Process for preparing hybridized porous lithium ion cell electrolyte film

A lithium-ion battery and electrolyte membrane technology, which is applied in the field of preparation of polymer electrolytes, can solve problems such as unexplained distribution characteristics of composite electrolyte membranes, achieve good hybridization effects, avoid phase separation, and improve ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Prepare PVDF-HFP solution, weigh 0.5g PVDF-HFP and dissolve 6g in acetone, prepare PVDF-HFP colorless and transparent solution;

[0021] (2) Prepare tetrabutyl titanate solution, weigh 0.1128g tetrabutyl titanate and dissolve in 2.5g n-butanol, prepare tetrabutyl titanate light yellow solution;

[0022] (3) To adjust the pH value of the PVDF-HFP solution, add 0.2ml of 0.1mol / L hydrochloric acid solution dropwise to the PVDF-HFP solution;

[0023] (4) Prepare a composite casting solution. At 20° C., add the above-mentioned light yellow solution of tetrabutyl titanate dropwise to the stirred PVDF-HFP solution to gradually obtain a white mixed solution, raise the temperature to 50° C., and stir at a constant temperature for 6 hours. Obtain a viscous white uniform casting solution;

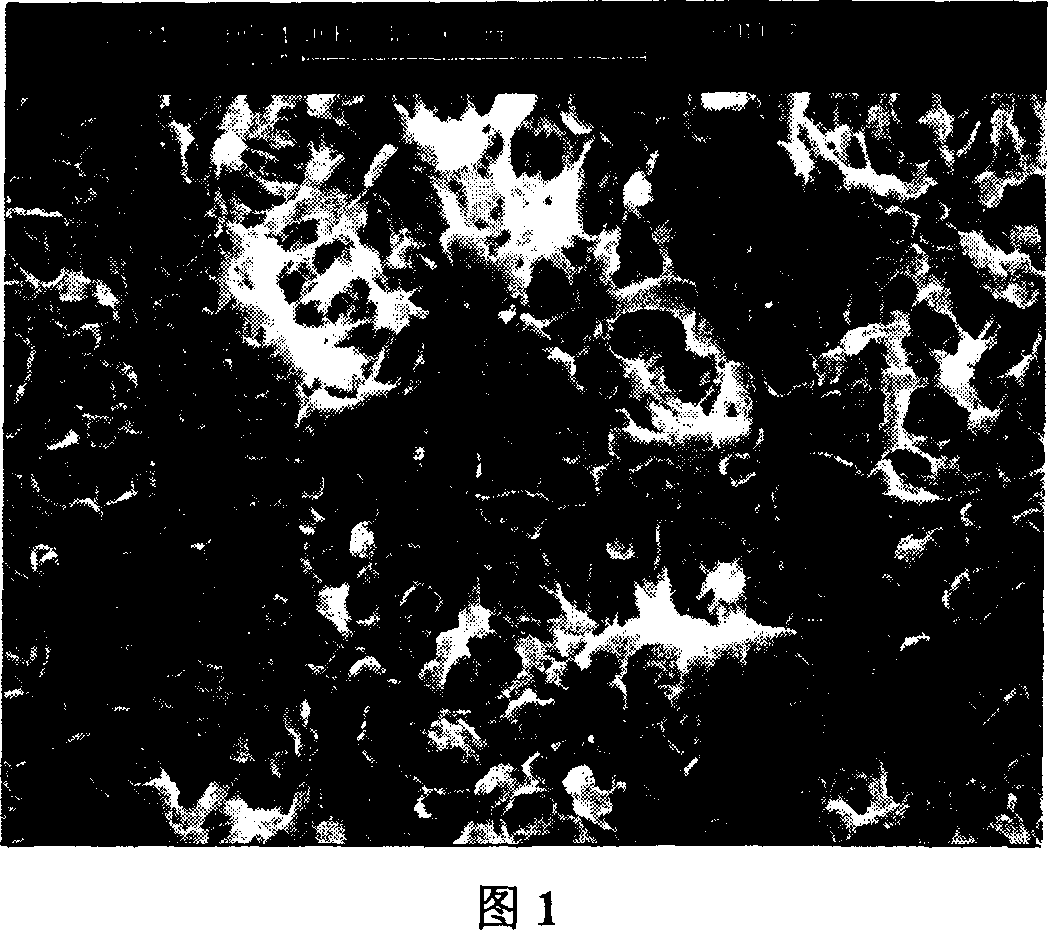

[0024] (5) Forming a film, cooling to 25°C while stirring, casting the white casting liquid in a forming mold, and obtaining TiO after the solvent and non-solvent volatilize 2 / PVDF-HFP h...

