Preparation method of ferro-electricity/ferro-magnetism multiple phase ceramic

A composite ceramic and ferromagnetic technology, which is applied in the field of ferroelectric/ferromagnetic composite phase ceramics, can solve the problems of performance degradation, small ferromagnetism, and no theoretical research on seepage, and achieve high magnetic permeability, low cost, and high magnetoelectric coefficient. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

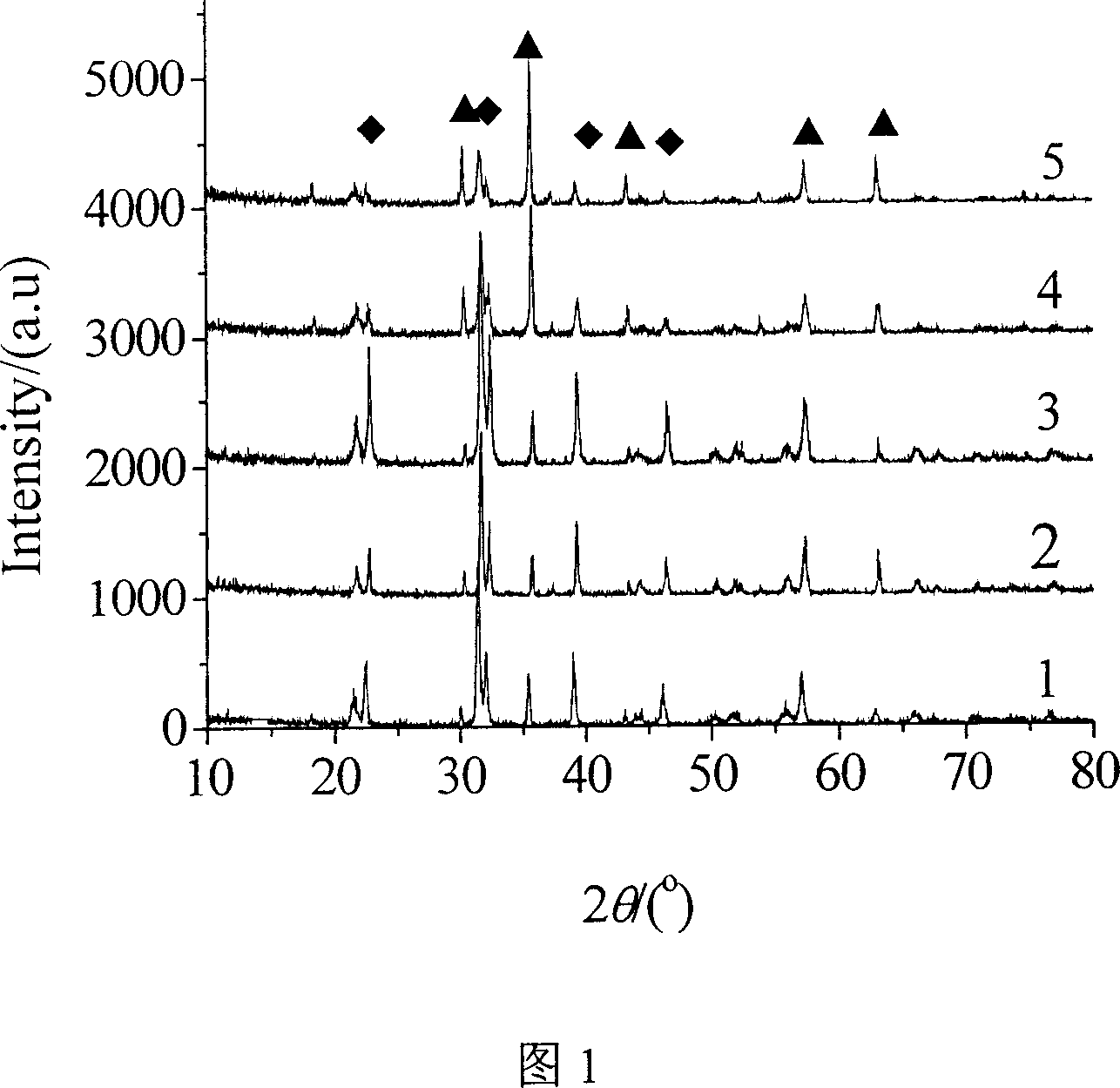

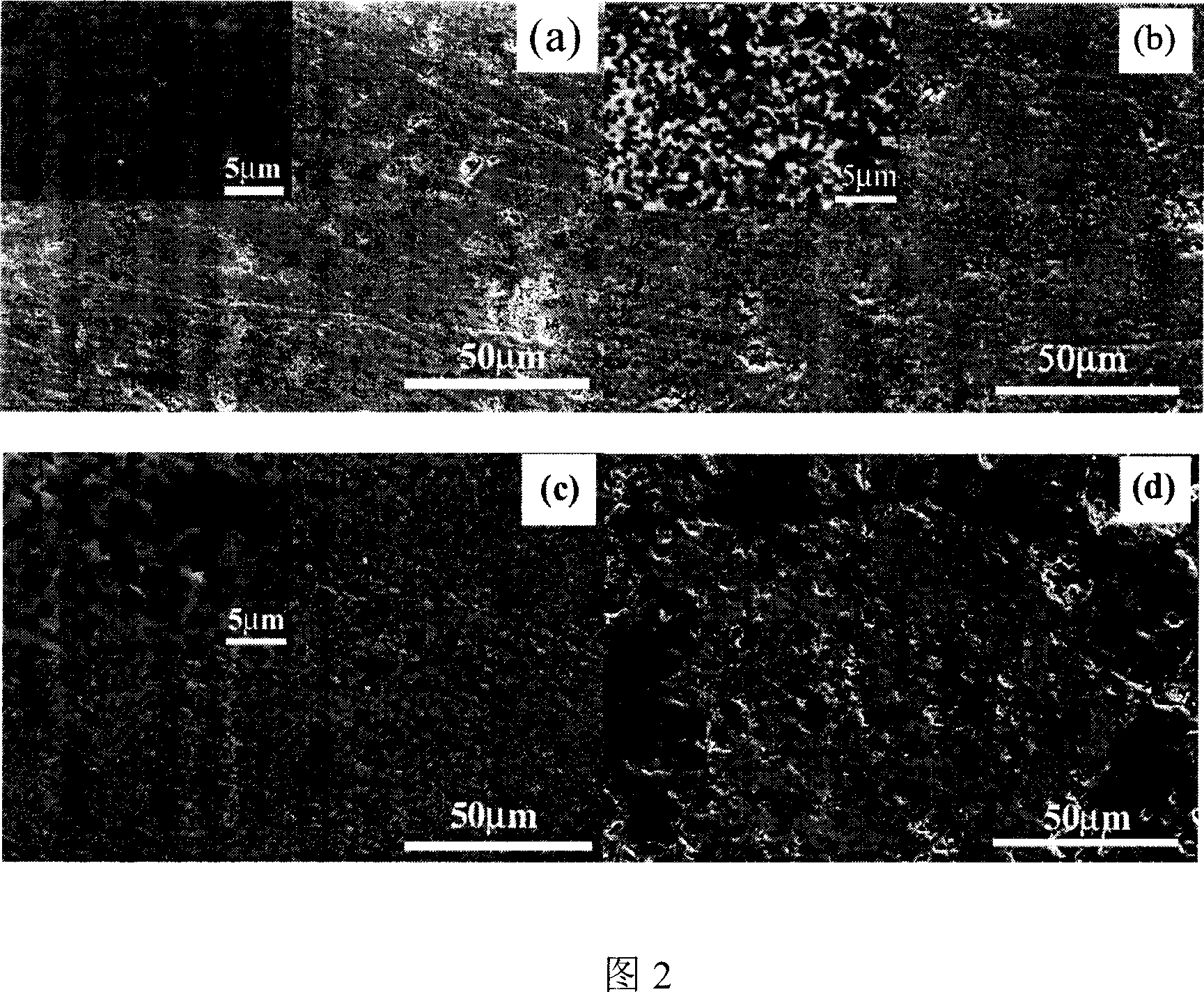

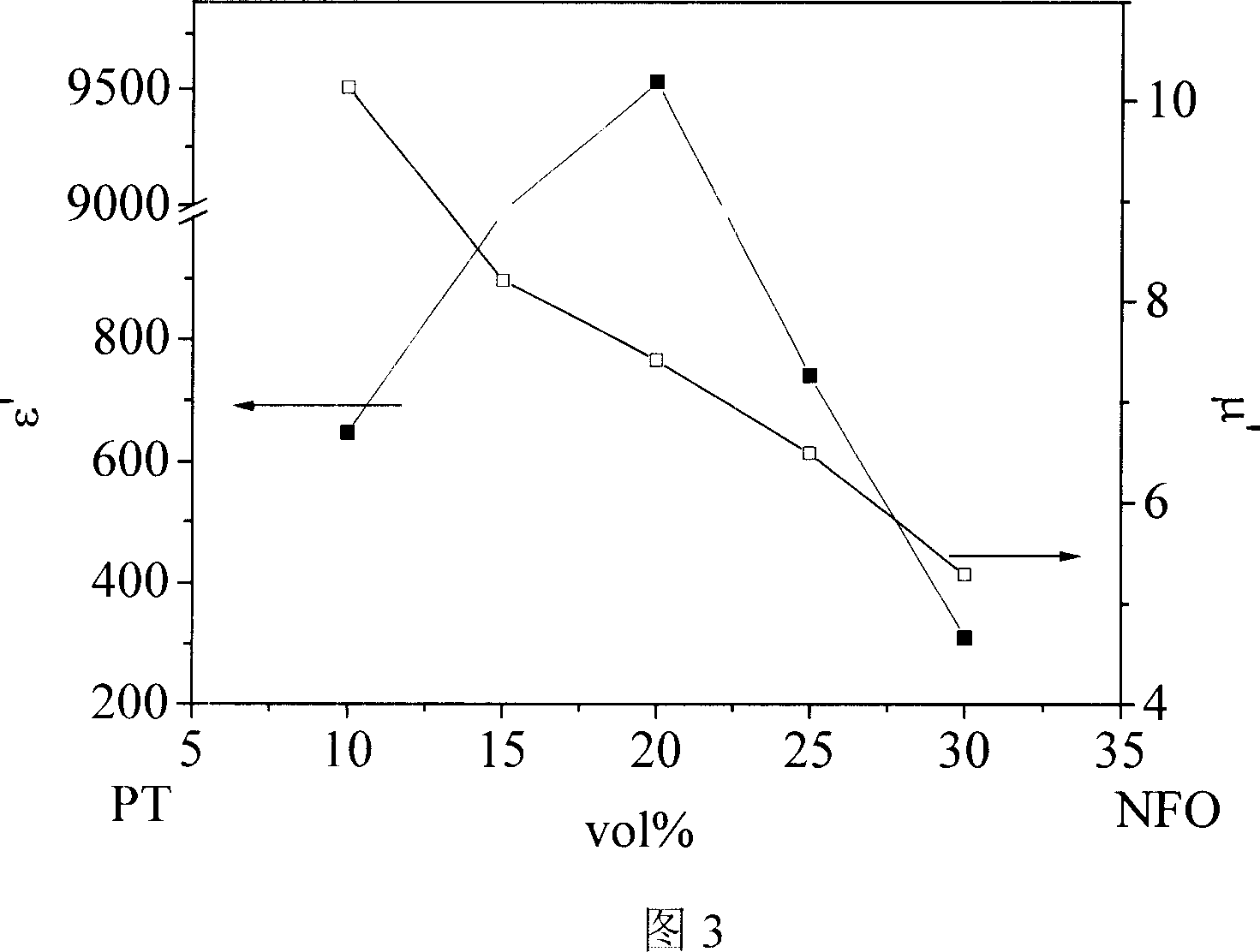

[0025] Lead acetate is dissolved in acetic acid, butyl titanate, nickel acetate and iron nitrate are dissolved in ethylene glycol methyl ether respectively, and the concentrations are: 5mol / L, 5mol / L, 0.1mol / L and 0.1mol / L respectively. Then the four solutions were mixed to obtain the Pb-Ti-Ni-Fe precursor sol, and the molar concentrations of the four components were: 0.06mol / L, 0.06mol / L, 0.14mol / L and 0.28mol / L. The precursor sol was dried at 90°C for 60h, and then pretreated at 650°C for 2h to obtain a PbTiO-containing 3 and NiFe 2 o 4 The two-phase ceramic precursor is pressed into a ring under a pressure