System and method for automatic adding flocculant

A technology of automatic addition and flocculant, applied in separation methods, chemical instruments and methods, precipitation separation, etc., can solve the problems of water source and flocculant waste, lack of coal slime water concentration and flow feedforward detection system, etc., to reduce overflow water Concentration, improving the yield of clean coal, saving the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

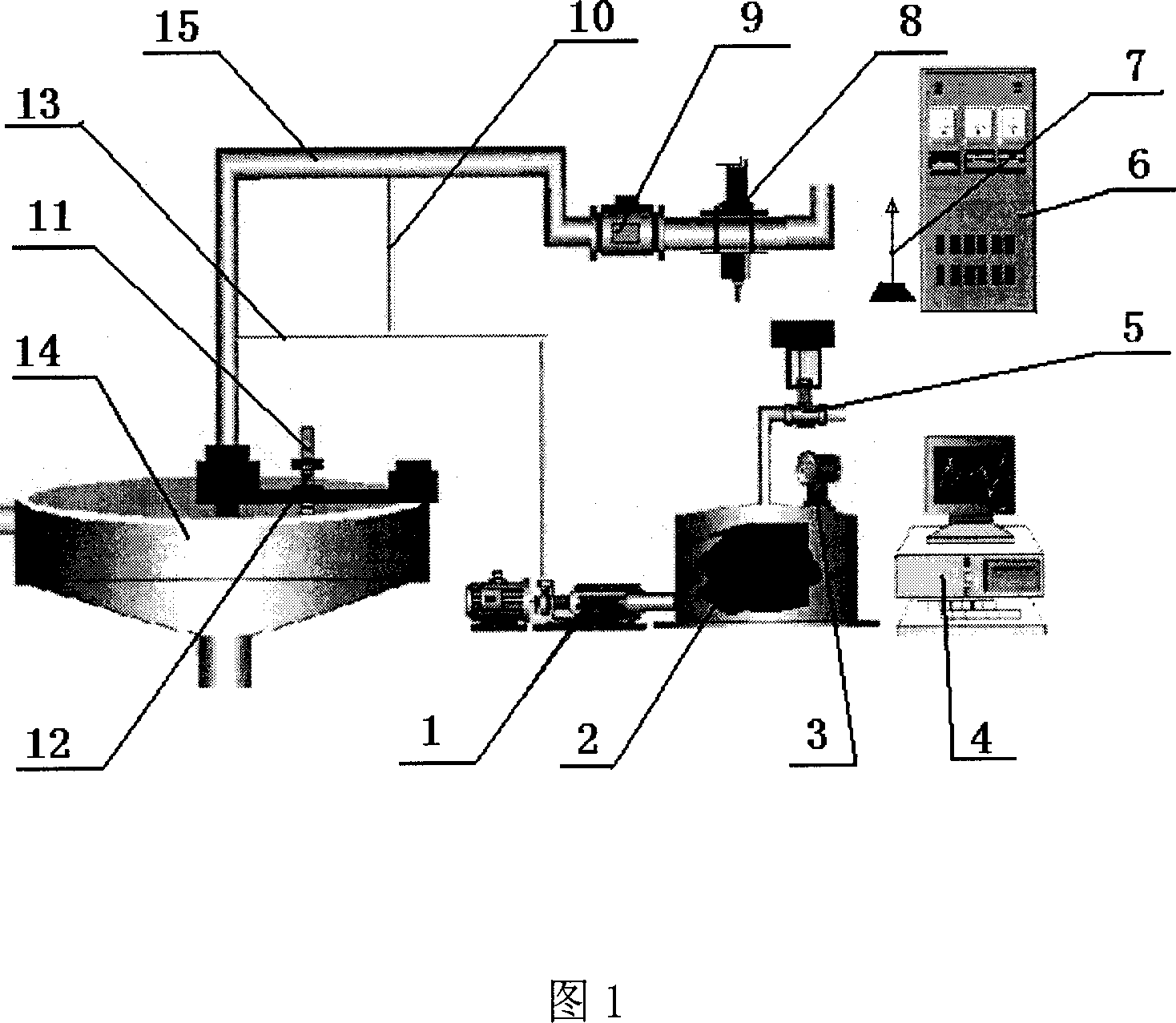

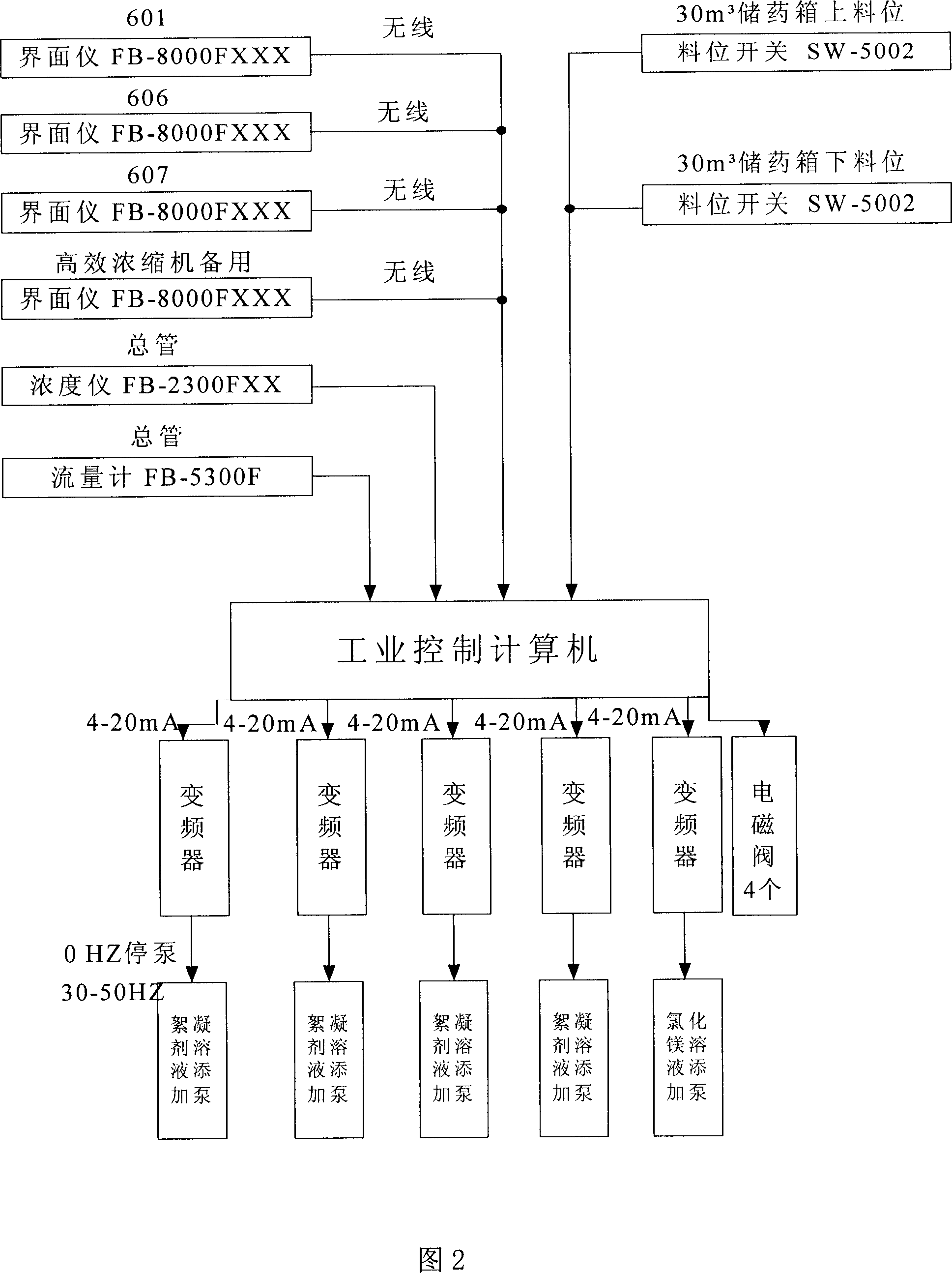

[0019] The specific embodiment of the automatic flocculant adding system of the present invention includes: a dosing part, a main pipe flow concentration detection part, a coal slime interface detection part, and a control part.