Embodiment 2

[0028] (1) Prepare PVDF-HFP solution, take 0.5g PVDF-HFP and dissolve 6g in acetone, prepare PVDF-HFP colorless and transparent solution;

[0029] (2) prepare tetrabutyl titanate solution, weigh 0.1128g tetrabutyl titanate and dissolve in 1.5g n-butanol, prepare tetrabutyl titanate pale yellow solution;

[0030] (3) To adjust the pH value of the PVDF-HFP solution, add 0.2ml of 0.1mol / L hydrochloric acid solution dropwise to the PVDF-HFP solution;

[0031] (4) Prepare a composite casting solution. At 20° C., add the above-mentioned light yellow solution of tetrabutyl titanate dropwise to the stirred PVDF-HFP solution to gradually obtain a white mixed solution, raise the temperature to 60° C., and stir at a constant temperature for 6 hours. Obtain a viscous white uniform casting solution;

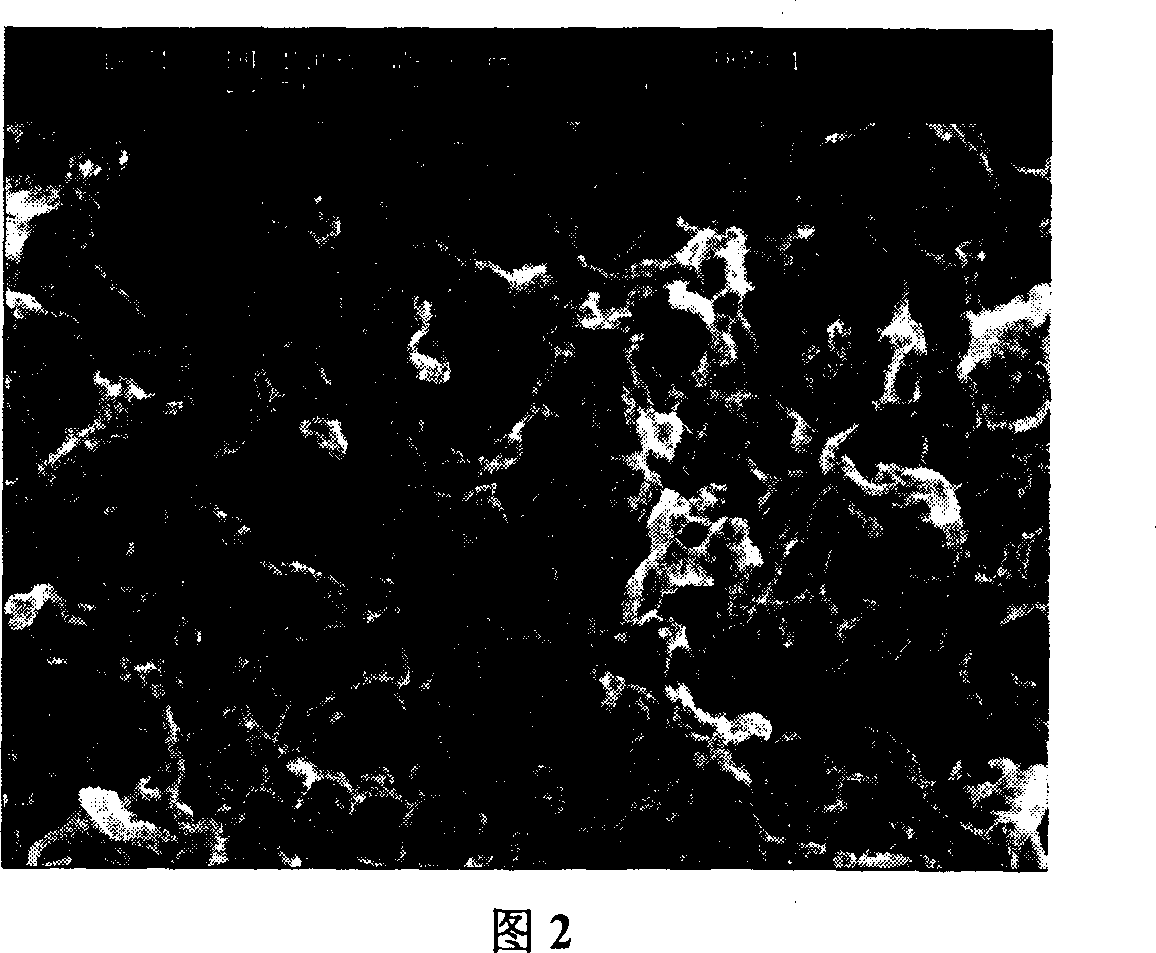

[0032](5) Forming a film, cooling to 25°C while stirring, casting the white casting liquid in a forming mold, and obtaining TiO after the solvent and non-solvent volatilize 2 / PVDF-HFP hybr...

