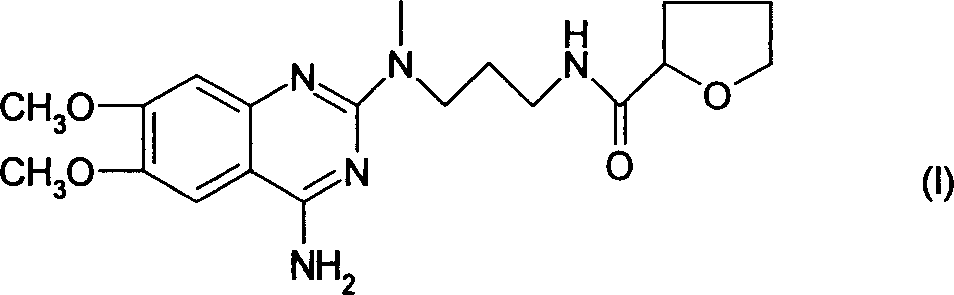

Method for preparing alfuzosin

An alfuzosin and quinazoline-based technology, which is applied in the field of preparation of alfuzosin, can solve the problems of many by-products, harsh conditions, long reaction steps, etc., and achieves improved product yield and quality, and mild reaction conditions. , the effect of simplifying the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

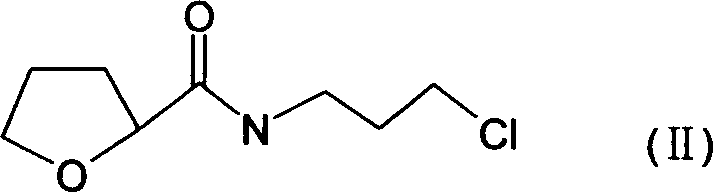

[0026] a. Preparation of N-3-chloropropyl-2-tetrahydrofuran carboxamide (II)

[0027] In a 500mL three-necked flask, add the compound 2-tetrahydrofuroyl chloride (26.9g, 0.2mol), triethylamine (30.3g, 0.3mol), and 180mL of dichloromethane, stir and mix, and cool the mixture to 0°C to 5°C. Keeping the reaction temperature below 10°C, a solution of 3-chloropropylamine (21.11 g, 0.2 mol) and 50 mL of dichloromethane was added dropwise with stirring. After the addition was complete, the reaction was stirred at room temperature overnight. The solvent was distilled off under reduced pressure, and the resulting residue was extracted three times with 300 mL of chloroform. The chloroform extract was washed twice with 200 mL of water, twice with 200 mL of saturated brine, and dried over anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain 4-(4-chlorobutyl)-1-(2,3-dichlorophenyl)piperazine (II). Yield: 79.8%.

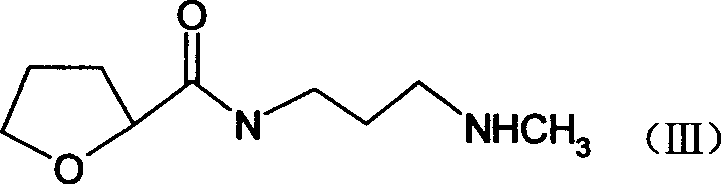

[0028] b. Preparation of N-3-methylami...

Embodiment 2

[0033] a. Preparation of N-3-chloropropyl-2-tetrahydrofuran carboxamide (II)

[0034] In a 500mL three-necked flask, add the compound 2-tetrahydrofuroyl chloride (26.9g, 0.2mol), pyridine (23.7g, 0.3mol), and 180mL of chloroform, stir and mix, and cool the mixture to 0°C to 5°C to keep the reaction With the temperature below 15°C, a solution of 3-chloropropylamine (21.11 g, 0.2 mol) and 50 mL of chloroform was added dropwise with stirring. After the addition was complete, the reaction was stirred overnight at room temperature. The solvent was distilled off under reduced pressure, and the resulting residue was extracted three times with 300 mL of chloroform. The chloroform extract was washed twice with 200 mL of water, twice with 200 mL of saturated brine, and dried over anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain 4-(4-chlorobutyl)-1-(2,3-dichlorophenyl)piperazine (II). Yield: 75.3%, mp.

[0035] b. Preparation of N-3-methylaminop...

Embodiment 3

[0040] a. Preparation of N-3-chloropropyl-2-tetrahydrofuran carboxamide (II)

[0041] In a 500mL three-necked flask, add compound 2-tetrahydrofuroyl chloride (26.9g, 0.2mol), pyridine (23.7g, 0.3mol), N,N-dimethylformamide (DMF) 150mL, stir and mix, and cool the mixture To 0 ℃ ~ 5 ℃, keep the reaction temperature below 15 ℃, dropwise add a solution of 3-chloropropylamine (21.11g, 0.2mol) and N,N-dimethylformamide (DMF) 50mL under stirring, the dropwise addition is complete , 50 ℃ ~ 55 ℃ stirring reaction for 14 hours. The solvent was distilled off under reduced pressure, and the resulting residue was extracted three times with 300 mL of chloroform. The chloroform extract was washed twice with 200 mL of water, twice with 200 mL of saturated brine, and dried over anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain 4-(4-chlorobutyl)-1-(2,3-dichlorophenyl)piperazine (II). Yield: 82.5%, mp.

[0042] b. Preparation of N-3-methylaminopropyl-2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com