Heat treatment device of scissors products and its method

A heat treatment device and heat treatment method technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems of insufficient smoothness and hardness, sharp edges, etc., and achieve excellent surface technology, sharp edges, and improved heat treatment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

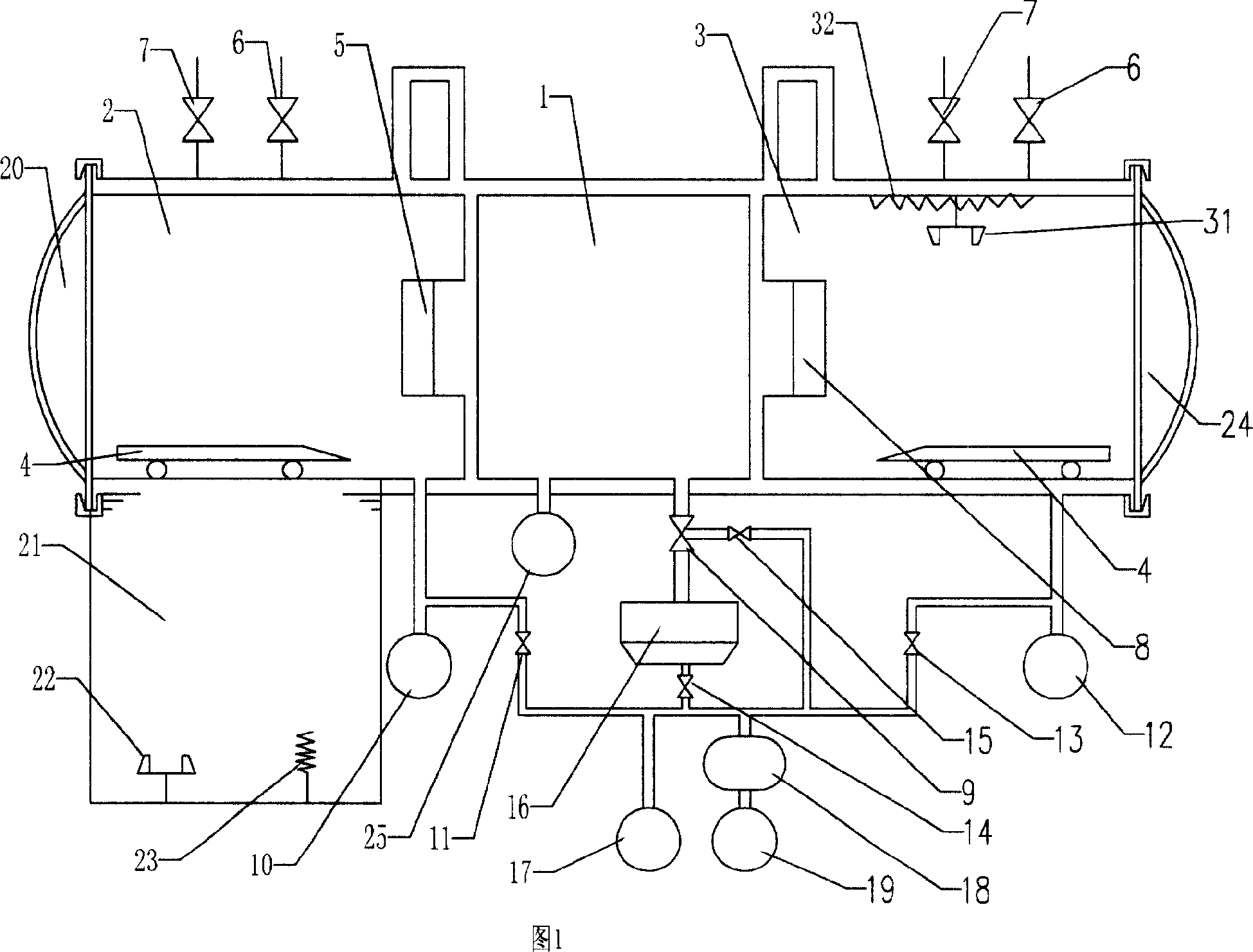

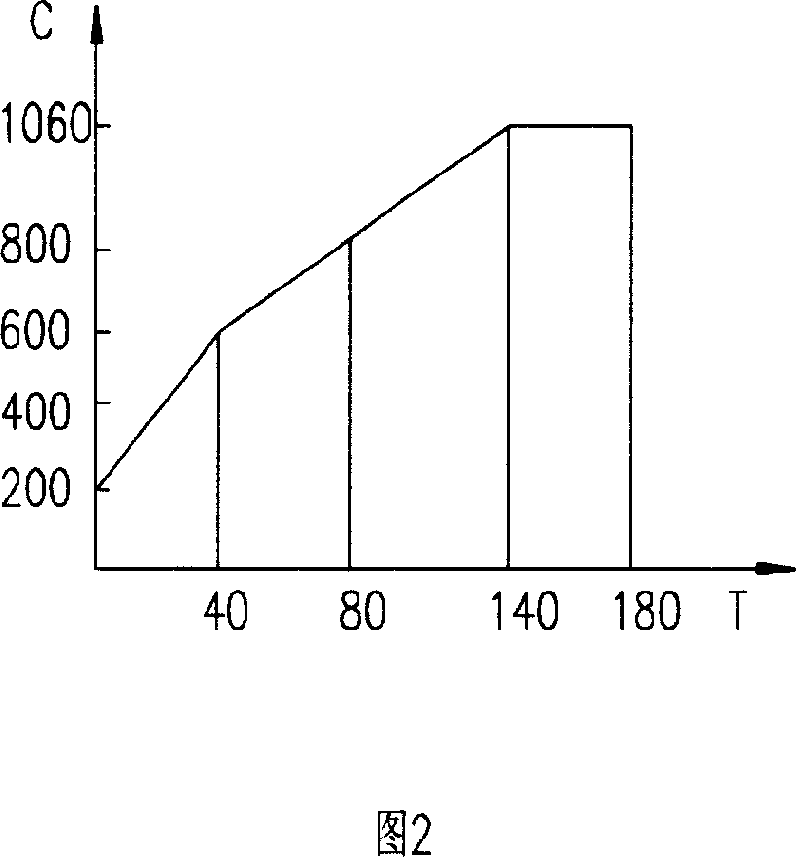

[0024] As shown in Figure 1, the vacuum heat treatment furnace includes a heating chamber 1, an oil quenching chamber 2, a gas quenching chamber 3, an electric control system, a quick transfer device, and an exhaust, gas charging system and cooling system connected to the heating chamber 1 and the cooling chamber The oil quenching chamber 2 and the gas quenching chamber 3 are respectively arranged at both ends of the heating chamber 1, the heating chamber 1 is connected with the oil quenching chamber 2 and the gas quenching chamber 3, and an insulating door 5, which can be opened and closed is arranged between the two. 8. The workpiece car 4 in the quick transfer device can pass through the insulation doors 5 and 8 to reciprocate between the heating chamber 1, the oil quenching chamber 2, and the gas quenching chamber 3. The electronic control system and the workpiece car 4, exhaust and inflation systems, The cooling system and the insulating doors 5, 8 are connected by mechani...

Embodiment 2

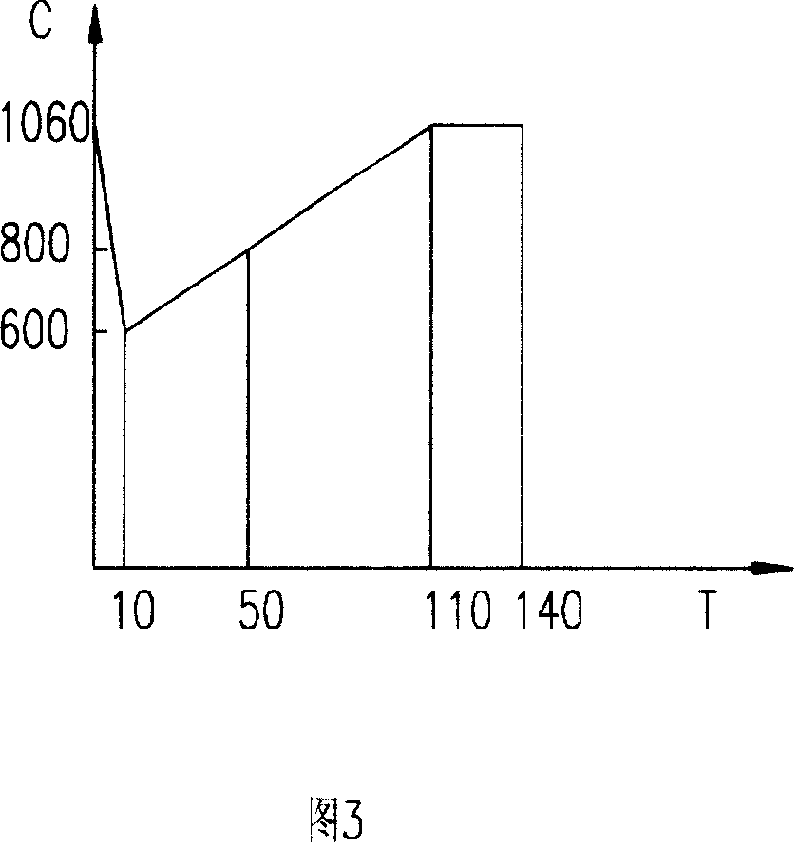