Embodiment 3

[0036] (1) Prepare PVDF-HFP solution, weigh 0.5g PVDF-HFP and dissolve 6g in acetone, prepare PVDF-HFP colorless and transparent solution;

[0037] (2) prepare tetrabutyl titanate solution, weigh 0.3807g tetrabutyl titanate and dissolve in 2g n-butanol, prepare tetrabutyl titanate pale yellow solution;

[0038] (3) To adjust the pH value of the PVDF-HFP solution, add 0.15ml of 0.1mol / L hydrochloric acid solution dropwise to the PVDF-HFP solution;

[0039] (4) Prepare a composite casting solution. At 20° C., add the above-mentioned light yellow solution of tetrabutyl titanate dropwise to the stirred PVDF-HFP solution to gradually obtain a white mixed solution, raise the temperature to 40° C., and stir at a constant temperature for 8 hours. Obtain a viscous white uniform casting solution;

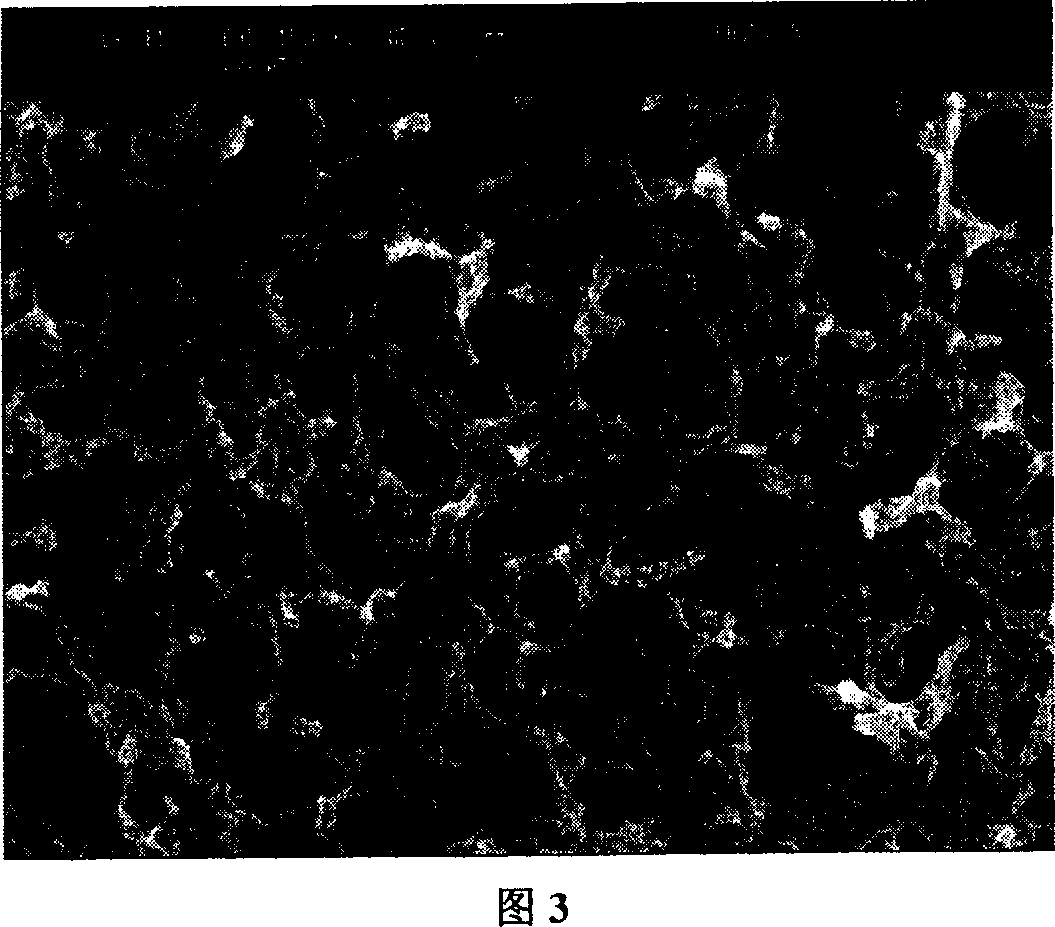

[0040] (5) Forming a film, cooling to 25°C while stirring, casting the white casting liquid in a forming mold, and obtaining TiO after the solvent and non-solvent volatilize 2 / PVDF-HFP hyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com