Fast forming laser diode energy source and device for same

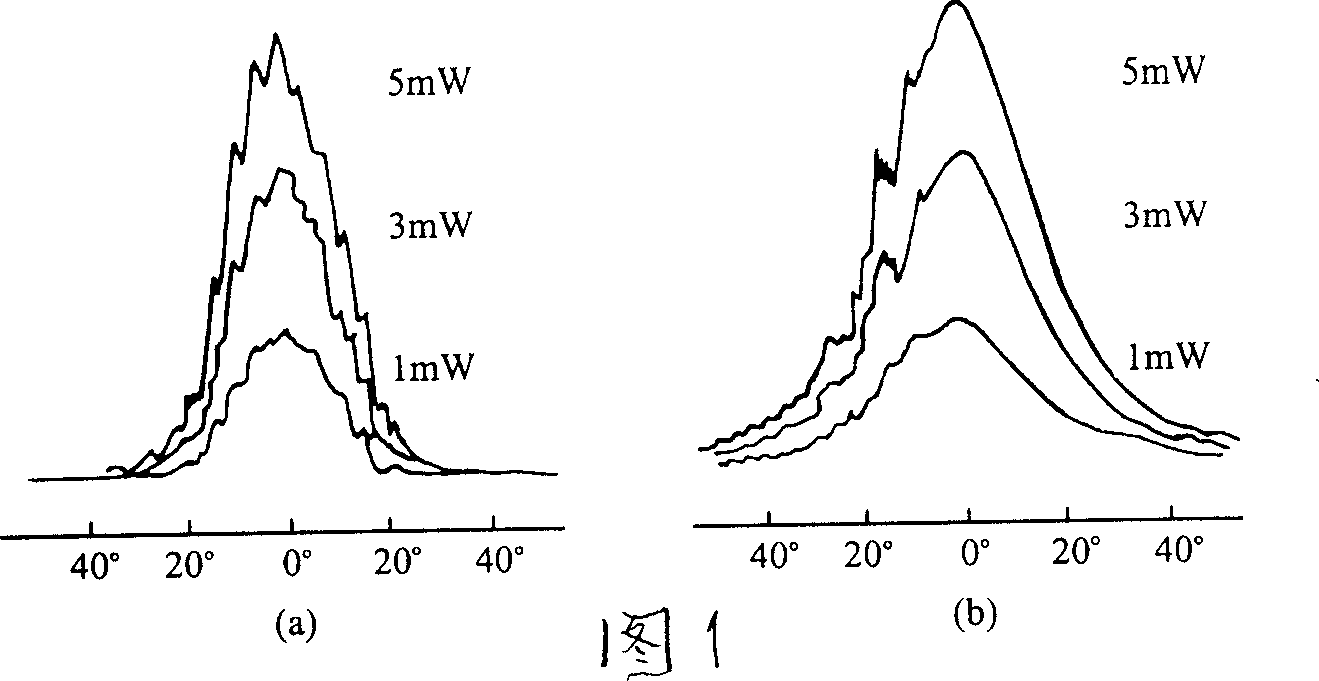

A technology of laser diodes and forming equipment, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of large volume, fixed spectrum and poor reliability of gas lasers, and achieve the effects of low price, reduced system cost and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