[0030] The difference between embodiment two and embodiment one is that the oil quenching is changed to gas quenching, and the operation process is basically the same as the oil quenching operation. That is to say, the workpiece is preheated from the gas quenching chamber 3, passes through the heating chamber 1 and then returns to the gas quenching chamber 3 for gas quenching. When the workpiece car 4 returns to the gas quenching chamber 3 from the high position of the heating chamber 1, close the middle insulation heat 8, and quickly fill in nitrogen gas. Up to 0.5Mpa, the high-pressure high-flow rate cold air circulation quenches the workpiece.

Embodiment 3

[0032] Compared with the first embodiment, the third embodiment differs in that the workpiece is preheated in the gas quenching chamber 3 and oil quenched in the oil quenching chamber 1 . That is to say, the workpiece enters from the gas quenching chamber 3, passes through the heating chamber 1, and then enters the oil quenching chamber 2 for oil quenching. When the workpiece car 4 enters the gas quenching chamber 3, the gas quenching chamber 3 is evacuated, and the heating chamber 1 is evacuated to not less than 1.33Pa. When the workpiece car 4 enters the oil quenching chamber 2 from the heating chamber 1, it is closed. The intermediate heat 5 fills the oil quenching chamber 2 with nitrogen from the inflation valve 7, and the nitrogen pressure is less than or equal to 0.16Mpa; at the same time, the workpiece car 4 is lowered into the oil tank, and the oil agitator 22 is started to oil quench the workpiece. After oil quenching finishes, workpiece car 4 rises, and oil agitator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com