Method of preparing polythiophene or derivative thereof-multiwall carbon nano-tube composite material

A technology for multi-walled carbon nanotubes and composite materials, which is applied in the field of preparing conductive polymer-carbon nanotube composite materials, can solve the problems of insolubility of composite materials, and the agglomeration of carbon nanotubes is not easy to disperse, and achieves the effect of preventing agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

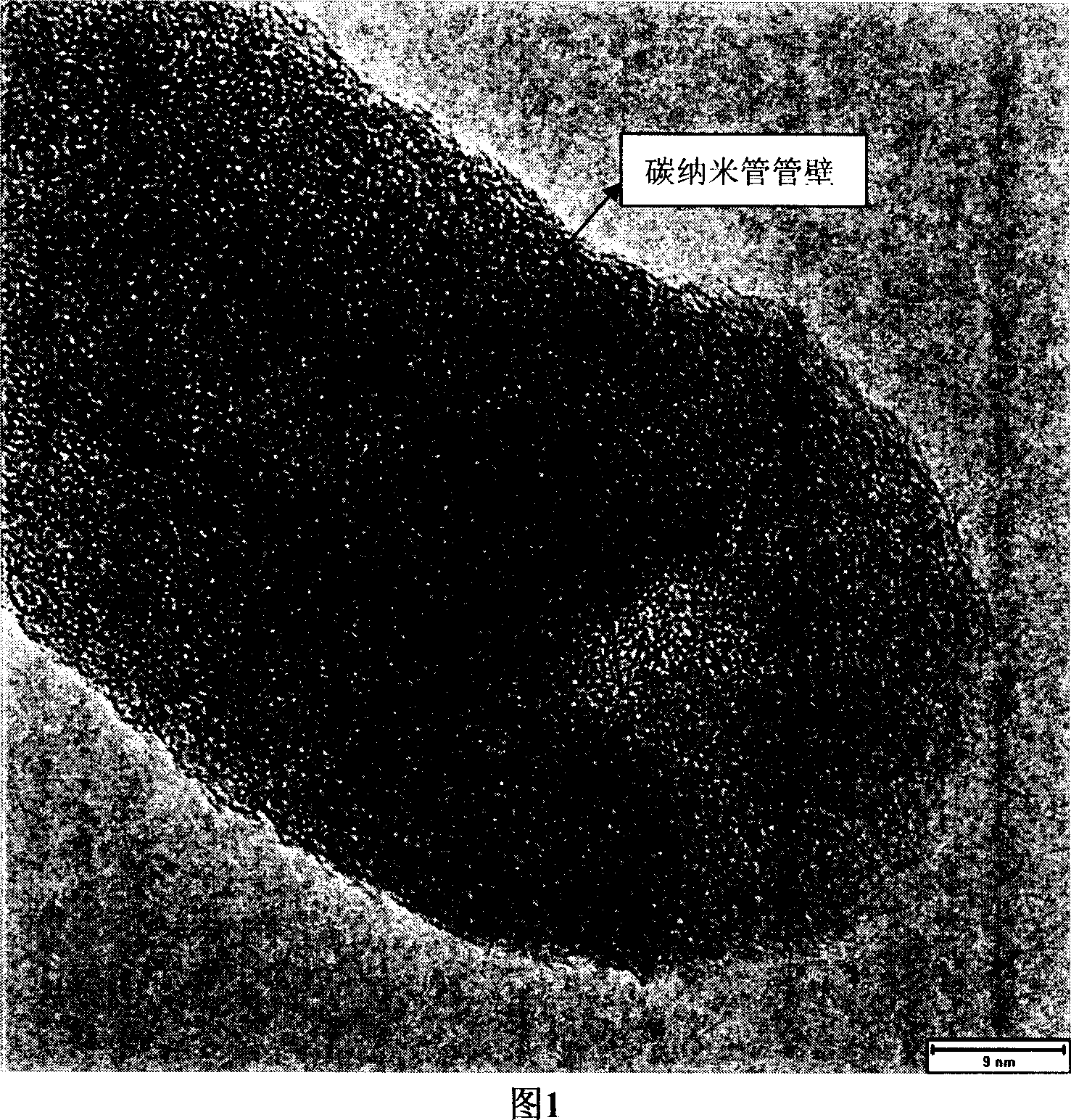

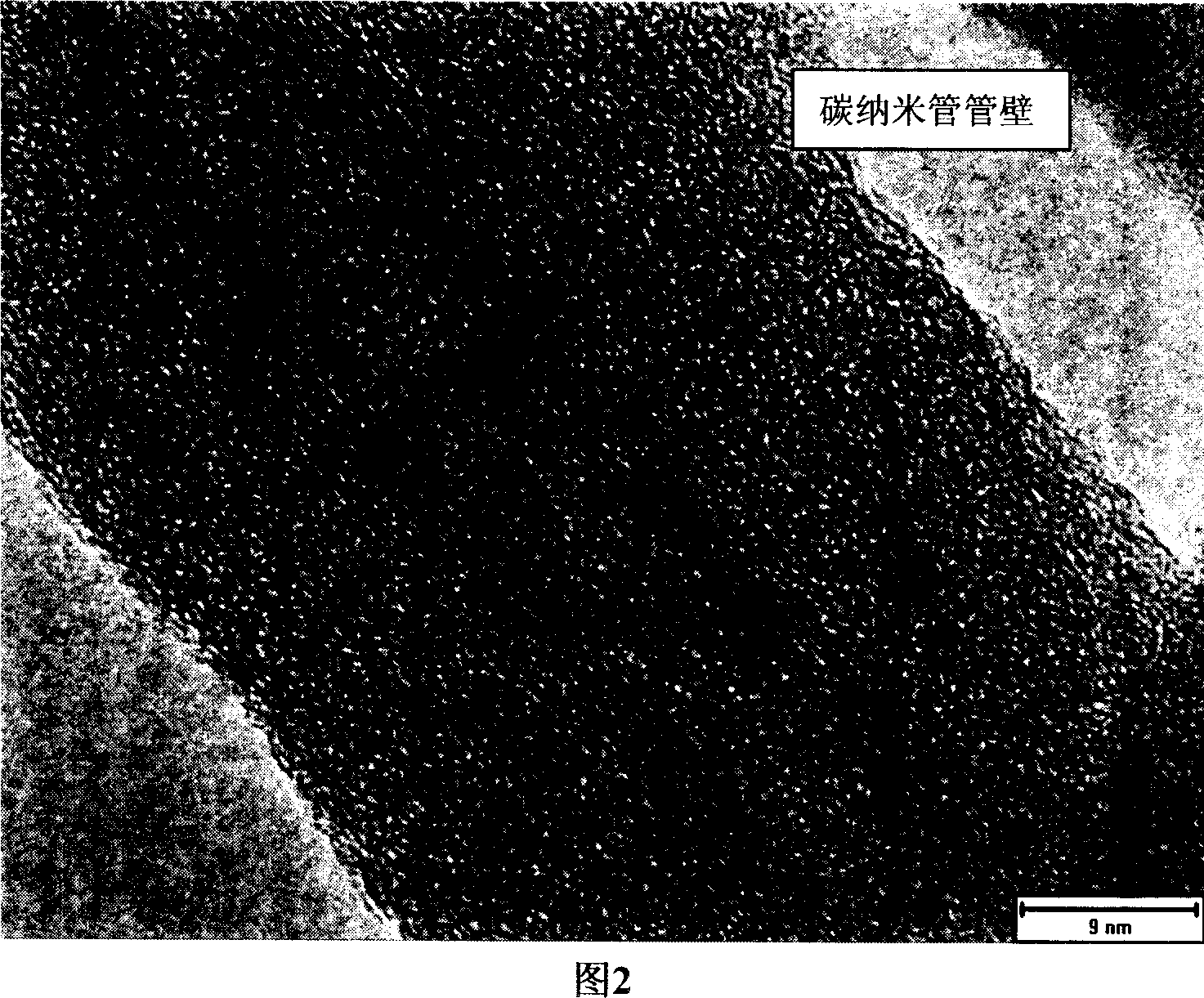

[0028] Preparation steps of polythiophene-multi-walled carbon nanotube composites:

[0029] Step 1, processing multi-walled carbon nanotubes:

[0030] (1) At 80°C, 1.5g of multi-walled carbon nanotubes were mixed with 90ml of 63% HNO 3 Heat under reflux for 4 hours, filter with suction, and repeatedly wash with distilled water until the filtrate becomes colorless;

[0031] (2) adding the multi-walled carbon nanotubes treated in step (1) to a mixed solution of 20 ml distilled water, 100 ml n-heptane and 10 g oleic acid, ultrasonically dispersing and mixing evenly, adding 10 ml 98% sulfuric acid, and adding 10 ml of 98% sulfuric acid at 80° C. , and continue to heat under reflux for 1 hour.

[0032] (3) The mixture of step (2) is liquid-separated, the water phase is removed, and the oil phase is repeatedly washed with distilled water until the water phase becomes colorless, that is, the water phase no longer contains multi-walled carbon nanotubes and detects no SO. 4 2+ unti...