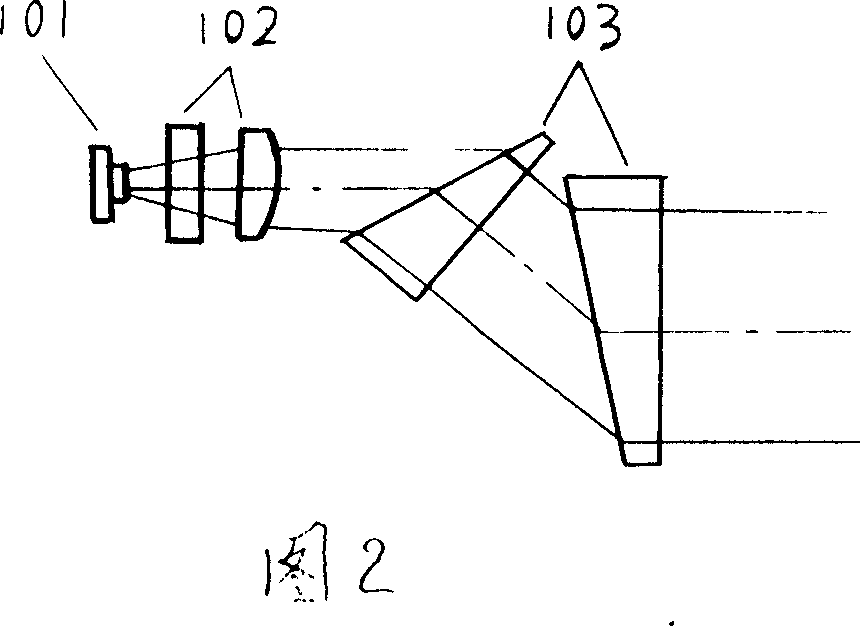

[0036] The specific embodiment of the present invention (utility model) will be described below in conjunction with the accompanying drawings.

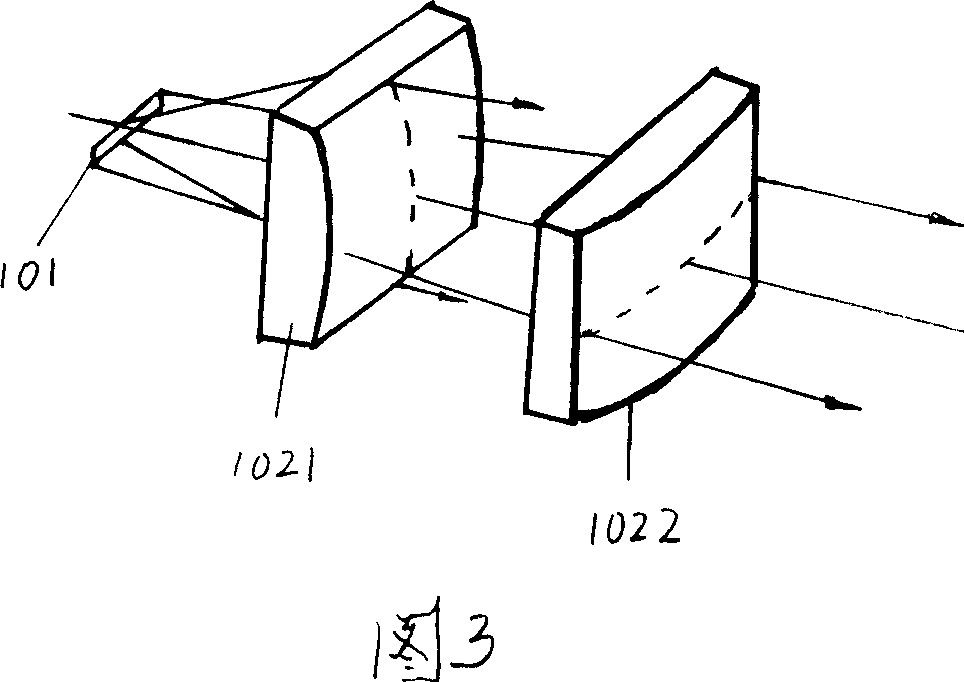

[0037] As shown in Figure 2, it is a laser diode energy source for rapid prototyping; the light source is a laser diode LD101, and the astigmatic beam output by the laser diode LD light source is collimated by a cylindrical lens group 102 to become a parallel beam, and then the beam expander 103 expands the slow axis The parallel beam is expanded, and the astigmatic beam output by the laser diode light source is collimated and expanded into a circular parallel beam.

[0038] Wherein: the cylindrical mirror group includes a fast-axis collimating cylindrical mirror 1021 and a slow-axis collimating cylindrical mirror 1022, and the bus lines of the fast-axis collimating cylindrical mirror and the slow-axis collimating cylindrical mirror are perpendicular to each other. In the slow-axis plane of the diode LD light source, the fast-axis col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com