Tail gas treatment and reutilization for calcium carbide stove

A technology of calcium carbide furnace tail gas and tail gas, which is applied in separation methods, chemical instruments and methods, ammonia preparation/separation, etc., to achieve low production costs, low prices, and improved dust removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

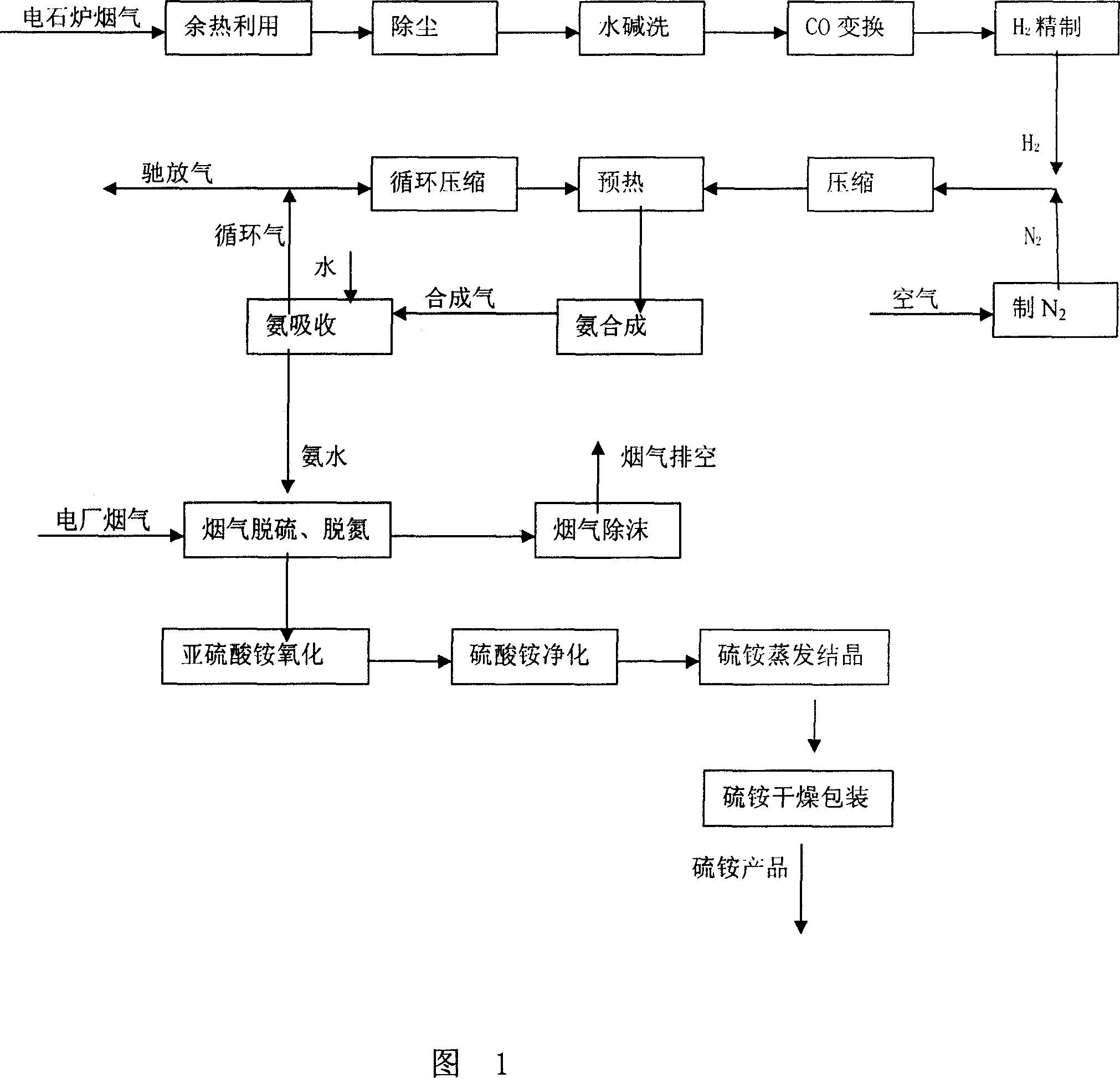

Image

Examples

Embodiment Construction

[0031] 1. The pretreatment process of calcium carbide furnace tail gas, including the cooling, dust removal and purification process of calcium carbide furnace tail gas, among which

[0032] The cooling process refers to sending the tail gas of the calcium carbide furnace into the by-product steam boiler to cool down by the fan. This process can produce 1.3-1.5MPa medium-pressure steam;

[0033] The dust removal process is realized in a multi-tube dust collector;

[0034] The purification process is to use water washing cooling and alkali washing to remove sulfur, that is, the flue gas passes through the water washing tower and alkali washing tower to remove dust particles, tar, CO 2 , sulfur and other impurities, the purified tail gas CO purity is over 90%.

[0035] 2. The tail gas synthesis ammonia process adopts a multi-stage conversion process to convert CO into H 2 , shift gas to remove CO 2 and make H 2 The molecular sieve pressure swing adsorption process is adopted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com