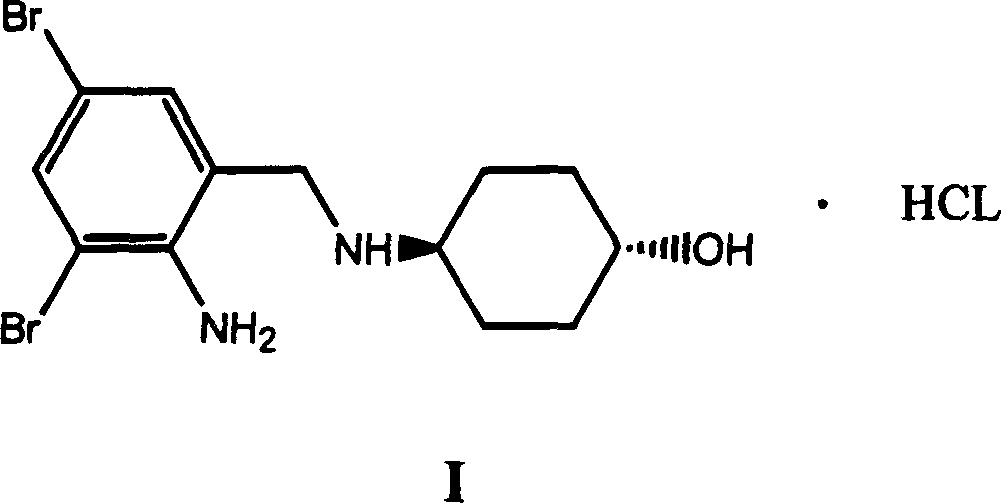

High dose Ambroxol hydrochloride freeze-dried preparation and preparation method

A technology for ambroxol hydrochloride and freeze-dried preparations, which is applied in the field of high-dose ambroxol hydrochloride freeze-dried preparations and its preparation, and can solve the problems of insufficient solubility and difficulties of ambroxol hydrochloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of a lyophilized preparation containing 250 mg of ambroxol hydrochloride per bottle

[0035] The composition of the preparation containing 250mg of ambroxol hydrochloride per bottle:

[0036] Ambroxol hydrochloride 250g

[0037] Xylitol 150g

[0038] Anhydrous citric acid 50g

[0040] Dissolve in water for injection and dilute to 5000ml

[0041] 1000 bottles

[0042] In water for injection, add xylitol, anhydrous citric acid, sodium hydroxide, stir and dissolve. Add micronized ambroxol hydrochloride to the solution, heat to 70°C, dissolve, cool, and dilute to 5000ml with water for injection. The pH of the resulting solution is 5.0. Decolorization with activated carbon, sterile filtration through 0.22μm microporous membrane, 5ml aliquoted into cillin bottles, freeze-dried, the highest drying temperature can reach 45 ℃, each bottle contains 250mg of ambroxol hydrochloride freeze-dried product. Add 1...

Embodiment 2

[0043]Example 2 Preparation of a lyophilized preparation containing 200 mg of ambroxol hydrochloride per bottle

[0044] The composition of each bottle containing 200mg of ambroxol hydrochloride:

[0045] Ambroxol hydrochloride 200g

[0046] Mannitol 200g

[0047] Sodium dihydrogen phosphate 50g

[0049] Dissolve in water for injection and dilute to 5000ml

[0050] 1000 bottles

[0051] In water for injection, add mannitol, anhydrous citric acid, sodium hydroxide, stir and dissolve. Add micronized ambroxol hydrochloride to the solution, heat to 70°C, dissolve, cool, and dilute to 5000ml with water for injection. The pH of the resulting solution is 4.5. The subsequent process is the same as in Example 1. Each bottle contains 200mg of ambroxol hydrochloride lyophilized product. Add 10ml of water for injection to this product, it will be completely dissolved in about 20 seconds, the solution is clear, and the pH = 4.6.

Embodiment 3

[0052] Example 3 Preparation of a lyophilized preparation containing 200 mg of ambroxol hydrochloride per bottle

[0053] The composition of each bottle containing 200mg of ambroxol hydrochloride:

[0054] Ambroxol hydrochloride 200g

[0055] Xylitol 150g

[0056] Anhydrous citric acid 38g

[0057] Sodium hydroxide 16g

[0058] Dissolve in water for injection and dilute to 5000ml

[0059] 1000 bottles

[0060] The preparation process is the same as in Example 1. The pH of the solution after constant volume is 5.0. Add 10ml of water for injection to this product, it will be completely dissolved in about 20 seconds, the solution is clear, and the pH=5.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com