Antipilling nitrilon and its production method

An anti-pilling acrylic fiber, production process technology, applied in textiles and papermaking, one-component synthetic polymer rayon, fiber chemical characteristics, etc. Poor durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

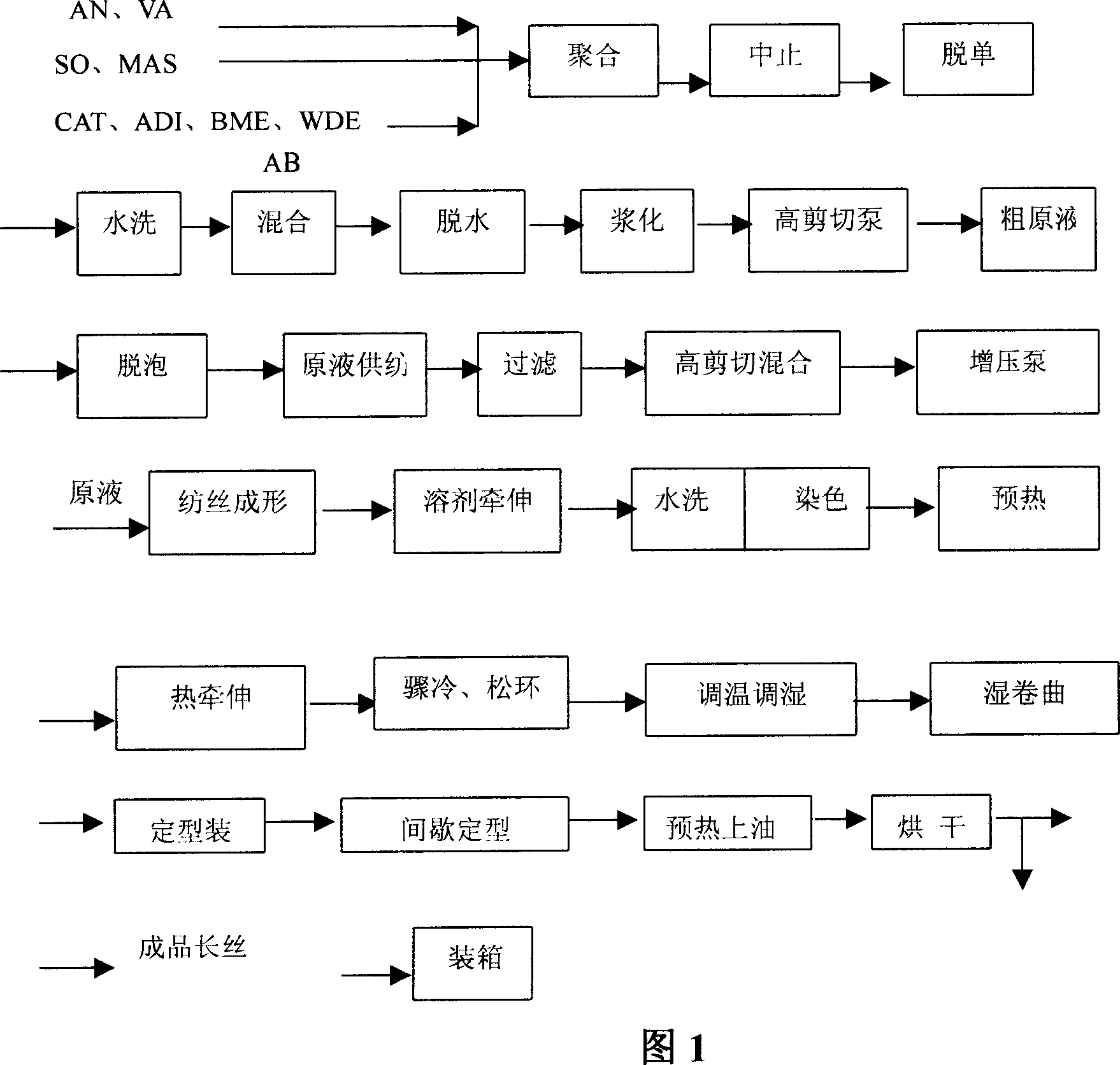

Method used

Image

Examples

Embodiment 1

[0023] Anti-pilling fiber pilot test:

[0024] The production of polymer A, the specific parameters of A polymer are shown in Table 4, and the reaction is carried out in a continuous reactor with a jacket of pure aluminum, and the feed amount of the reactant is accurately measured by a mass flow meter. The solid concentration is 28%, the reaction temperature is 65°C, the pH value in the kettle is 3.0, and the conversion rate is 85%. The jacket is cooled with chilled water to remove the heat generated by the reaction. Remove the monomer, wash it into the polymer and mix it;

[0025] For the production of polymer B, change the parameters of B set after 7 hours of production of polymer A to produce polymer B. The specific parameters are shown in Table 5. The preparation method and process conditions are the same as those of polymer A;

[0026] A and B two kinds of polymers are mixed in a mixing tank at a ratio of 1:1 to produce stock solution;

[0027] Dehydration and pulping s...

Embodiment 2

[0045] Acrylonitrile copolymer A with acrylonitrile content of 95%, vinyl acetate content of 5%, viscosity average molecular weight of 35000-50000 and acrylonitrile content of 85%, vinyl acetate content of 14%, viscosity average molecular weight of 50000-50000 For 60000 acrylonitrile copolymer B, the two polymers A and B are mixed in a ratio of 1:1.5.

[0046]The reactions were all carried out in a jacketed continuous reaction kettle of pure aluminum, the total monomer concentration of the feed was 35%, the reaction temperature was 55°C, the pH value in the kettle was 2.0, and the conversion rate was 75%. Chilled water is used for cooling to remove the heat generated by the reaction; the reacted polymer is terminated by reaction, the monomer is released, washed with water and mixed with the polymer; the mixed polymer is dehydrated and dissolved with sodium thiocyanate to prepare a polymer The raw material content is 13.5%, and the crude stock solution is extracted by air bubbl...

Embodiment 3

[0048] 91% acrylonitrile and 91% vinyl acetate? 9%, acrylonitrile copolymer A with a viscosity-average molecular weight of 35,000-50,000 and an acrylonitrile content of 91%, and a vinyl acetate content of ? 9%, an acrylonitrile copolymer B with a viscosity-average molecular weight of 50,000-60,000, and two polymers A and B in a ratio of 1:2.

[0049] The reactions were all carried out in a jacketed continuous reaction kettle of pure aluminum, the total monomer concentration of the feed was 30%, the reaction temperature was 60°C, the pH value in the kettle was 2.5, and the conversion rate was 80%. Chilled water is used for cooling to remove the heat generated by the reaction; the reacted polymer is terminated by reaction, the monomer is released, washed with water and mixed with the polymer; the mixed polymer is dehydrated and dissolved with sodium thiocyanate to prepare a polymer The raw material content is 13.5%, and the crude stock solution is released through air bubbles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com