Embodiment 2

[0041] The preparation steps of poly(3-thiophene methyl acetate)-multi-walled carbon nanotube composite material:

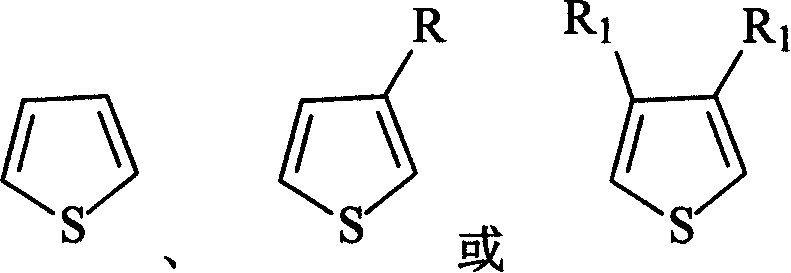

[0042] The monomer used is 3-thiophene methyl acetate, and its structural formula is as follows:

[0043]

[0044] The amount of initiator anhydrous ferric chloride is 4.12g; others are the same as in Example 1.

[0045] After analysis, the multi-walled carbon nanotubes were coated with poly(3-thiophene methyl acetate) to form a core-shell nanowire structure with the multi-walled carbon nanotubes as the core and the polymer as the shell. The product is insoluble in methanol and water, but soluble in chloroform, benzene and toluene.

Embodiment 3

[0047] Preparation steps of poly(3-methoxythiophene)-multi-walled carbon nanotube composites:

[0048] The monomer used is 3-methoxythiophene, and its structural formula is as follows:

[0049]

[0050] The amount of initiator anhydrous ferric chloride is 5.70g; others are the same as in Example 1.

[0051] After analysis, the multi-walled carbon nanotubes were coated with poly(3-methoxythiophene) to form a core-shell nanowire structure with the multi-walled carbon nanotubes as the core and the polymer as the shell. The product is soluble in dimethyl disulfone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com