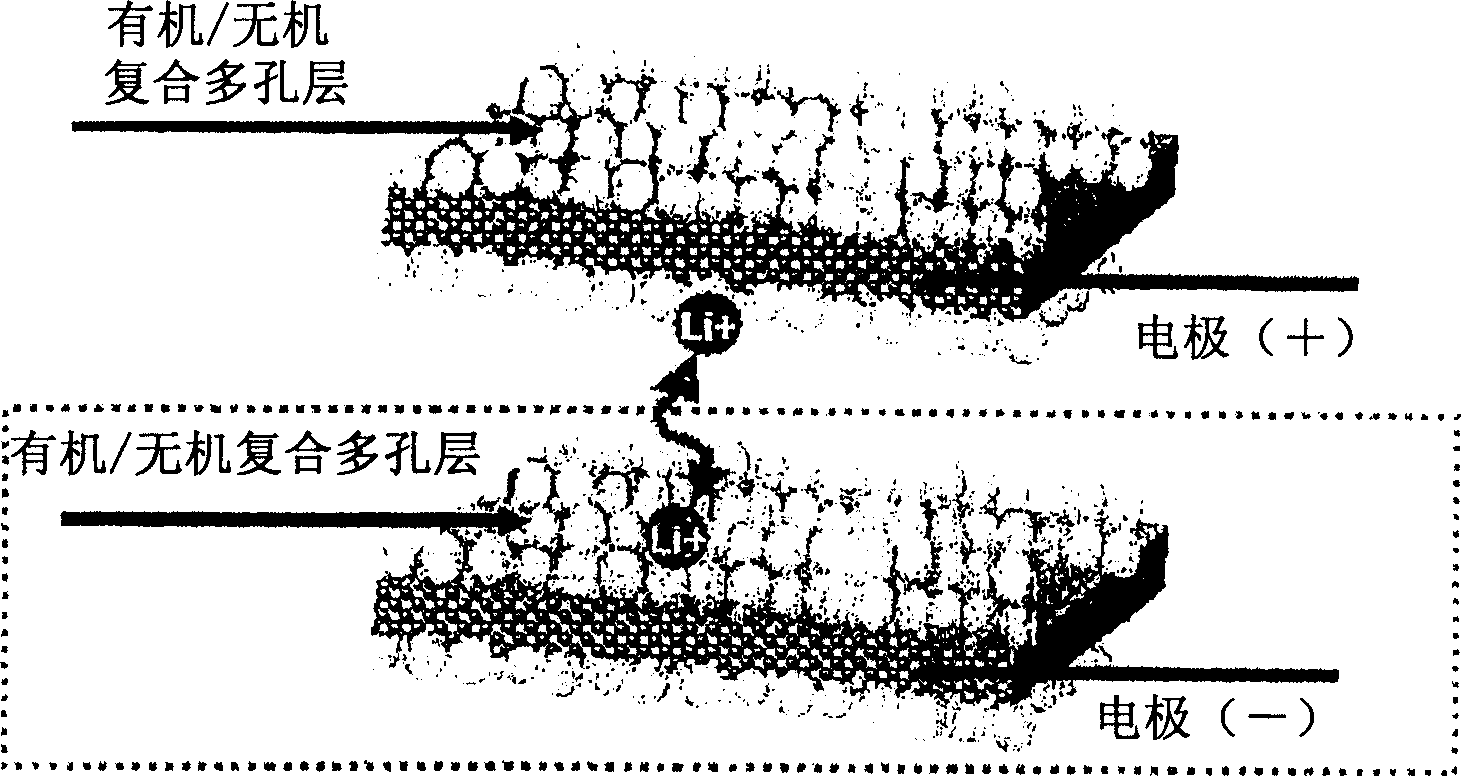

Organic/inorganic composite porous layer-coated electrode and electrochemical device comprising the same

An inorganic composite and electrochemical technology, applied in the field of electrodes, can solve the problems of inability to provide mechanical properties, easy destruction of chemical structure, uneven selection of calorific value time, etc., to achieve the effects of improving mechanical properties, firm physical bonding, and preventing short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Example 1. Preparation of an electrode coated with an organic / inorganic composite porous coating and a lithium secondary battery comprising the electrode

