Insulating film forming composition, preparing method thereof, silica dioxide insulating film and preparing method thereof

A technology of insulating film and composition, which is applied in the manufacture of organic insulators, plastic/resin/wax insulators, semiconductors/solid state devices, etc., and can solve problems such as unsuitable for long-term storage, poor substrate adhesion, and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

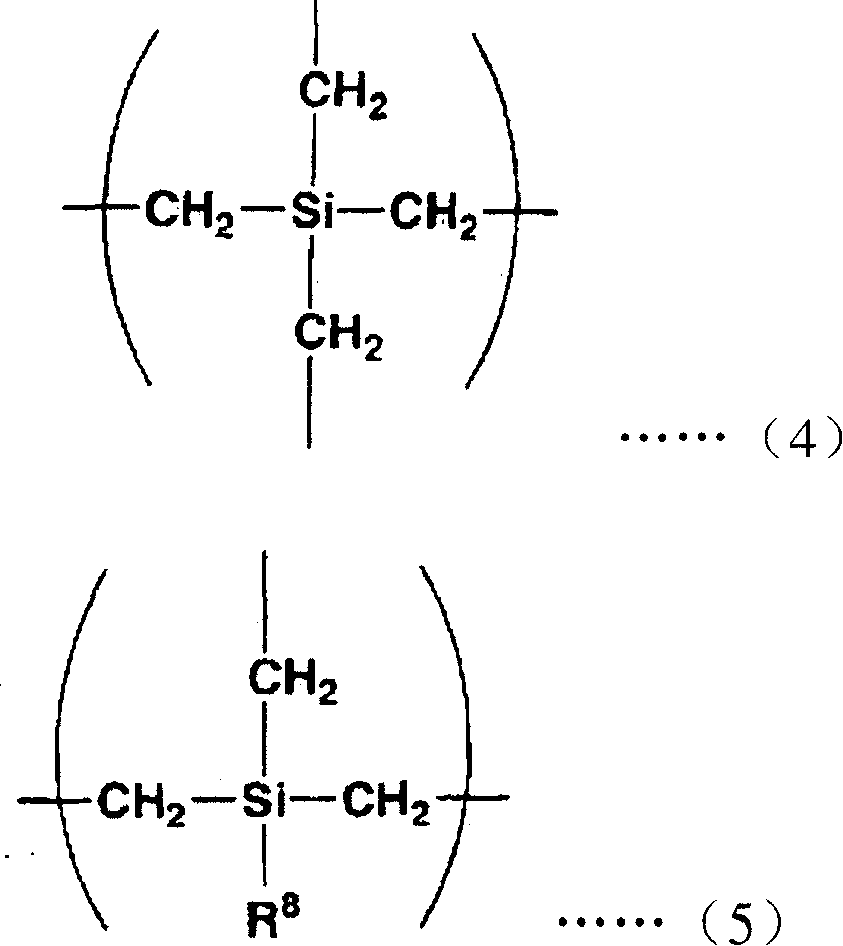

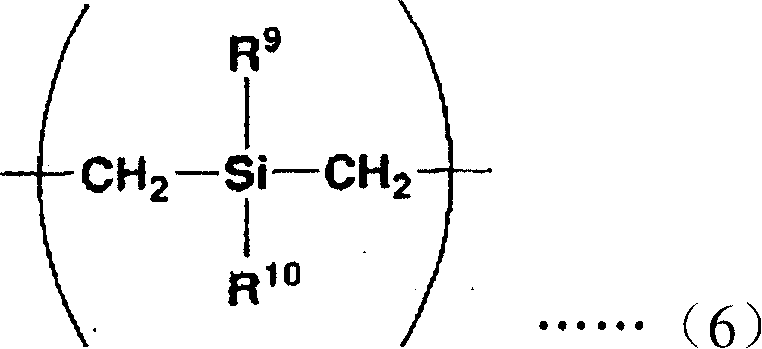

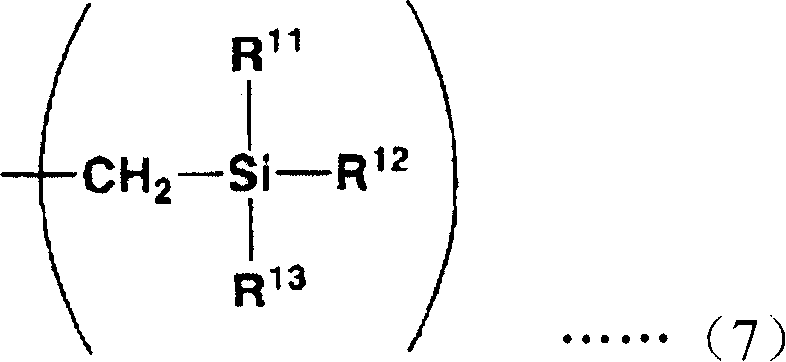

[0172] 52.15 g of aqueous solutions of 20% tetrapropylammonium hydroxide, 81.5 g of ultrapure water, and 470.36 g of isopropanol were weighed into a quartz flask equipped with a condenser, and stirred at 60°C. Next, after adding 26.24 g of methyltrimethoxysilane, 50.93 g of tetrapropoxysilane, and 18.82 g of polycarbosilane (10) (Mw=840) having structures shown in Table 2 below in the following proportions, at 60 The mixture was stirred at °C for 4 hours to obtain a reaction solution containing a hydrolysis condensate having a weight average molecular weight of 55,000 in terms of polystyrene. After cooling the reaction liquid to room temperature, 551.86 g of propylene glycol monopropyl ether and 35.42 g of 20% acetic acid aqueous solution were added. This reaction solution was concentrated under reduced pressure until the solid content concentration reached 10%, whereby a film-forming composition 2 was obtained.

[0173] [Table 2]

[0174]

Embodiment 3

[0176] 5.80 g of aqueous solutions of 25% tetramethylammonium hydroxide, 110.30 g of ultrapure water, and 548.08 g of ethanol were weighed into a quartz flask equipped with a condenser, and stirred at 60°C. Next, 5.70 g of dimethyldimethoxysilane, 16.15 g of methyltrimethoxysilane, 10.83 g of tetramethoxysilane, and polycarbonate having the structures shown in the following Table 3 were added continuously for 1 hour. After 3.14 g of silane (11) (Mw=1050), it stirred at 60 degreeC for 2 hours, and obtained the reaction liquid containing the hydrolysis-condensation product whose weight average molecular weight in conversion of polystyrene was 40000. After cooling the reaction liquid to room temperature, 658.38 g of propylene glycol monopropyl ether and 10.98 g of 20% acetic acid aqueous solution were added. The reaction solution was concentrated under reduced pressure until the solid content concentration reached 10%, whereby a film-forming composition 3 was obtained.

[0177] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com