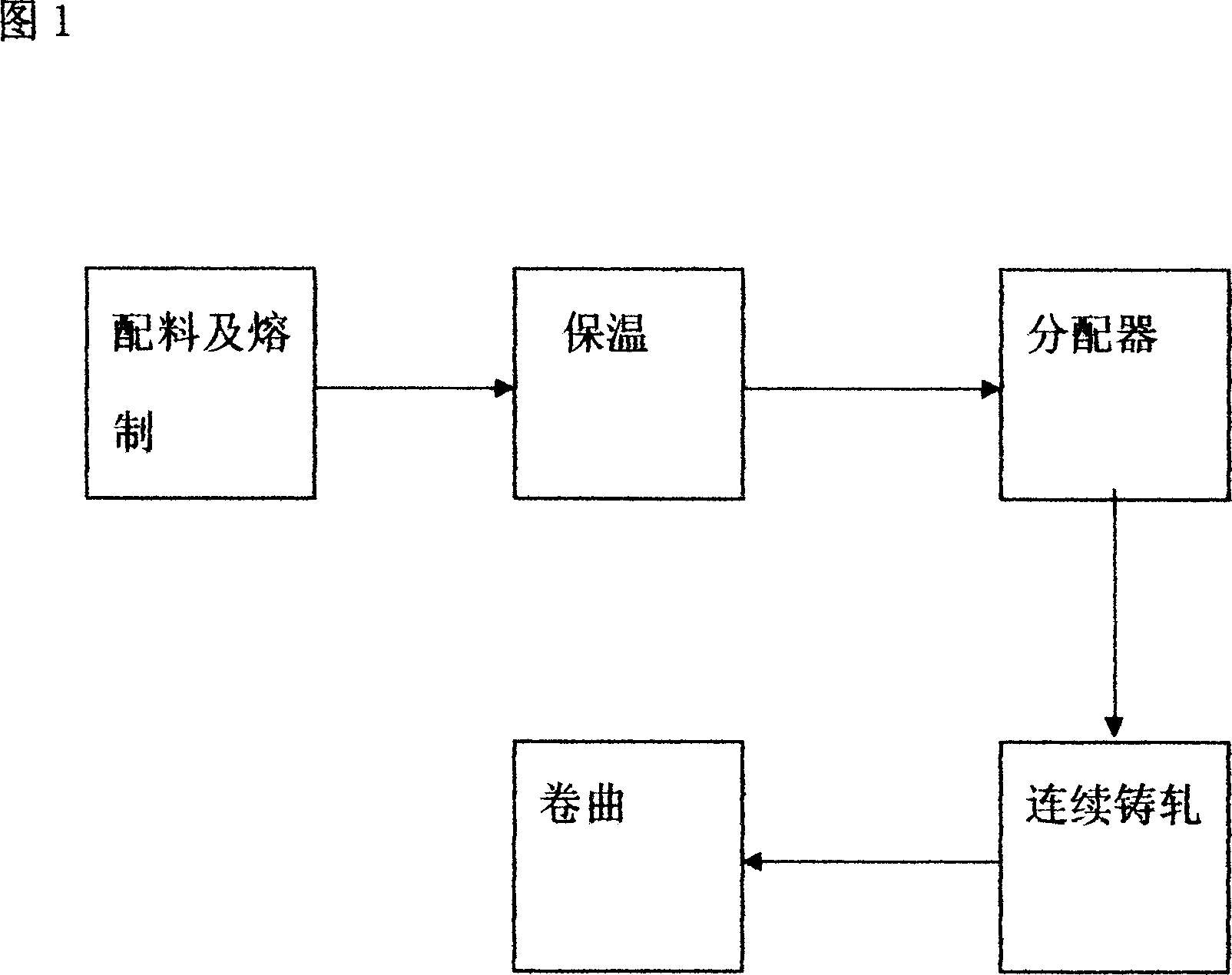

Technological process for continuous casting and rolling low-magnalium thin plate and band

A processing method and technology of aluminum alloy, applied in the direction of metal rolling, tension/pressure control, roll speed control, etc., can solve the problems of high metal loss, high cost, long process, etc., achieve less metal loss, improve yield, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Combined with the accompanying drawings, the production of a low-magnesium aluminum alloy sheet strip casting and rolling coil with a specification size of 5.0×1000mm is illustrated as an example. The steps are:

[0020] 1 Batching and melting: First, weigh them separately according to the weight ratio, put them into the melting furnace until the ingredients are completely melted, melting temperature: 710°C.

[0021] 2 heat preservation: pour from the smelting furnace to the heat preservation furnace for heat preservation, the temperature of the heat preservation furnace is 730 ℃.

[0022] 3 Front box: Use siphon or quantitative pump to send the solution from the holding furnace into the front box. The discharge temperature of the front box is 710°C, and the front box is installed in conjunction with the distributor, and communicates through the diversion hole between them.

[0023] 4 Distributor: Through the diversion holes connected with the front box, through several...

Embodiment 2

[0027] Combined with the accompanying drawings, the production of a low-magnesium aluminum alloy thin strip cast-rolled coil with a specification size of 10.0×1000mm is illustrated as an example. The steps are:

[0028] 1 Batching and melting: First, weigh them separately according to the weight ratio, and put them into the melting furnace until the ingredients are completely melted; melting temperature: 780°C.

[0029] 2 heat preservation: pour from the smelting furnace to the heat preservation furnace for heat preservation, the temperature of the heat preservation furnace is 750 ℃.

[0030] 3 Front box: The solution is sent from the holding furnace to the front box by means of siphon or quantitative pump. The discharge temperature of the front box is 730°C, and the front box is installed in conjunction with the distributor, and communicated through the diversion hole between them.

[0031] 4 Distributor: The distributor is composed of a front box and a distributor; the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com