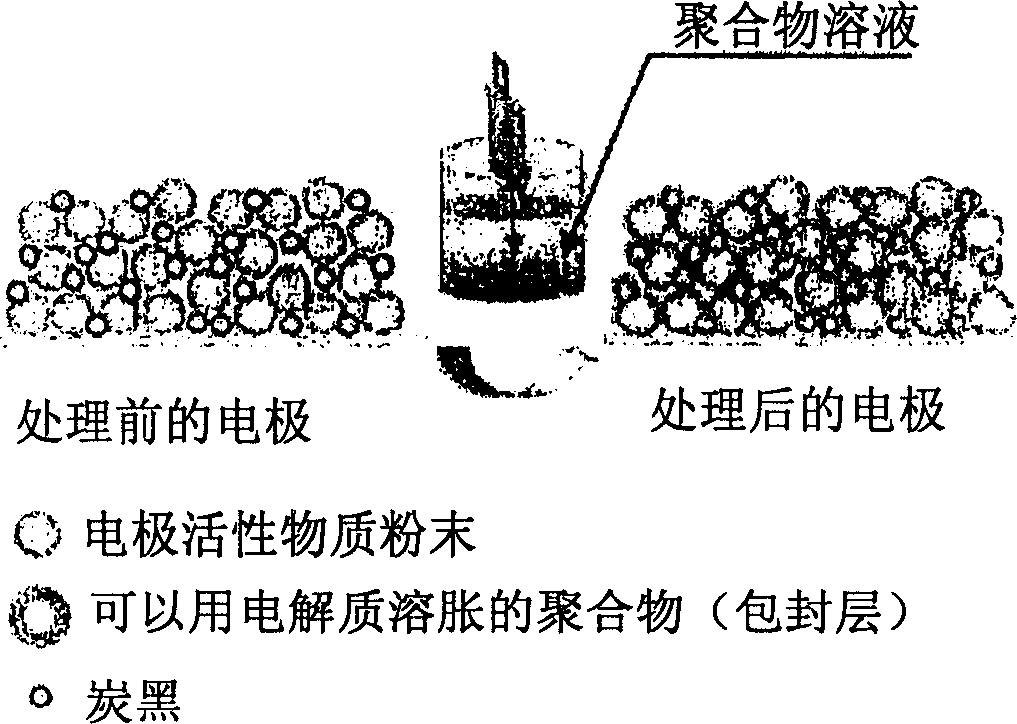

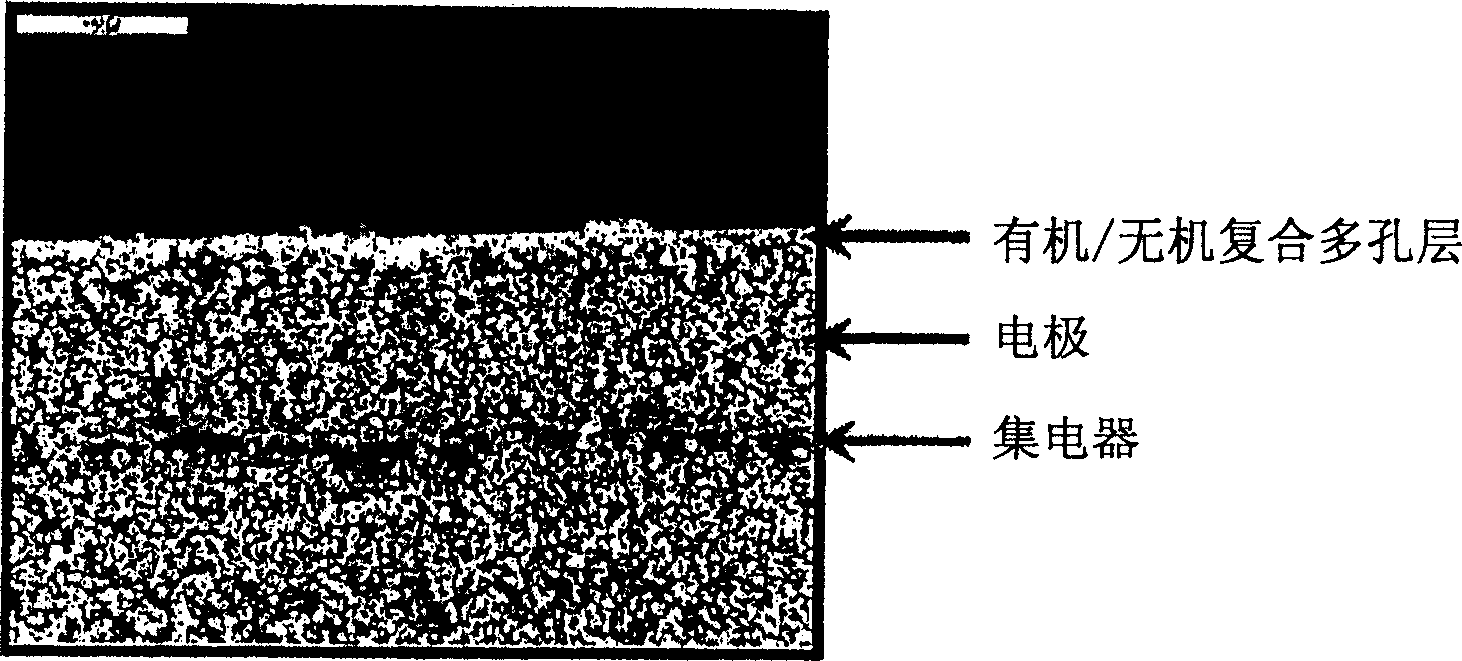

[0094] 1-1. Electrode with organic / inorganic composite porous coating (PVdF-CTFE / Al 2 o 3 )

[0095] (Preparation of anode)

[0096] With N-methyl-2-pyrrolidone (NMP) as solvent, add 96wt% carbon powder as anode active material, 3wt% PVDF (polyvinylidene fluoride) as binder and 1wt% carbon black as conductive agent , forming an anode mixed slurry. The slurry was coated on a 10 μm thick copper foil as an anode current collector, and then dried to form an anode. The anode is then rolled.

[0097] (Preparation of cathode)

[0098] With N-methyl-2-pyrrolidone (NMP) as solvent, 92wt% lithium cobalt composite oxide (LiCoO 2 ), 4wt% carbon black as a conductive agent and 4wt% PVDF (polyvinylidene fluoride) as a binder to form a cathode slurry. The slurry was coated on a 20 μm thick aluminum foil as a cathode current...

Embodiment 2

[0104] In addition to using BaTiO3 powder instead of alumina (Al 2 o 3 ) powder as the inorganic particle in the coating material of electrode surface, repeat embodiment 1 to provide to have organic / inorganic composite porous coating (PVdF-CTFE / BaTiO 3 ) electrodes and lithium secondary batteries.

Embodiment 3

[0106] In addition to replacing alumina (Al 2 o 3 ) powder as the inorganic particle in the coating material of electrode surface, repeat embodiment 1 to provide electrode and lithium secondary battery with organic / inorganic composite porous coating (PVdF-CTFE / PMN-PT).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com