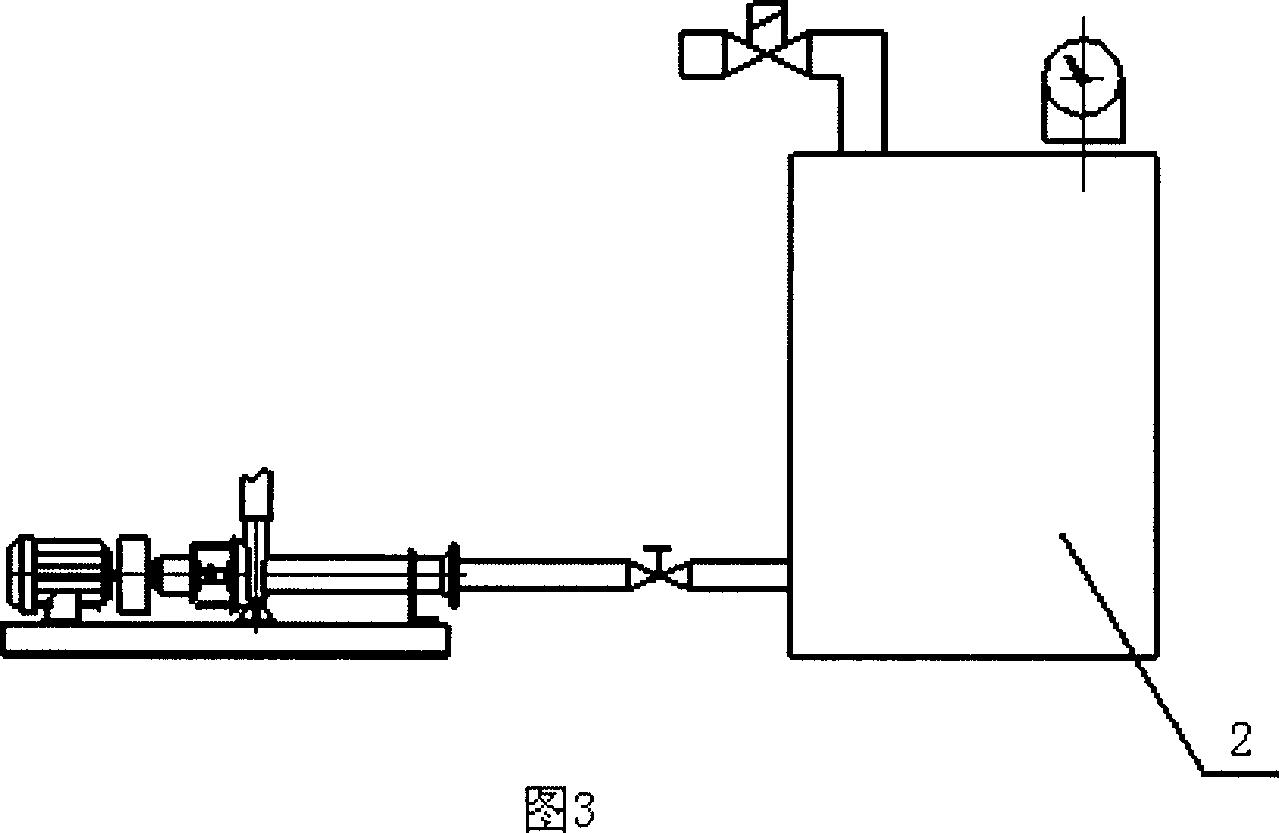

[0020] Embodiments In Fig. 3 and Fig. 4, the dosing part mainly includes: a three-phase motor 16, a metering screw pump 1, a medicine storage tank 2, a liquid level sensor 3, an electric ball valve, and valve pipes. The three-phase motor 16 and the metering screw pump 1 are a set of screw pumps composed of one or more sets. The metering screw pump 1 is the main pipe dosing pipe 10 connected with the medicine storage box 2 through the pipeline and the stop valve, and the metering screw pump 16 sucks the flocculant solution from the medicine storage box through the concentration tank dosing pipe 13 and the slime water feeding pipe 15 and Slime water mix. The capacitive liquid level sensor or the ultrasonic liquid level sensor 3 is used to measure the ...

Embodiment approach 2

[0026] The present invention is used for the adding method of flocculant automatic adding system, in embodiment Fig. 1, at first detect the concentration and the flow rate of the coal slime water in the coal slime water feeding pipe 15 by main pipe concentration meter 8 and main pipe flowmeter 9, by industrial control machine 4 Calculate the amount of dry coal slime that will be added to the thickening tank, and control the frequency converter according to the amount of dry coal slime. The frequency converter controls the speed of the main pipe dosing motor 16, and the main pipe dosing motor 16 drives the screw pump 1 , The screw pump 1 discharges a certain amount of flocculant and is added to the slime water feed pipe 15 from the main pipe dosing pipe 10, that is, the feed-forward dosing part, forming a rough control of the flocculant. A liquid level sensor 3 and an electric ball valve 5 are installed in the medicine storage tank 2. When the liquid level is detected to be low,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com