of 6MPa, and heat-treated at 1200°C for 2h to obtain PbTiO 3 and NiFe 2 o 4 Two-phase composite ceramics. The composition of the multiphase ceramics is shown in the accompanying drawing 1 curve 1, as can be seen from the figure, the ceramics generated under the conditions of this example are PbTiO 3 、NiFe 2 o 4 two phases. Its morphology is shown in Figure 2(a). ...

Embodiment 2

[0027] Lead acetate is soluble in acetic acid, butyl titanate, nickel acetate and ferric nitrate are respectively soluble in ethylene glycol methyl ether, the concentrations are: 4mol / L, 4mol / L, 0.2mol / L and 0.2mol / L respectively. Then the four solutions were mixed to obtain the Pb-Ti-Ni-Fe precursor sol, and the molar concentrations of the four components were: 0.05mol / L, 0.05mol / L, 0.15mol / L and 0.30mol / L. The precursor sol was dried at 100°C for 48h, and then pretreated at 800°C for 1h to obtain 3 and NiFe 2 o 4 Two-phase and partially amorphous ceramic precursors are pressed into a ring under a pressure of 5 MPa and heat-treated at 1100 ° C for 2.5 h to obtain PbTiO 3 and NiFe 2 o 4 Two-phase composite ceramics. The composition of multiphase ceramics is shown in Figure 1, curve 2, as can be seen from the figure, the ceramics generated under the conditions of this example are PbTiO 3 、NiFe 2 o 4two phases. Its morphology is shown in accompanying drawing 2(b). It ca...

Embodiment 3

[0029] Lead acetate is dissolved in acetic acid, butyl titanate, nickel acetate and iron nitrate are dissolved in ethylene glycol methyl ether respectively, and the concentrations are: 3mol / L, 3mol / L, 0.3mol / L and 0.3mol / L respectively. Then the four solutions were mixed to obtain the Pb-Ti-Ni-Fe precursor sol, and the molar concentrations of the four components were: 0.04mol / L, 0.04mol / L, 0.16mol / L and 0.32mol / L. Dry the precursor sol at 110°C for 30h, and then pretreat it at 550°C for 1.5h to obtain a ceramic precursor that is entirely amorphous, press it into a ring shape under a pressure of 4MPa, and heat treat it at 1150°C for 2h. Get PbTiO 3 and NiFe 2 o 4 Two-phase composite ceramics. The composition of the multiphase ceramics is shown in the curve 3 of the accompanying drawing 1, as can be seen from the figure, the ceramics generated under the conditions of this example are PbTiO 3 、NiFe 2 o 4 two phases. Its morphology is shown in accompanying drawing 2(c). It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com