Butylphthalide dripping pill and preparing method

The technology of butylphthalide dropping pills and butylphthalide is applied in the directions of pill delivery, pharmaceutical formulations, medical preparations containing active ingredients, etc. large and other problems, and achieve the effect of overcoming low bioavailability, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

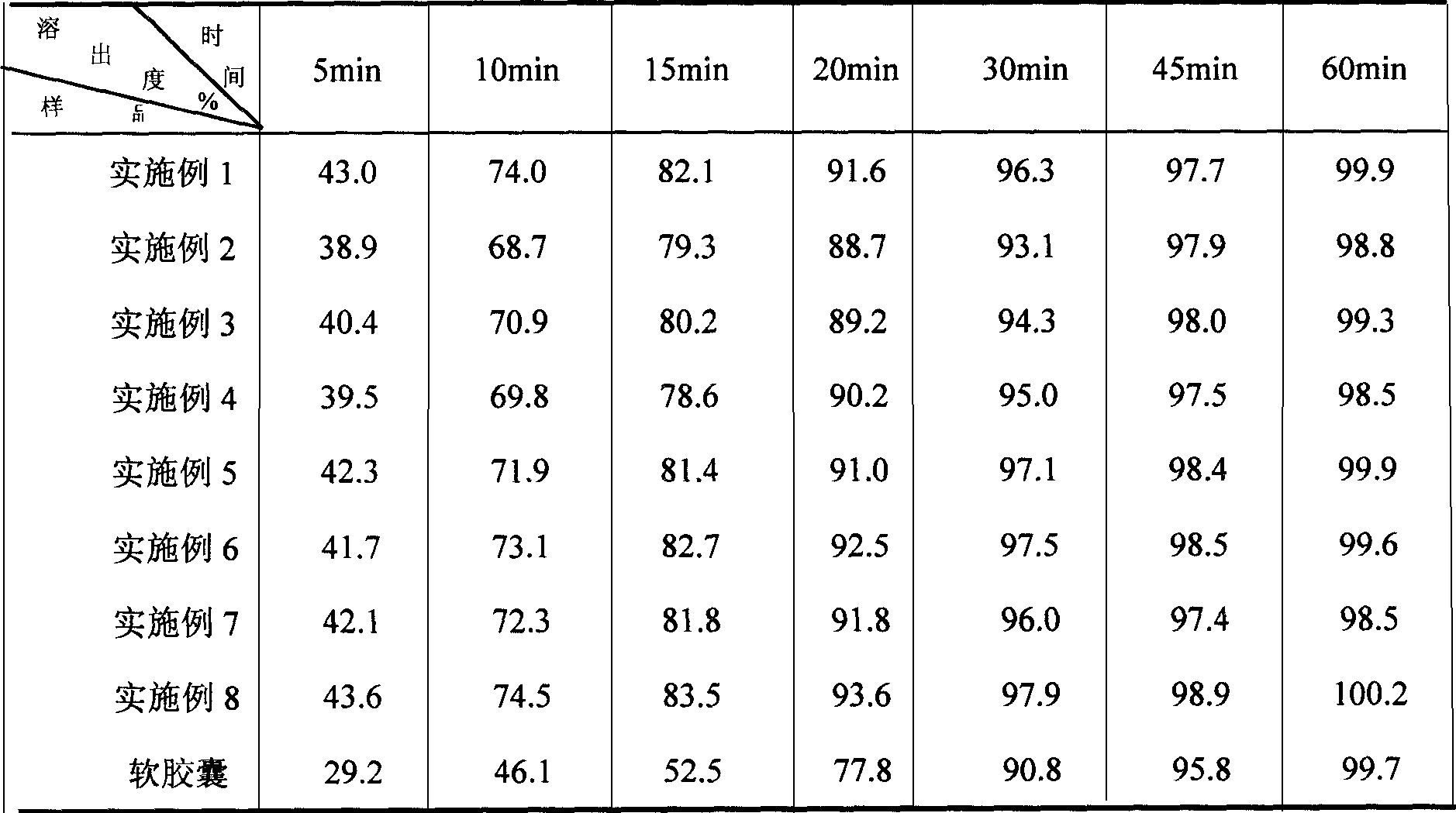

Examples

Embodiment 1

[0032] Butylphthalide 50g 23.3%

[0033] Macrogol 6000 130g 60.4%

[0034] Light micronized silica gel 24g 11.2%

[0035] Crospovidone 4g 1.9%

[0036] Hypromellose 7g 3.2%

[0037] Operation: Weigh butylphthalide, add light differential silica gel and cross-linked povidone, stir well, then add into molten polyethylene glycol 6000 and stir to mix evenly. Drop into pills at a rate of 25-35 drops per minute, shrink into pills by simethicone oil (viscosity: 100 cts) condensate, collect the pills, spin dry, sieve the pills, and coat the pills.

Embodiment 2

[0039] Butylphthalide 50g 15.1%

[0040] Macrogol 4000 200g 60.4%

[0041] Macrogol 20000 40g 12.1%

[0042] Light micronized silica gel 31g 9.4%

[0043] Hydroxypropyl Cellulose 10g 3.0%

[0044] Operation: Weigh butylphthalide, add light differential silica gel and stir evenly, then add into molten polyethylene glycol 4000 and polyethylene glycol 20000, stir and mix evenly, and keep the liquid medicine at 80-90°C for heat preservation. Drop into pills at a rate of 25 to 35 drops per minute, shrink into pills through the liquid paraffin condensate, collect the pills, shake dry, sieve the pills and coat the pills.

Embodiment 3

[0046] Butylphthalide 50g 20.7%

[0047] Macrogol 6000 154g 63.9%

[0048] Poloxamer 5g 2.1%

[0049] Light micronized silica gel 26g 10.8%

[0050] Ethylcellulose 6g 2.5%

[0051] Operation: Weigh butylphthalide, add light differential silica gel and stir evenly, then add molten polyethylene glycol 6000 and poloxamer, stir and mix evenly, and drop the medicine solution at 80-90°C to prepare Pills, the dripping speed is 25-35 drops per minute, shrink into pills by liquid paraffin condensate, collect the dripping pills, shake dry, sieve the pills and then coat the pills.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com